Semi-automatic multi-angle workpiece drilling device

A drilling device and multi-angle technology, applied in the field of workpiece processing, can solve the problems of high purchase cost and use cost of CNC machine tools, low added value workpiece processing is not economical, etc., and achieves good adjustability, convenient adjustment, and satisfying drilling The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

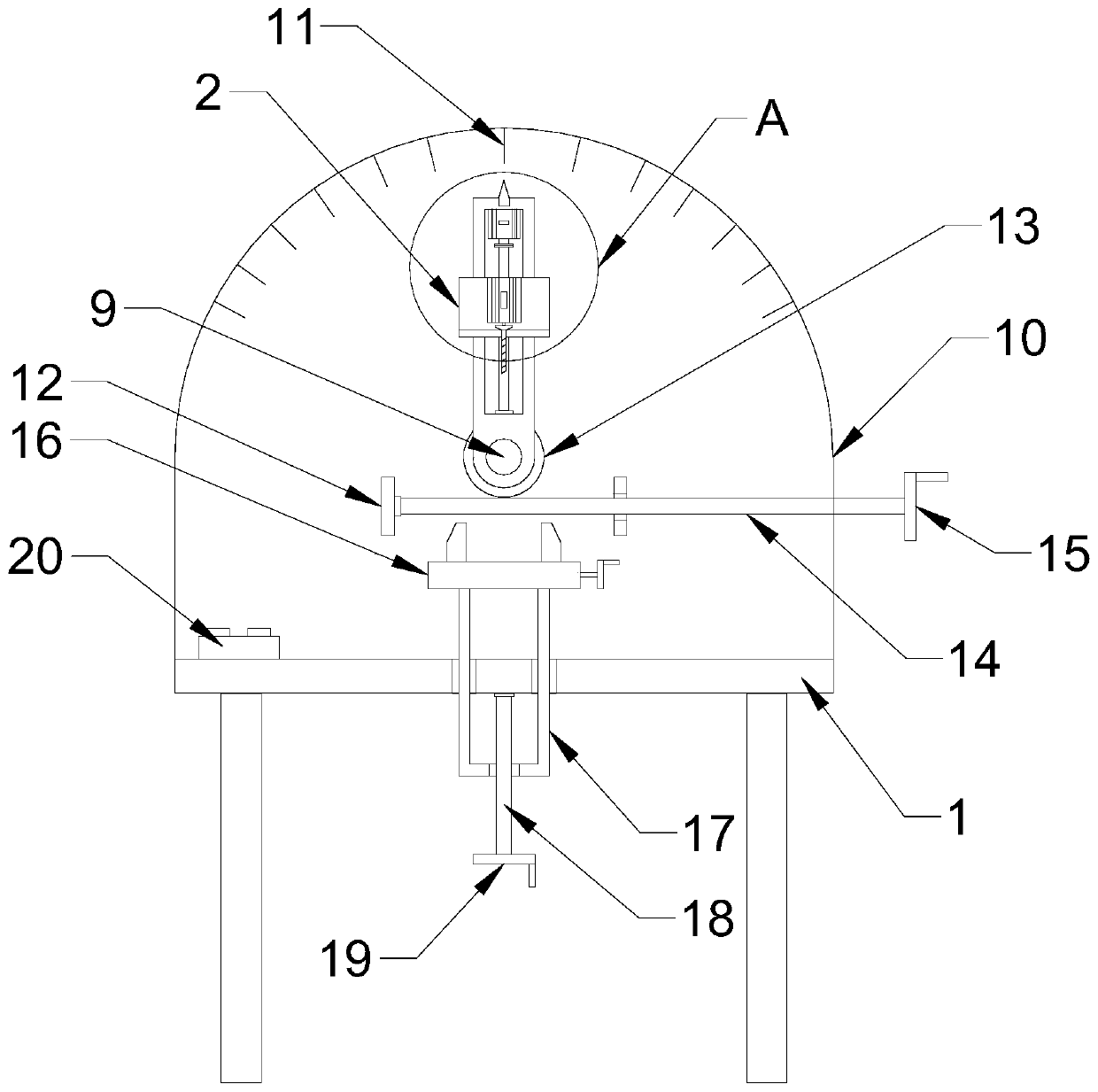

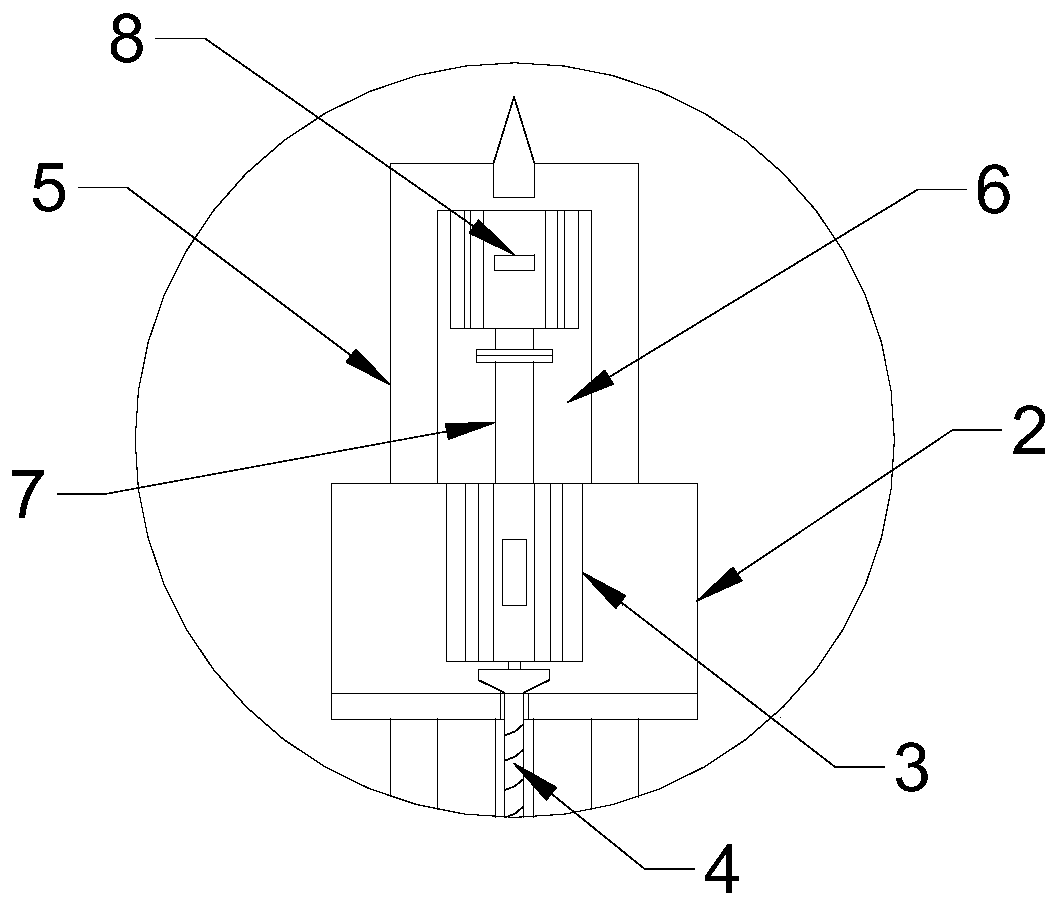

[0021] see Figure 1-4 , in an embodiment of the present invention, a semi-automatic multi-angle workpiece drilling device includes a workbench 1 and a drilling motor 3, and the front end of the drilling motor 3 is clamped with a drill rod 4 through a snap joint; the drilling motor 3 is connected by a bolt Fixedly connected with a moving seat 2, the moving seat 2 is nested with a swing plate 5, the swing plate 5 is provided with a rectangular groove 6, and the moving seat 2 is nested in the rectangular groove 6; the rectangular groove 6 is provided with a first screw rod 7 , the first screw mandrel 7 runs through the moving seat 2 and is threadedly connected with the moving seat 2; the first screw mandrel 7 is connected with a screw mandrel motor 8 through a coupling, and the screw mandrel motor 8 drives the first screw mandrel 7 to rotate. The screw mandrel 7 drives the moving seat 2 to move in the rectangular groove 6, thereby realizing the feeding of the drill rod 4.

[00...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is that: the workbench 1 is provided with a clamping seat 16, which clamps the workpiece; the lower end of the clamping seat 16 is fixedly connected with a lifting frame 17, and the lifting frame 17 runs through the workbench 1, the lifting frame 17 runs through and is threadedly connected with a second screw rod 18, the lower end of the second screw rod 18 is fixedly connected with a second adjusting wheel 19, and the second adjusting wheel 19 is rotated to adjust the height of the clamping seat 16. Then adjust the drilling depth.

[0025] One side of the workbench 1 is fixedly connected with a switch panel 20, and the switch panel 20 is provided with a start switch of the screw motor 8 and the drilling motor 3, which is convenient for starting the screw motor 8 and the drilling motor 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com