Movable clamping working table for round steel machining

A mobile and workbench technology, applied in the direction of metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of inconvenient movement, slow clamping speed, difficulty in meeting people's daily processing needs, etc., to solve the problem of clamping speed Slow, fast clamping speed, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

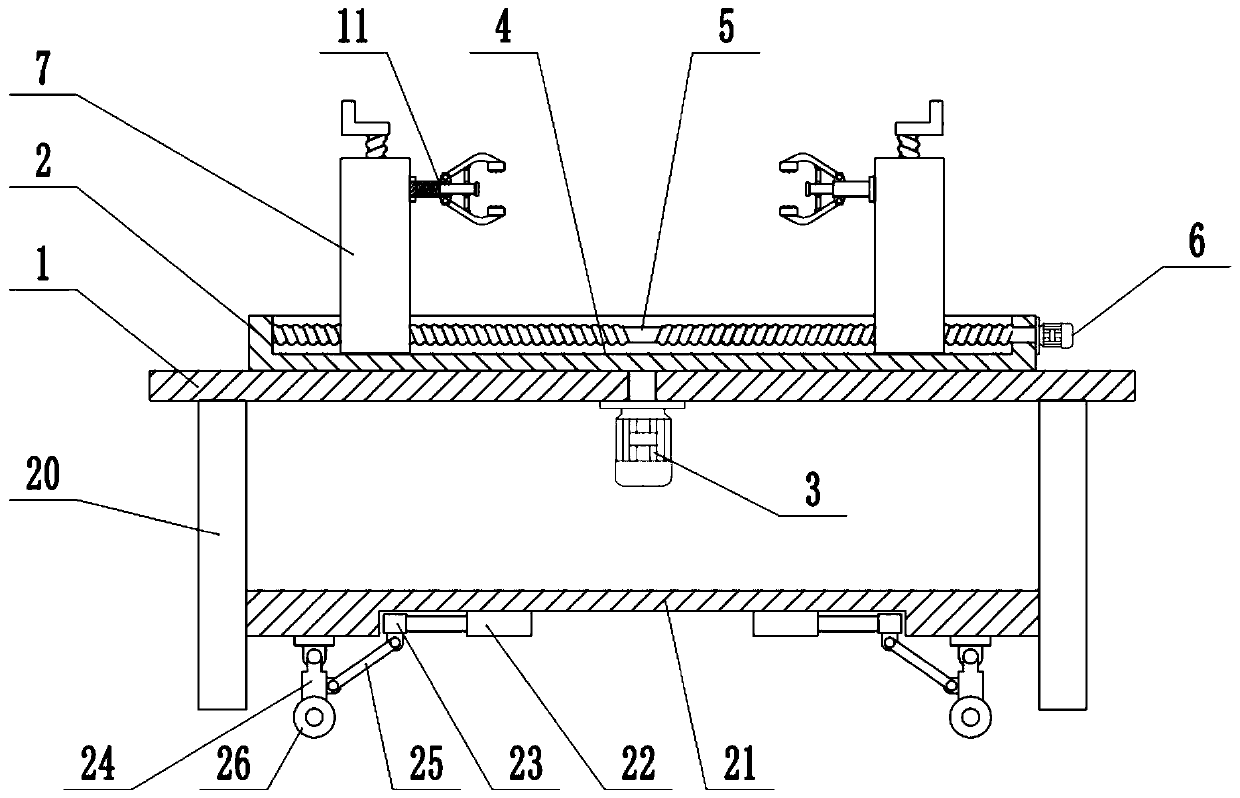

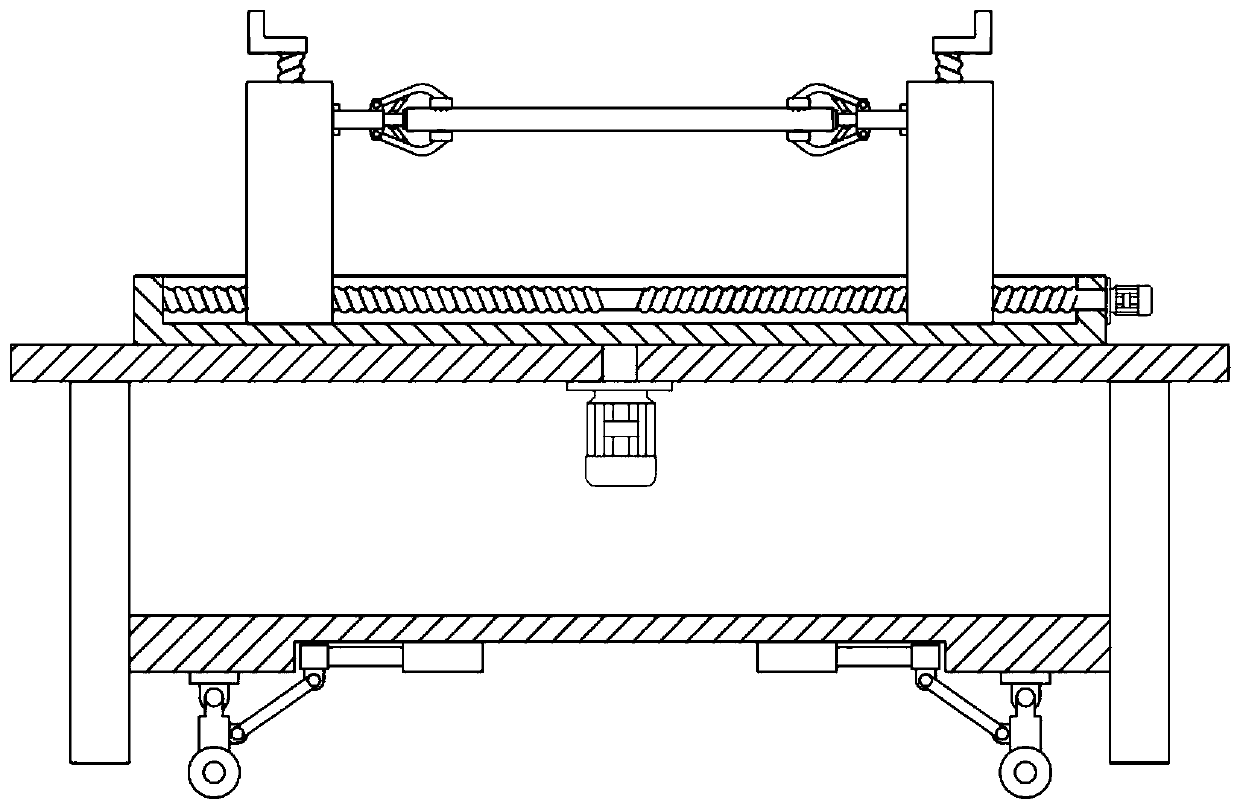

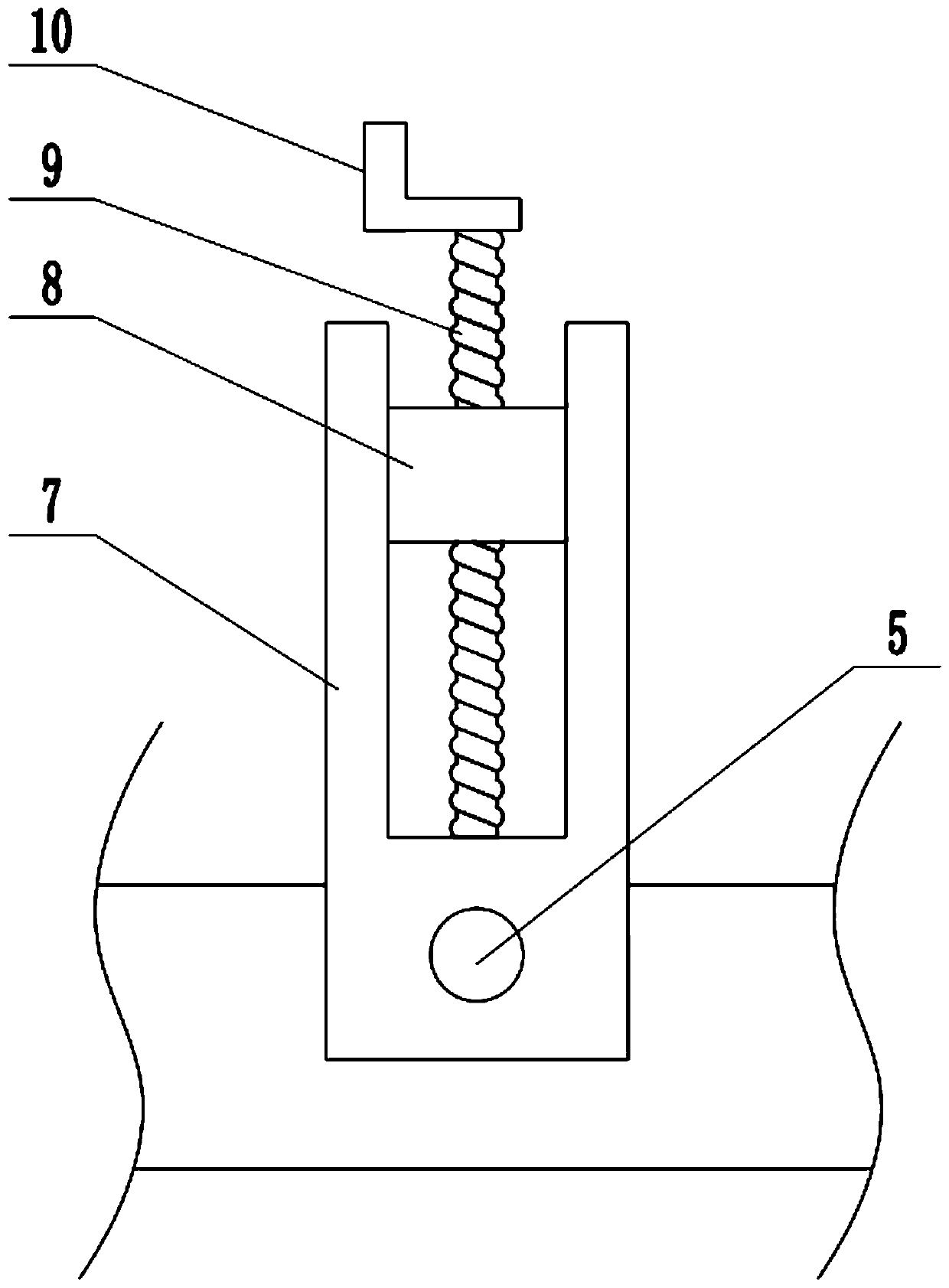

[0023] see Figure 1-5 , in an embodiment of the present invention, a mobile clamping workbench for round steel processing includes a table top 1, a rotary table 2, a two-way screw rod 5 and a movable support 7, and the upper surface of the table top 1 is rotatably connected with a rotary table 2 , the bottom of the table top 1 is fixedly connected with a rotary motor 3, and the shaft end of the rotary motor 3 passes through the table top 1 and is fixedly connected with the bottom of the rotary table 2, and the rotary motor 3 is started to drive the rotary table 2 to rotate, and the upper surface of the rotary table 2 A chute 4 is provided, and a