Tubular aeration tank type high-temperature aerobic composting system

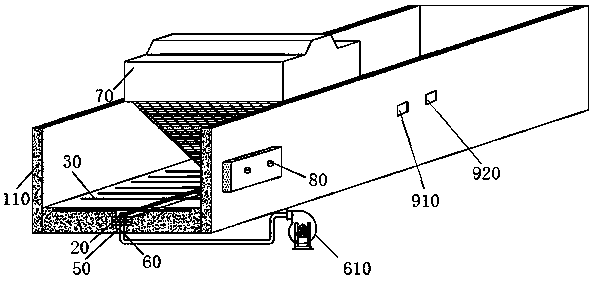

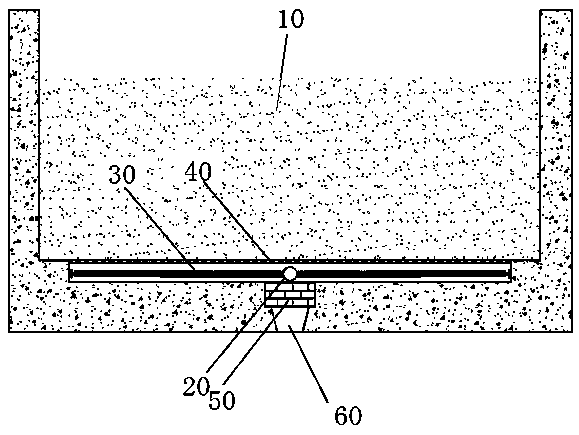

An aerobic composting and aeration tank technology, which is applied to organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve problems such as uneven aeration, disorderly discharge of wastewater, and low fermentation efficiency, so as to improve oxygen mass transfer efficiency, Uniform gas distribution and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

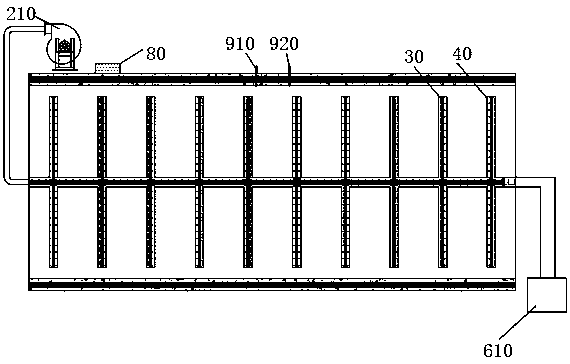

[0036] Embodiment 2, on the basis of the above embodiments, in this embodiment, a temperature sensor 910 and an oxygen concentration sensor 920 are arranged on the side of the fermenter and are connected to the controller 80, and the aeration fan is connected to the controller 80 . The temperature sensor 910 and the oxygen concentration sensor 9200 are arranged in the middle of the fermentation tank wall 110, and the controller 80 can obtain the data of the temperature sensor 910 and the oxygen concentration sensor 920, and automatically adjust the operation of the system equipment according to the required temperature and oxygen concentration; The aeration fan 210 is connected to the PLC automatic controller 80, which can realize the automatic operation of the aeration fan 210 according to needs, and effectively reduce energy consumption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com