Comprehensive plugging and repairing method for elevator shaft leakage

A technology for elevator shafts and construction methods, applied in building maintenance, infrastructure engineering, protection devices, etc., can solve problems that affect elevator operation safety, people's normal travel, and elevator shaft leakage control is not thorough, so as to achieve the effect of lifting and eliminate hazards Events, the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The comprehensive plugging and repairing method for elevator shaft leakage is characterized in that it comprises the following steps:

[0032] (1) Find water seepage points: In order to facilitate the search for water seepage points, remove the cement mortar plaster layer and waterproof material layer in the elevator shaft before the plugging construction;

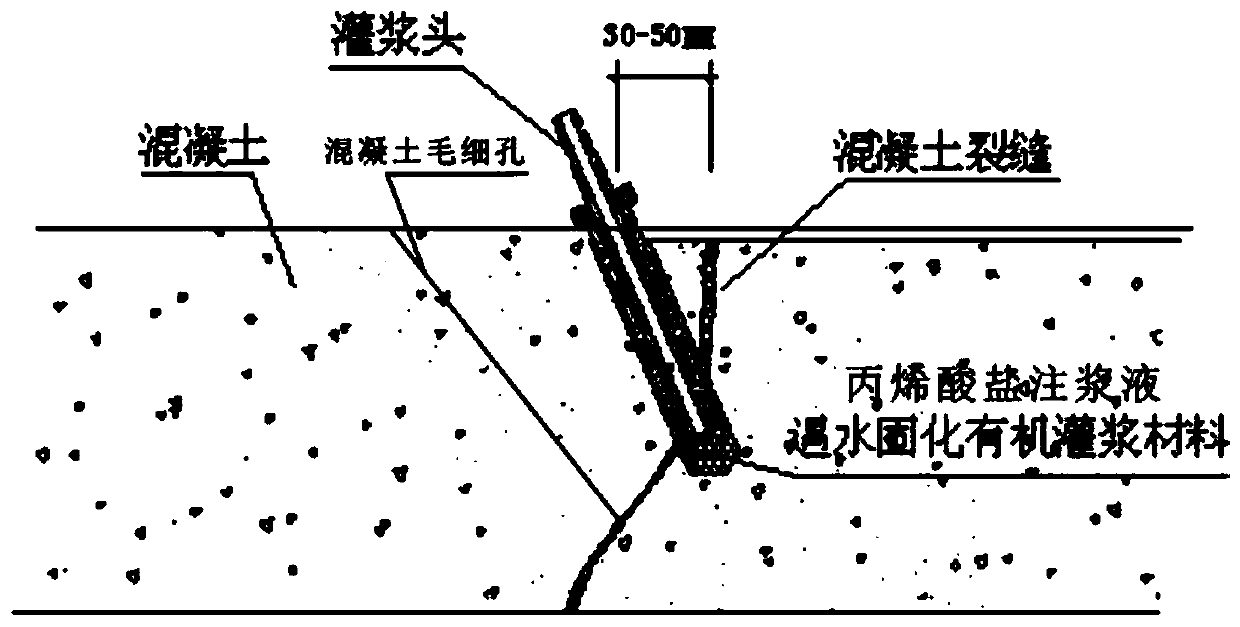

[0033] (2) Carry out plugging construction treatment according to the characteristics of the seepage point. If the characteristic of the seepage point is point leakage, then use the direct plugging method for plugging. The material used in the direct plugging method is water-tight; if the characteristic of the seepage point is If there is no line leakage or surface leakage, the pressure grouting method is used for plugging, and the materials used in the pressure grouting method are water-soluble polyurethane and acrylate;

[0034] (3) After the plugging construction treatment, make a waterproof layer on the back wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com