Capacitive coupling device and filter containing capacitive coupling device

A capacitive coupling and negative coupling technology, applied in the direction of connecting devices, waveguide devices, electrical components, etc., can solve the problems of consuming man-hours, increasing the production process of dielectric filters, etc., to achieve convenient processing, convenient processing and manufacturing, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

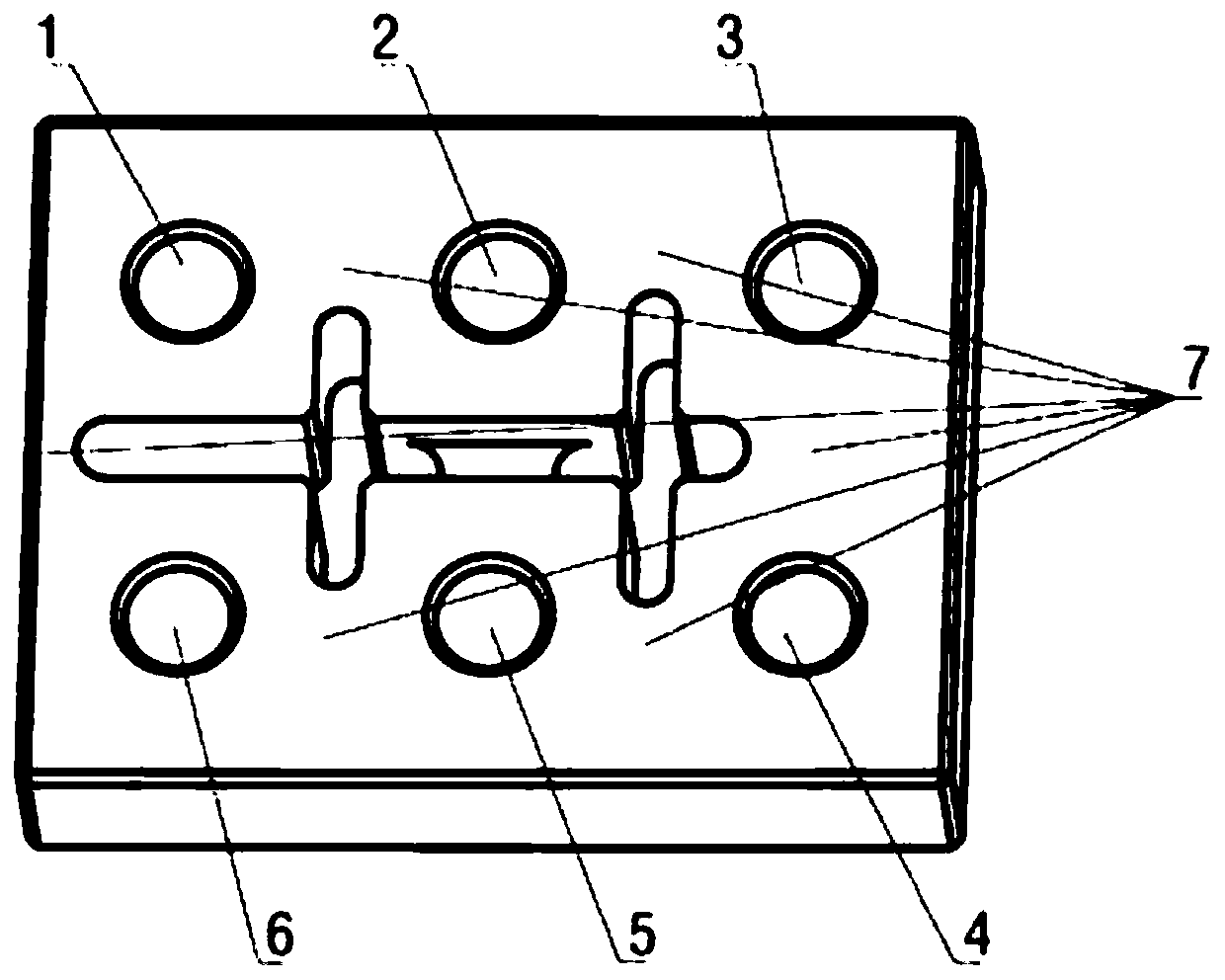

[0044] Attached by the description of the present invention Figure 1-4 It can be seen that the present invention discloses a capacitive coupling device, which includes a dielectric body, and six resonant frequency tuning holes are processed on the top surface of the dielectric body, namely the first resonant frequency tuning hole 1 and the second resonant frequency tuning hole 2 , the third resonant frequency tuning hole 3, the fourth resonant frequency tuning hole 4, the fifth resonant frequency tuning hole 5 and the sixth resonant frequency tuning hole 6, the six resonant frequency tuning holes are integrally formed, the first resonant frequency tuning hole 1 between the second resonance frequency tuning hole 2, between the second resonance frequency tuning hole 2 and the third resonance frequency tuning hole 3, between the third resonance frequency tuning hole 3 and the fourth resonance frequency tuning hole 4, and the fourth resonance Between the frequency tuning hole 4 a...

