Film stretching device and manufacturing method for stretch film

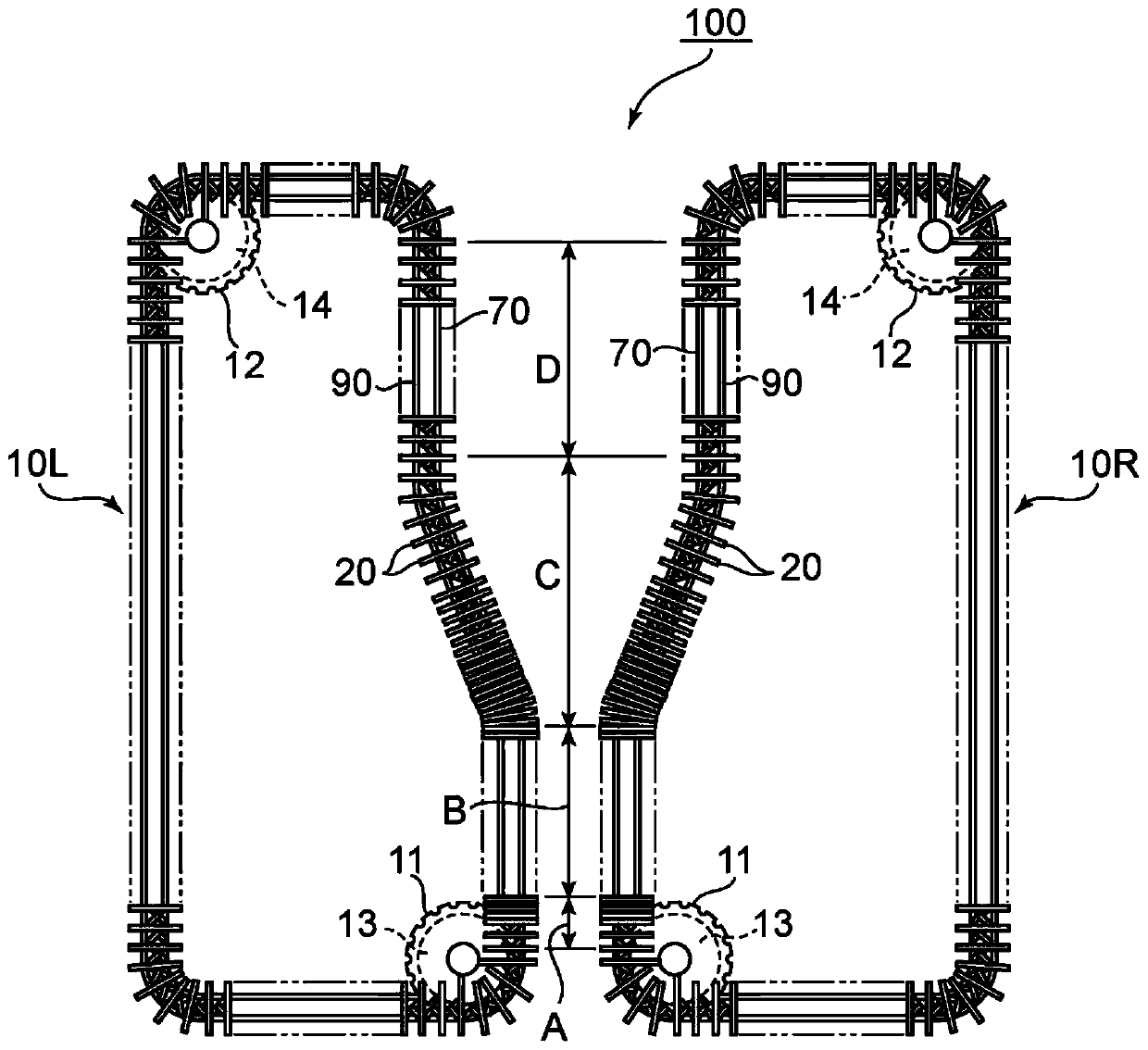

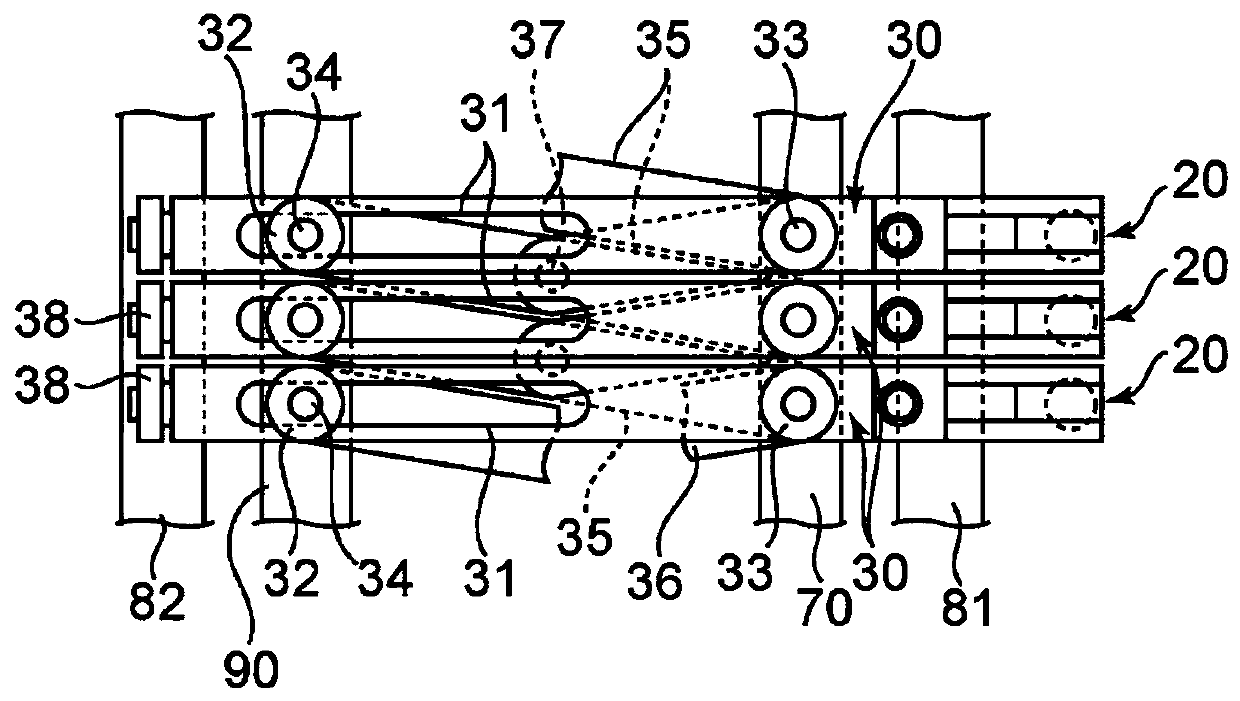

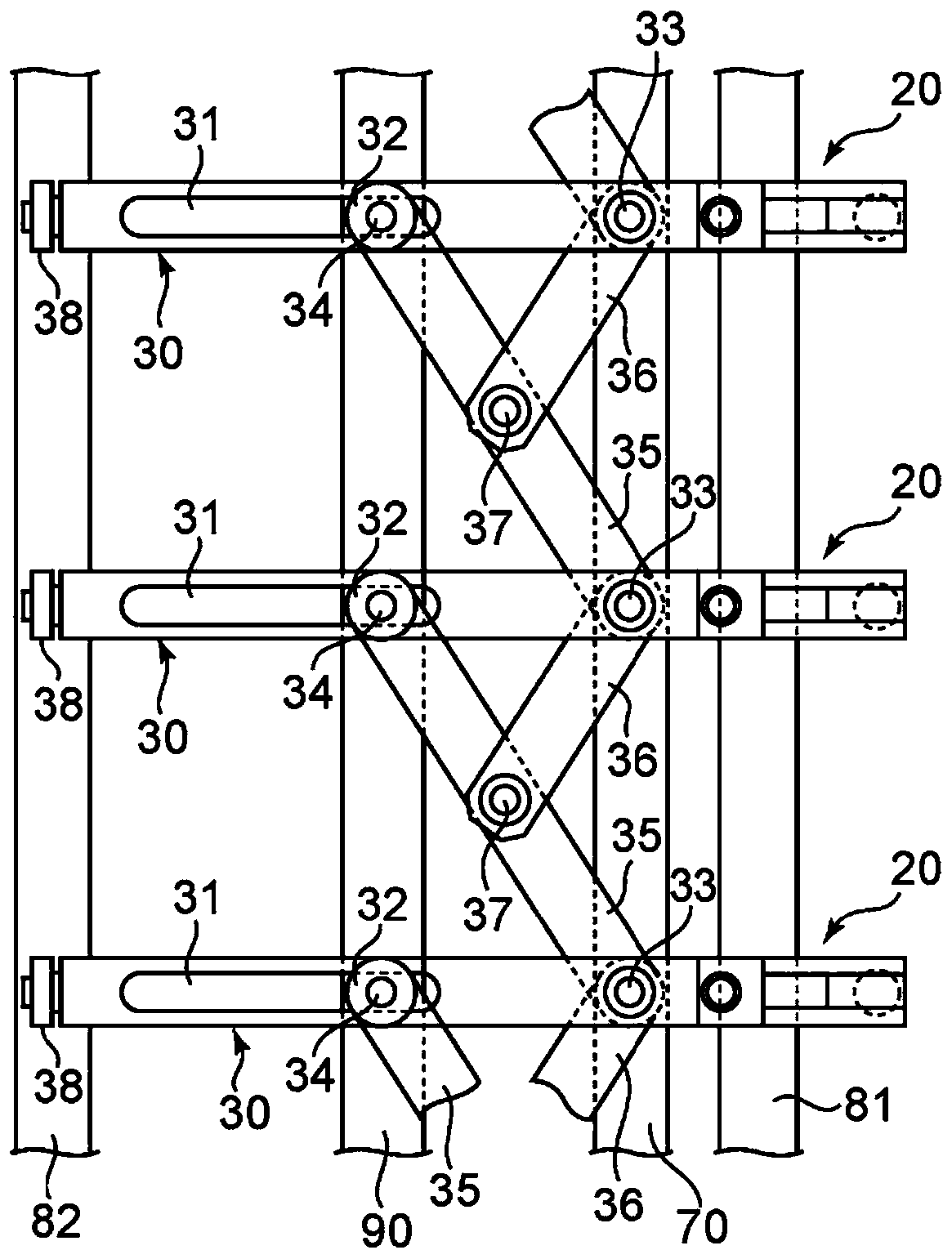

A technology of stretching device and manufacturing method, which is applied in the field of film stretching device and stretched film manufacturing, can solve problems such as film fracture, achieve the effect of suppressing fracture and realizing large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] (Production of polyester carbonate resin film)

[0150] Polymerization was performed using a batch polymerization apparatus consisting of two vertical reactors each including a stirring blade and a reflux cooler controlled at 100°C. 29.60 parts by mass (0.046mol) of bis(9-(2-phenoxycarbonyl ethyl)fluoren-9-yl)methane, 29.21 parts by mass (0.200mol) of ISB, 42.28 parts by mass of (0.139mol) of SPG, 63.77 mass parts (0.298mol) of