Rotary excavator slag collection and lifting device

A technology of rotary excavator and slag, which is applied in earth-moving drilling, wellbore/well components, etc., can solve problems such as affecting the continuous drilling of drilling tools, achieve high slag collection efficiency, improve drilling efficiency, and high automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

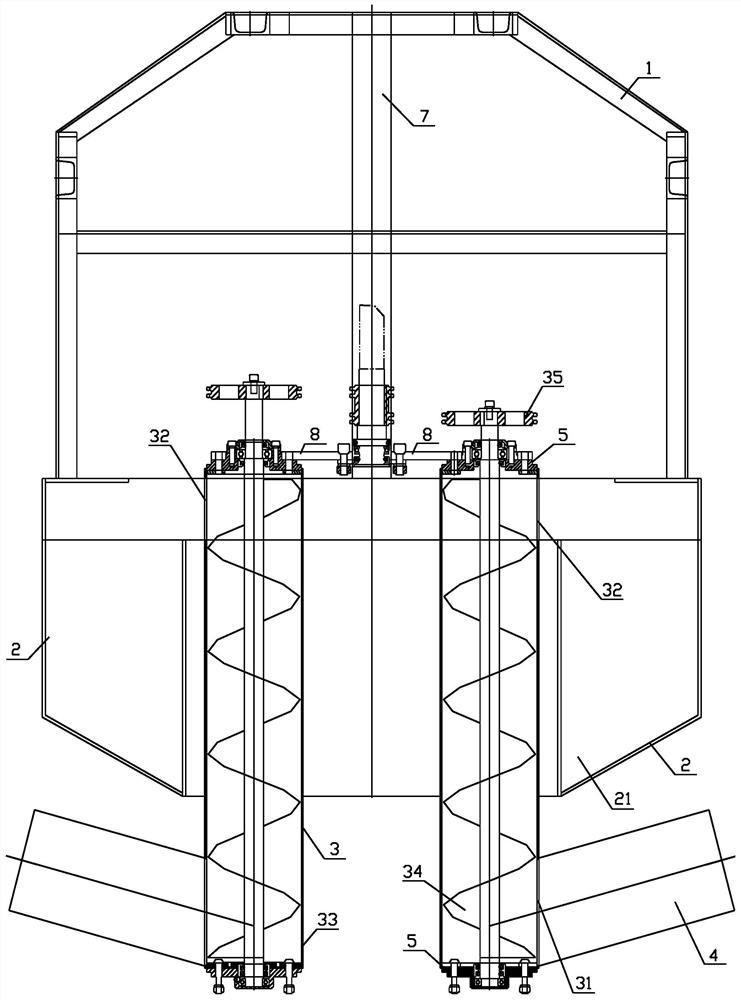

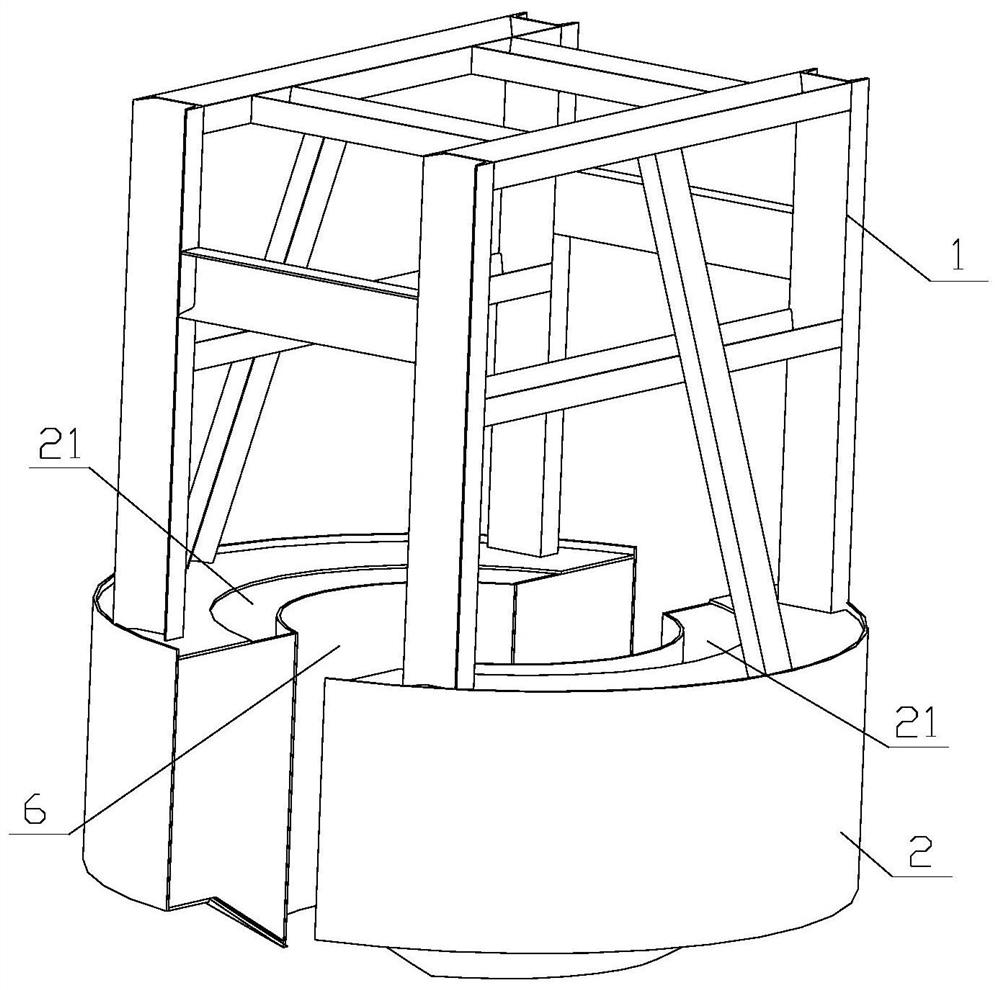

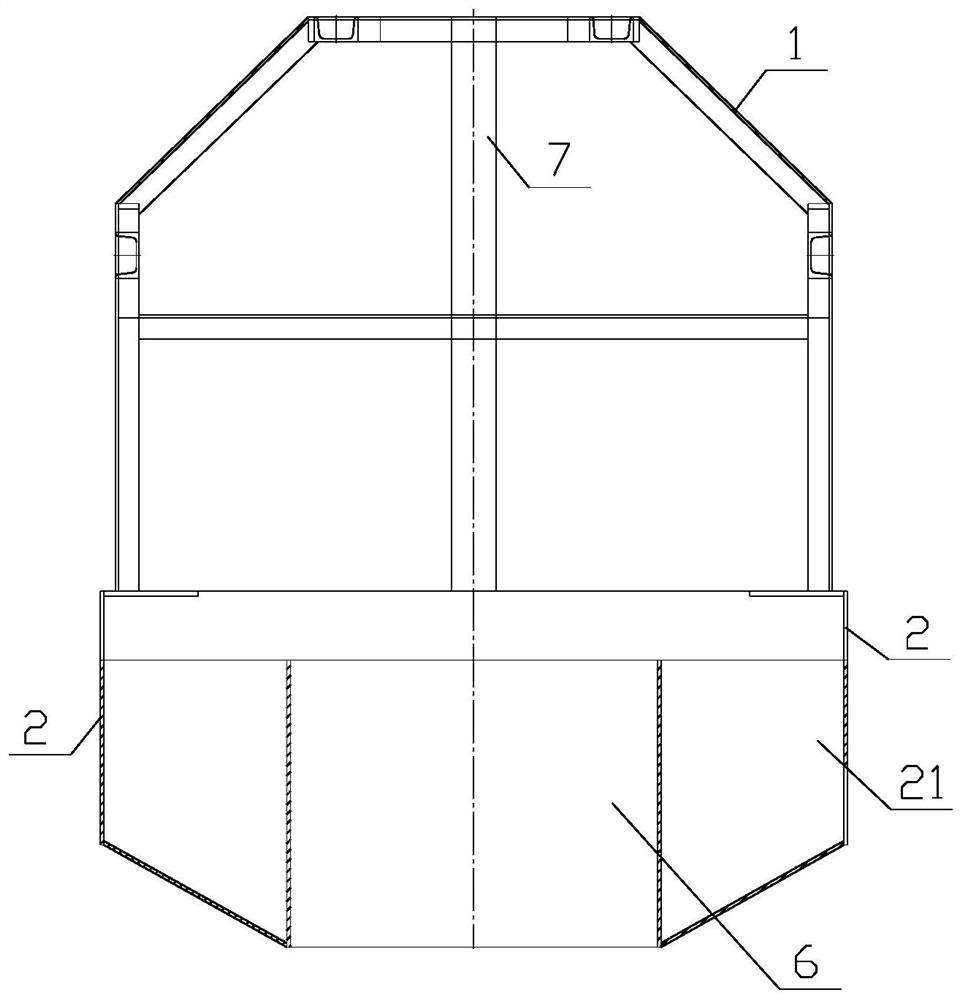

[0034] Such as Figure 1-3 As shown, the muck collection and lifting device for rotary excavator of the present invention includes a frame 1, a hopper 2 and a muck lifting assembly 3, the frame 1 is connected to the hopper 2, and the hopper 2 and the muck lifting assembly 3 are several One, and the hopper 2 and the slag lifting assembly 3 correspond one by one, the bottom of the slag lifting assembly 3 is provided with a feed port 31, and the feed port 31 is connected with a slag collecting mechanism 4, and the top is provided with a slag collection mechanism 4 communicated with the hopper 2 The discharge port 32, several muck lifting assemblies 3 are connected with a revolution driving mechanism, the muck lifting assemblies 3 rotate around the centerline of the frame 1 under the drive of the revolution driving mechanism, and the muck collecting mechanism 4 collects muck during the rotation process .

[0035] The muck lifting assembly 3 includes a transmission cylinder 33 and...

Embodiment 2

[0043] Such as Figure 1-3 As shown, the muck collection and lifting device for rotary excavator of the present invention includes a frame 1, a hopper 2 and a muck lifting assembly 3, the frame 1 is connected to the hopper 2, and the hopper 2 and the muck lifting assembly 3 are several One, and the hopper 2 and the slag lifting assembly 3 correspond one by one, the bottom of the slag lifting assembly 3 is provided with a feed port 31, and the feed port 31 is connected with a slag collecting mechanism 4, and the top is provided with a slag collection mechanism 4 communicated with the hopper 2 The discharge port 32, several muck lifting assemblies 3 are connected with a revolution driving mechanism, the muck lifting assemblies 3 rotate around the centerline of the frame 1 under the drive of the revolution driving mechanism, and the muck collecting mechanism 4 collects muck during the rotation process .

[0044] The muck lifting assembly 3 includes a transmission cylinder 33 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com