Rotor of rotating electrical machine

A technology for rotating electrical machines and rotors, which is applied in the field of rotors, and can solve problems such as end plate 105, rotor shaft 101 offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

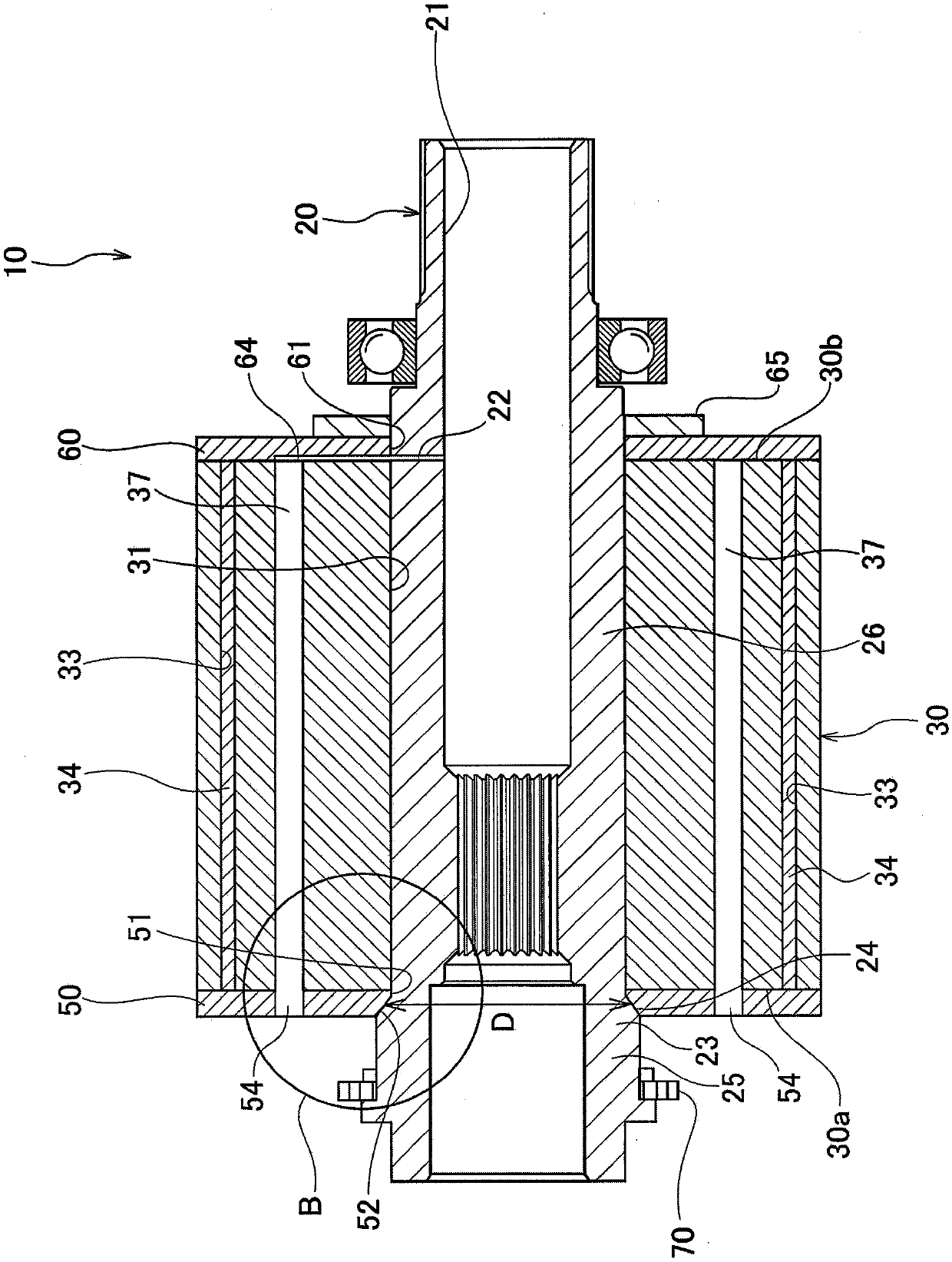

[0044] Below, refer to Figures 1 to 4B , the rotor of the rotating electric machine according to one embodiment of the present invention will be described.

