A kind of controllable degradation recovery method of polyurethane

A recycling method and polyurethane technology, applied in the direction of plastic recycling, recycling technology, chemical instruments and methods, etc., can solve the problems of difficult separation of mixture monomers, harsh reaction conditions, large environmental pollution, etc., and achieve high recycling value and high reaction efficiency. The effect of moderate temperature and easy availability of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

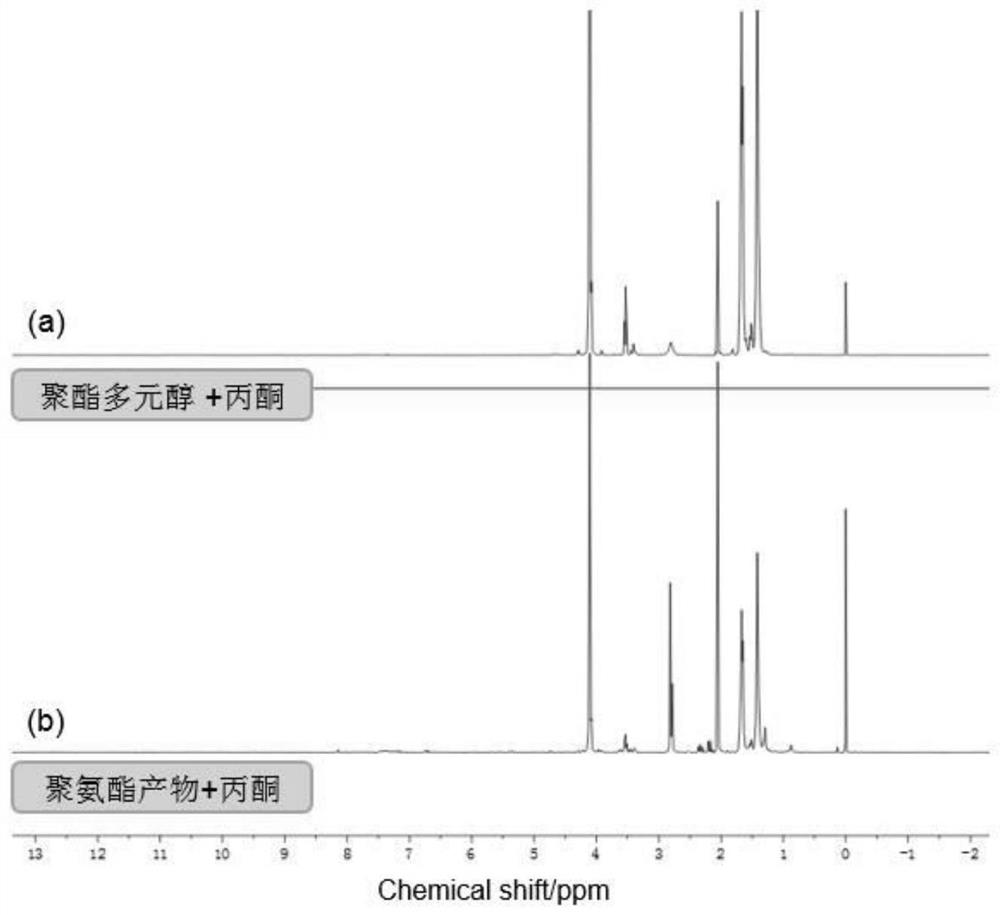

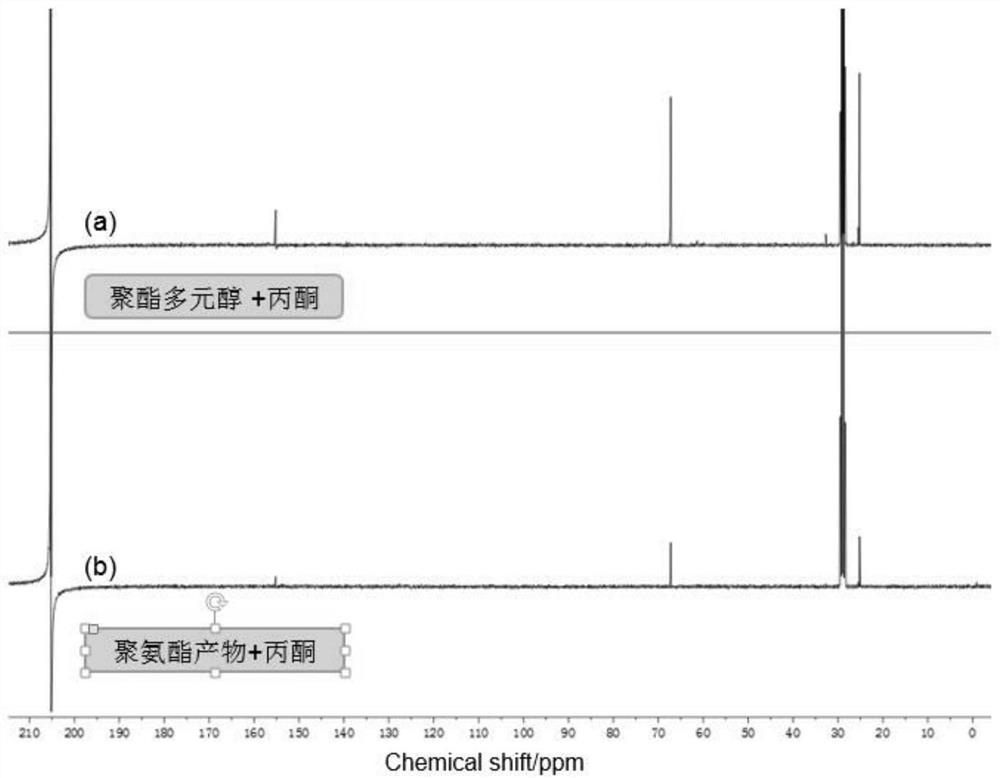

Embodiment 1

[0024] Choline chloride and ethylene glycol are mixed to form a transparent and uniform deep eutectic solvent 1. 1 gram of polyurethane is placed in a reaction kettle, 5 grams of deep eutectic solvent 1 is added, and the reaction kettle is sealed and heated at 100°C for 10 hours. Add 15 grams of water to the degradation product after the reaction finishes, filter after fully stirring, obtain filtrate and filter cake, reclaim after filtrate rotary steaming and obtain deep eutectic solvent-and water; Add 3 grams of acetone to make it dissolve in the filter cake, then The acetone was distilled off under reduced pressure to obtain a solid. Add 0.5 gram of hydrochloric acid to the solid, stir and let it stand, then add 3 grams of water, filter after stirring, wash the filter cake with water for 2 times and dry to obtain polymer polyol; add sodium hydroxide solution to the filtrate to adjust the pH of the filtrate to 7 , and then filtered to obtain anilines. Cycle 6 to use recovere...

Embodiment 2