two-way screw rod 5 is installed inside the chute 4, and the left and right ends of the two-way screw rod 5 are respectively connected to the side wall of the chute 4 in rotation, and the outer wall of the rotary table 2 is fixedly connected with a clamping motor 6 , the shaft extension end of the clamping motor 6 is fixedly connected...

Embodiment 2

[0027] On the basis of Embodiment 1, the bottom of the table top 1 is fixedly connected with a support plate 20. There are two support plates 20 arranged symmetrically on the left and right. Fixedly connected, the lower surface of the fixed plate 21 is equipped with a moving mechanism, the moving mechanism includes a telescopic mechanism 22, a slide block 23, a support rod 24, a movable rod 25 and a universal wheel 26, and the lower surface of the fixed plate 21 is fixedly connected with a telescopic mechanism 22 , the telescopic mechanism 22 is an electrohydraulic telescopic cylinder, the extended end of the telescopic mechanism 22 is fixedly connected with a slider 23, the slider 23 is slidably connected with the bottom of the fixed plate 21, the lower surface of the slider 23 is hinged with a movable rod 25, and the fixed plate The lower surface of 21 is hinged with support rod 24, and the lower end of support rod 24 is equipped with universal wheel 26, and the lower end of ...

Embodiment 1、 Embodiment 2

[0028] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: place the end of the round steel to be processed in the clamping mechanism 11, start the clamping motor 6, drive the two-way screw mandrel 5 to rotate, and then drive two The movable bracket 7 moves towards each other, so that the end of the round steel contacts the fixed block 15, pushes the slide bar 14 to move to the inside of the casing 12, and uses the connecting rod 16 to drive the jaws 13 to rotate, and the two jaws 13 are closed together. The clamping plate 17 clamps the end of the round steel to complete the clamping action. The clamping speed is fast, which greatly improves the work efficiency. When the rotating motor 3 is started, the rotary table 2 can be driven to rotate, thereby adjusting the position of the round steel, which is convenient for processing and turning. Shake the handle 10 to drive the lifting block 8 to move up and down. The height of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com