DPC, and 1.19×10 -2 Parts by mass (6.78×10 -5 mol) of calcium acetate monohydrate. After depressurizing and nitrogen-substituting the inside of the reactor, it was heated with a heating medium, and stirring was started when the internal temperature reached 100°C. 40 minutes after the start of temperature rise, the internal temperature was brought to 220°C, and the pressure was reduced while controlling to maintain the temperature, and the pressure in the reactor was set to 13.3 kPa within 90 minutes after the temperature reached 220°C. Phenol...

Embodiment 2

[0161] Use a rectangular jig with a lower surface of the upper holding member of 45mm x 25mm, and if Figure 13 As shown in (b), except that the distance (D) from the edge of the film to the clamping position was 25 mm, the film was held by a clamp, and the same as in Example 1, until the film was broken. The diagonal stretch ratio at breakage was calculated, and a film just before breaking was produced based on the diagonal stretch ratio at breakage, and the amount of neck-in at the time of breakage was obtained. The holding length (L) and holding amount (W) are 45mm and 25mm, respectively.

Embodiment 3

[0163] Use a rectangular jig with the lower surface of the upper holding member of 45mm x 20mm in size, and if Figure 13 (b) shows that the distance (D) from the edge of the film to the clamping position is 20 mm, except that the film is held by a jig, and the film is tilted in the same manner as in Example 1 until the film breaks. Stretching was carried out to calculate the oblique draw ratio at breakage, and a film just before breakage was produced based on the diagonal draw ratio at breakage, and the amount of neck-in just before breakage was obtained. The holding length (L) and holding amount (W) are 45mm and 20mm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com