[0026] Tetramethylammonium chloride and oxalic acid are mixed to form a transparent and uniform deep eutectic solvent 2, 1 gram of polyurethane is placed in a reaction kettle, 8 grams of deep eutectic solvent 2 is added, and the reaction kettle is sealed and heated at 120°C for 8 Hour. Add 24 grams of water to the degradation product after the reaction finishes, filter after fully stirring, obtain filtrate and filter cake, reclaim after filtrate rotary steaming and obtain deep eutectic solvent two and water; Add 5 grams of tetrahydrofuran to make it dissolve in the filter cake, then Tetrahydrofuran was distilled off under reduced pressure to obtain a solid. Add 1 gram of sulfuric acid to the solid, stir and let stand, then add 5 grams of water, filter after stirring, wash the filter cake with water for 3 times and dry to obtain polymer polyol; add potassium hydroxide solution to the filtrate to adjust the pH of the filtrate to 7 , and then filtered to obtain anilines. Cycle ...

Embodiment 3

[0028] Tetraphenylphosphonium bromide and ethylenediamine are mixed to form a transparent and uniform deep eutectic solvent. 3. Put 1 gram of polyurethane in the reaction kettle, add 10 grams of deep eutectic solvent 3, seal the reaction kettle and heat it at 140°C for reaction 6 Hour. Add 30 grams of water to the degraded product after the reaction finishes, filter after fully stirring to obtain the filtrate and filter cake, reclaim after the filtrate rotary steaming to obtain the deep eutectic solvent Sanhe water; add 4 grams of tetrahydrofuran to make it dissolve in the filter cake, and then Tetrahydrofuran was distilled off under reduced pressure to obtain a solid. Add 2 grams of sulfuric acid to the solid, stir and let stand, then add 4 grams of water, filter after stirring, wash the filter cake with water for 3 times and dry to obtain polymer polyol; add sodium hydroxide solution to the filtrate to adjust the pH of the filtrate to 7 , and then filtered to obtain aniline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com