A boat loading and palletizing device

A palletizing device and charging technology, which is applied to automatic weighing and palletizing workstations for powders, automatic weighing and automatic palletizing of boats, and can solve the problems of high labor intensity, large weighing errors, and serious environmental pollution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

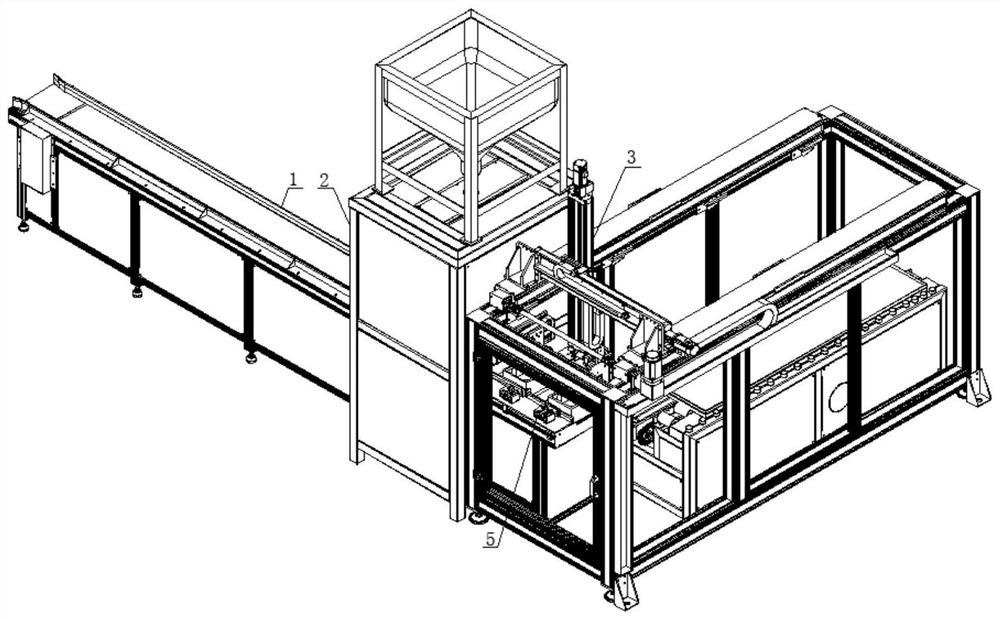

[0035] Such as figure 1 As shown, the present embodiment provides a boat loading and palletizing device, including a conveying mechanism 1, a charging mechanism 12, a feeding mechanism 4, a positioning mechanism 5, a palletizing mechanism 3, and a controller;