Embodiment 2

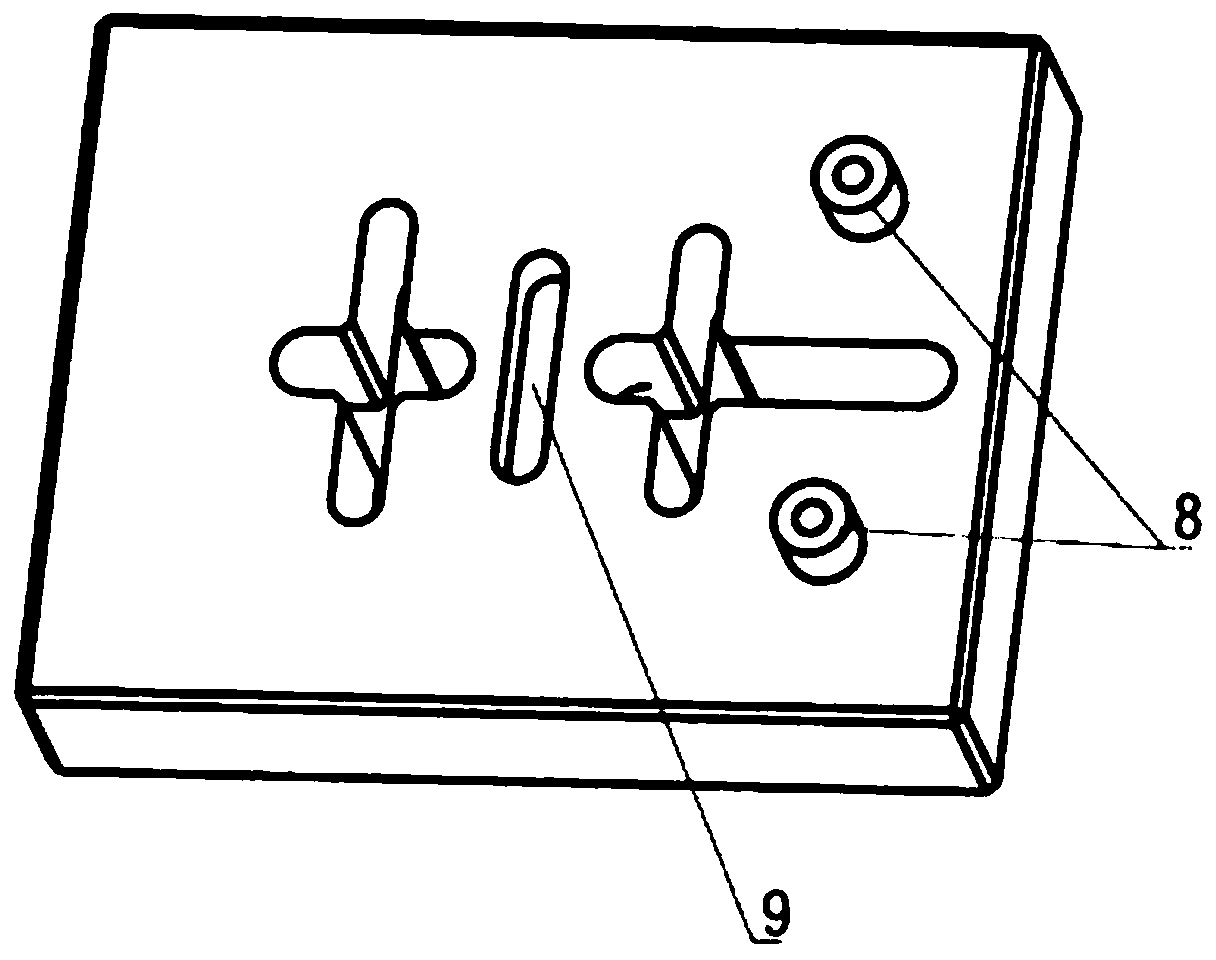

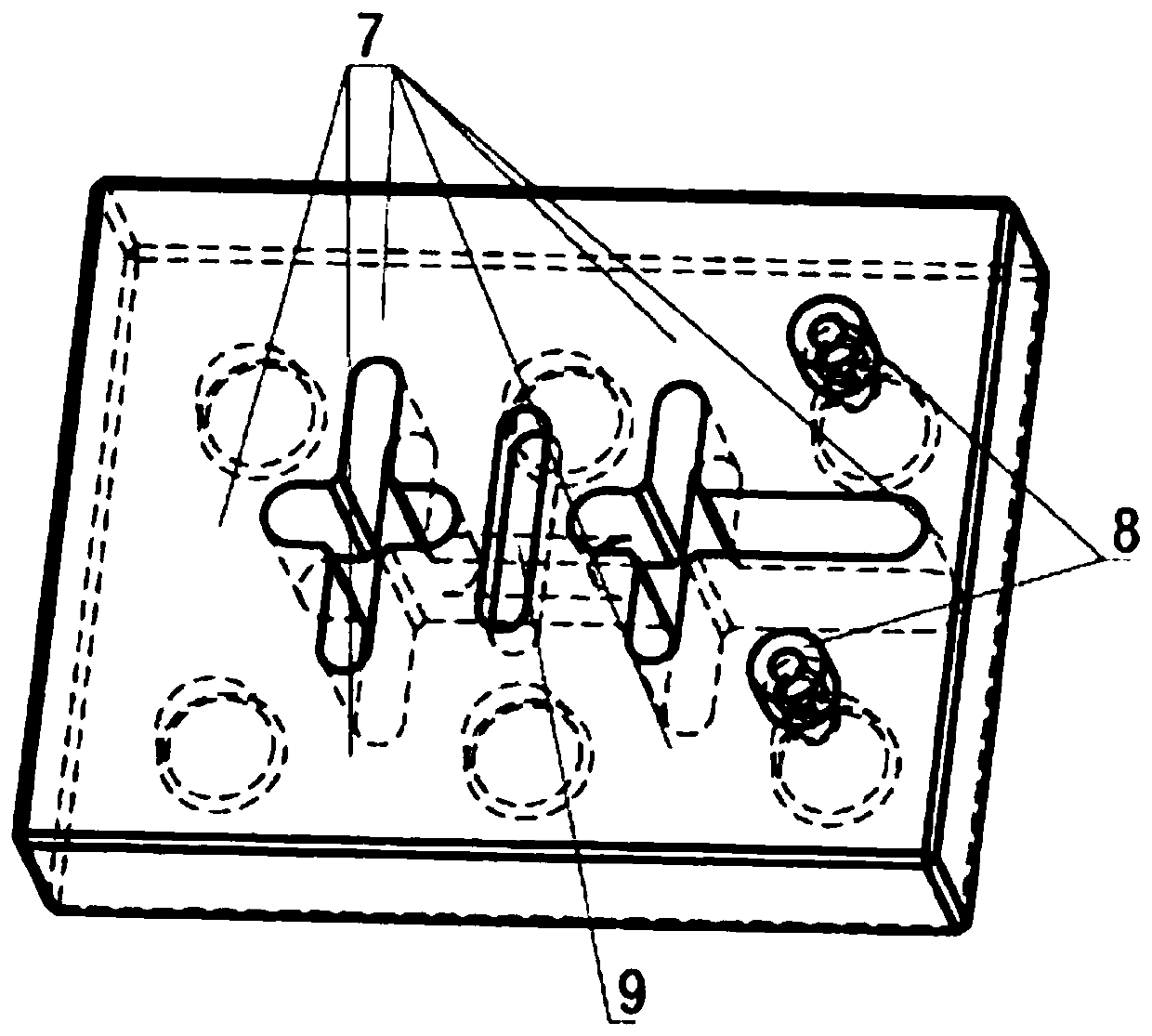

[0048] Attached by the description of the present invention Figure 6-8 It can be seen that the present invention discloses a capacitive coupling device, which includes a dielectric body, six resonant frequency tuning holes are processed on the top surface of the dielectric body, and an inductive coupling structure 7 is arranged between two adjacent resonant frequency tuning holes. The coupling structure 7 is a cross-shaped through hole, and a negative coupling groove 9 is also processed on the top surface of the dielectric body. The negative coupling groove 9 is a circular through hole, and the negative coupling groove 9 is located in the middle of the two adjacent resonance frequency tuning holes. Between, the outer surface of the dielectric body and the inner surfaces of the six resonant frequency tuning holes are plated with the first conductive metal layer, the inner surface of the negative coupling groove 9 is plated with the second metal conductive layer, and the two neg...

Embodiment 3

[0050] Attached by the description of the present invention Figure 9 It can be seen that the present invention discloses a capacitive coupling device, which includes a dielectric body, six resonant frequency tuning holes are processed on the top surface of the dielectric body, and an inductive coupling structure 7 is arranged between two adjacent resonant frequency tuning holes. The coupling structure 7 is a cross-shaped through hole, and a negative coupling groove 9 is also processed on the top surface of the dielectric body. The negative coupling groove 9 is a circular blind hole, and the negative coupling groove 9 is located in the middle of the two adjacent resonance frequency tuning holes. Between, the outer surface of the dielectric body and the inner surface of the 6 resonant frequency tuning holes are plated with the first metal conductive layer, the inner surface of the negative coupling groove 9 is plated with the second metal conductive layer, the notch of the negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com