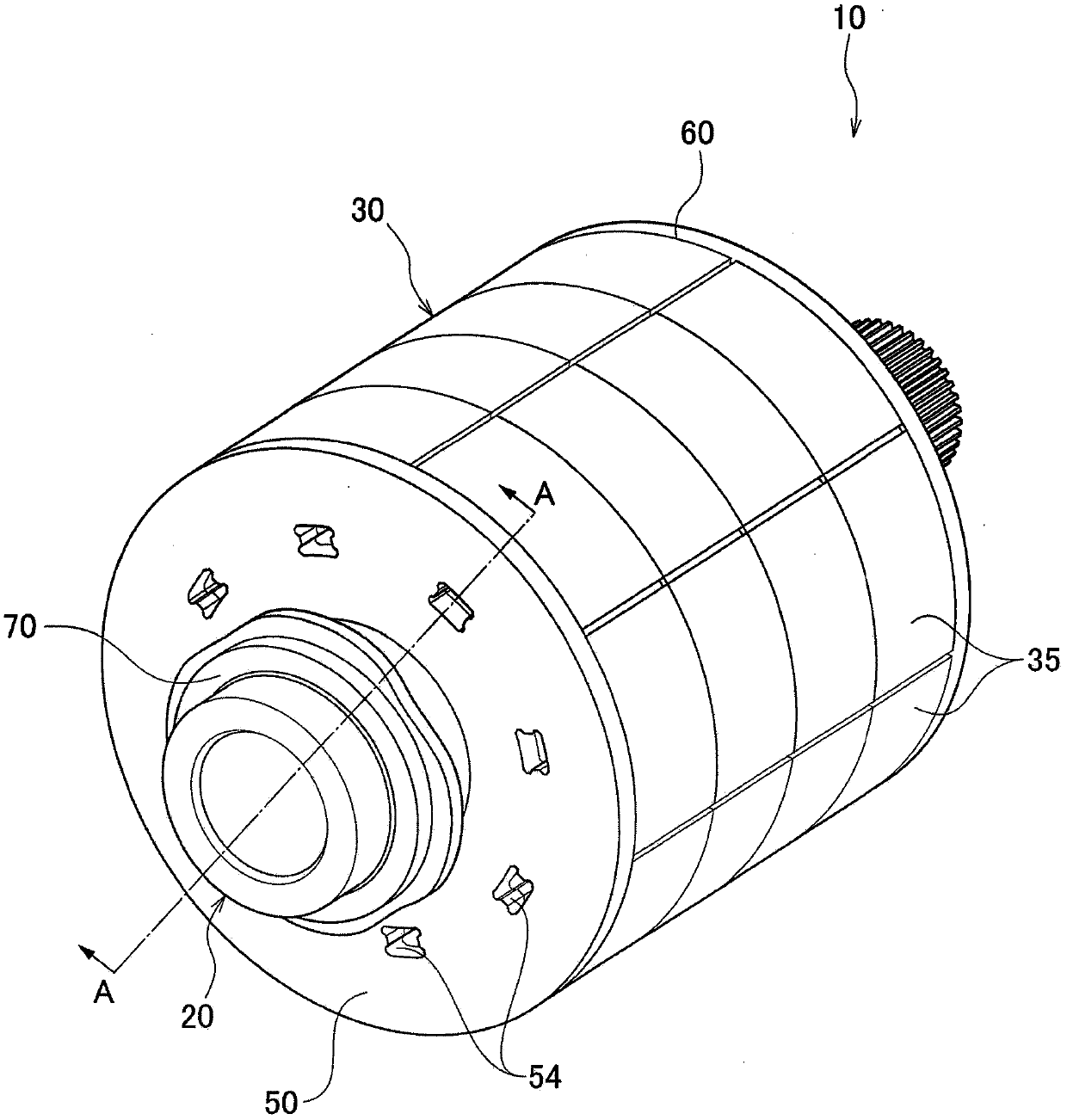

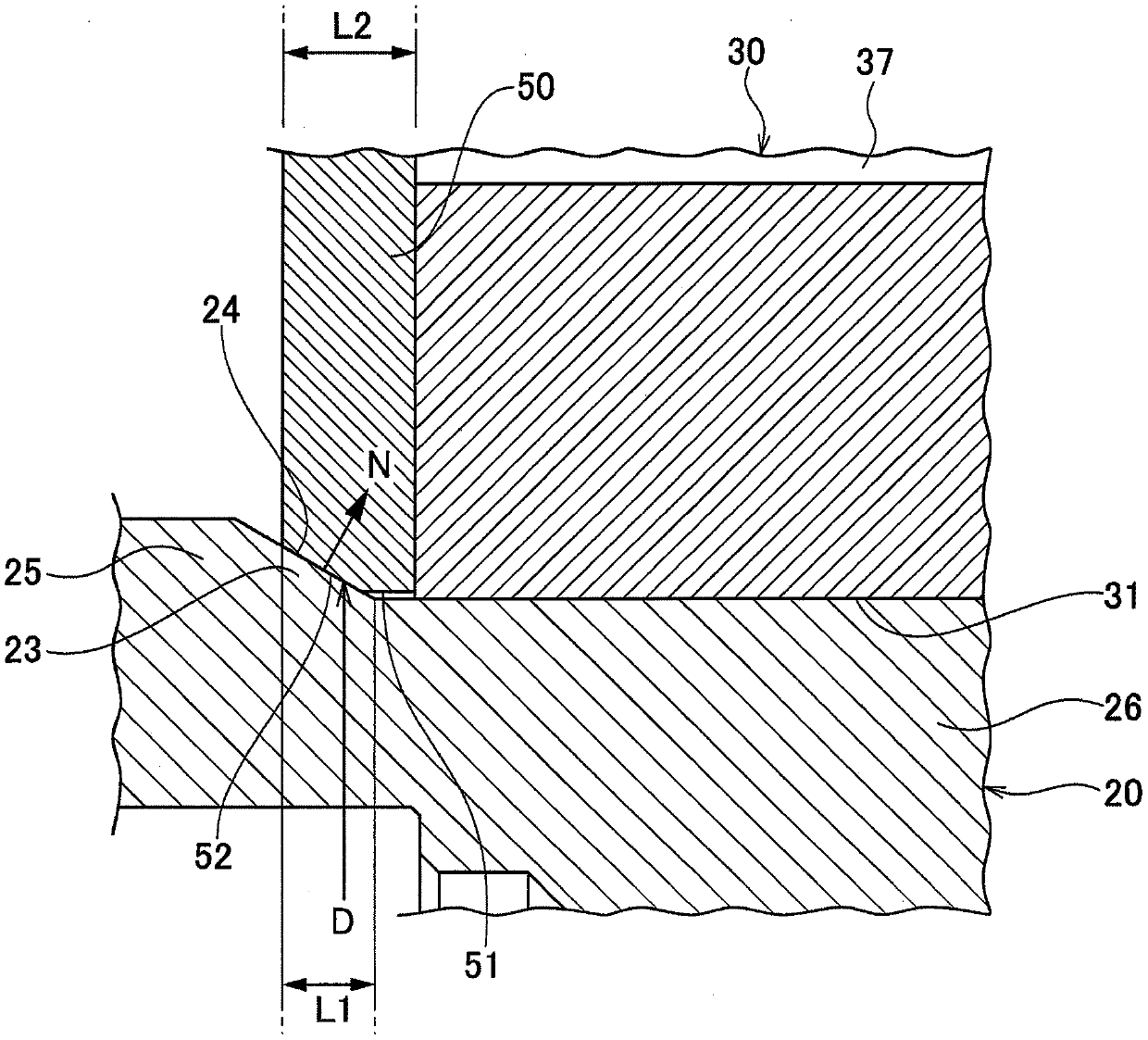

[0045] Such as figure 1 and figure 2 As shown, the rotor 10 of the rotating electric machine according to this embodiment includes: a rotor shaft 20; a rotor yoke 30 press-fitted into the outer peripheral portion of the rotor shaft 20; side; the second end plate 60 is disposed on the other axial side of the rotor yoke 30 ; and the resolver 70 detects the rotation angle of the rotor 10 .

[0046] In the rotor shaft 20 , a cooling flow path 21 through which the refrigerant flows is formed inside. The cooling flow path 21 extends in the axial direction inside the rotor shaft 20 and is configured to be capable of supplying a refrigerant from the outside. As the refrigerant, for example, ATF (Automatic Transmission Fluid) is used, and a supply path is formed so that ATF circulates between the transmission case and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com