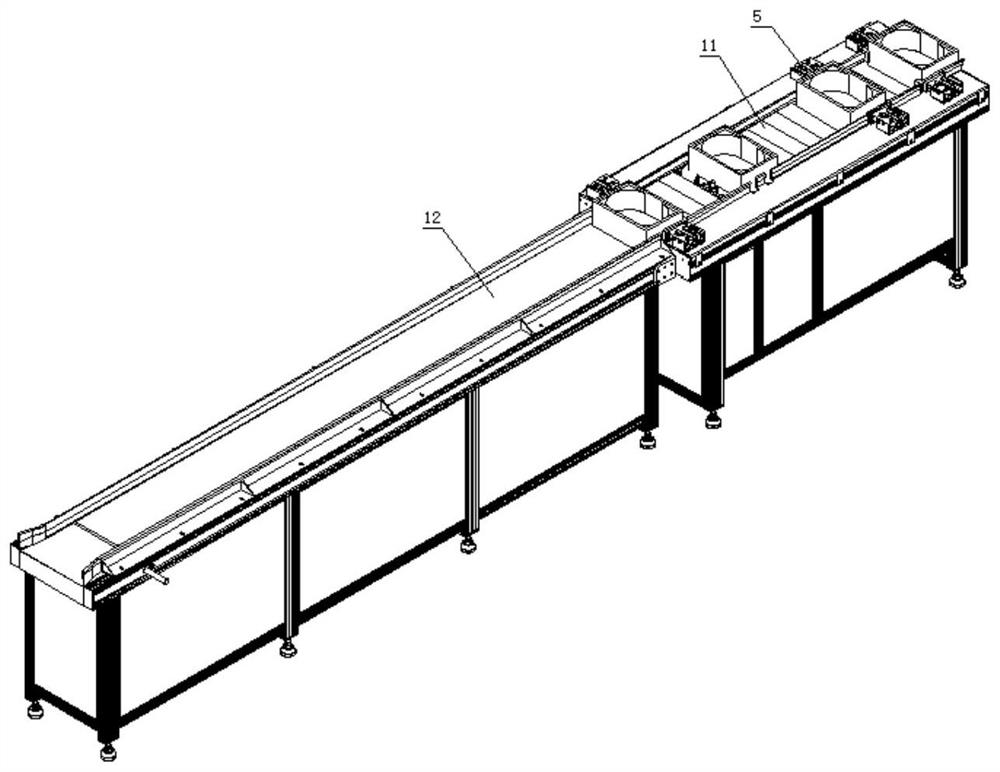

[0036] Such as figure 2 As shown, the transmission mechanism 1 includes a roller conveyor line 11 and a belt conveyor arranged at the input end of the roller conveyor line 11, and the conveyor belt 12 of the belt conveyor is docked with the roller conveyor line 11 to form a transmission line; as image 3 As shown, the idler conveyor line 11 passes through the charging mechanism 12;

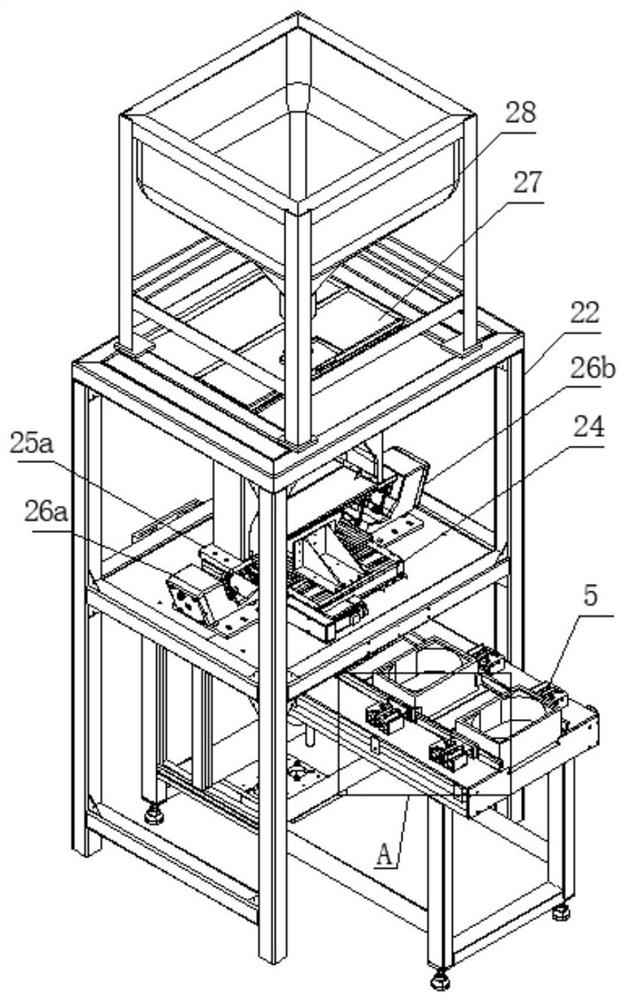

[0037] Such as image 3 , 4 As shown, the charging mechanism 12 includes a weighing platform 21, a frame 22, and a blanking bin 23, a swing module 24, a vibrator, a tray, a sub-hopper 2827, and a hopper 28 arranged on the frame 22; the weighing platform 21 is provided with a weighing sensor, and the lower end of the weighing platform 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com