New energy automobile motor test board

A new energy vehicle and motor testing technology, applied in the direction of motor generator testing, etc., can solve problems such as drive motor output shaft jumping, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

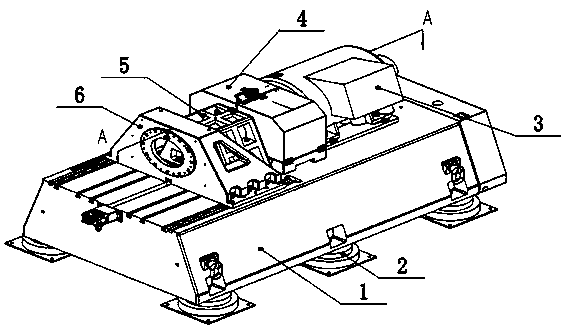

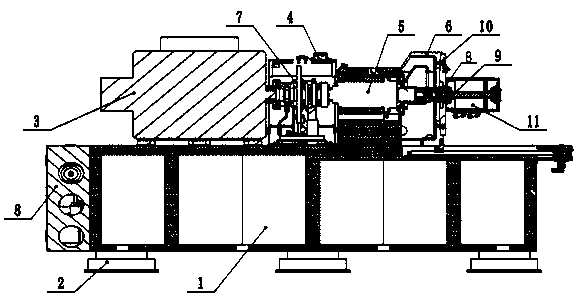

[0042] Example 1: see figure 1 with figure 2 , New energy vehicle motor test bench, including workbench 1 and valve box 8 set on workbench 1, dynamometer 3 set on workbench 1, dynamometer 3 is provided with an output shaft inside, and the output shaft is connected There is a motor shaft 9 to be tested, and the motor shaft 9 is connected with a new energy motor 11; there is a drive device for driving the dynamometer 3 and the new energy motor 11. When the drive device drives the dynamometer 3, the new energy motor 11 generates power. When the device drives the new energy motor 11, the dynamometer 3 generates electricity; it also includes a locked-rotor mechanism 7 that prevents the output shaft from rotating. A shield 4 is provided outside the locked-rotor mechanism 7 to prevent the locked-rotor mechanism 7 from getting wet. One side of the locked-rotor mechanism 7 is coaxially connected with the dynamometer 3, and the other side of the locked-rotor mechanism 7 is connected with...

Embodiment 2

[0046] Example 2: see Figure 4 The basic structure of the second embodiment is the same as that of the first embodiment. The difference is that the locked-rotor mechanism 7 includes a hydraulic device and a locked-rotor disk 17, and the locked-rotor disk 17 is embedded with an adapter disk 18 fixed on the output shaft, and the adapter disk 18 is used to test the torque of the output shaft. The two sides of the locked turntable 17 are respectively provided with brakes 16 for clamping both sides of the locked turntable 17, and the brakes 16 are driven by hydraulic devices. A hydraulic pipe 19 is provided on the hydraulic device, and the hydraulic pipe 19 is connected to the input end of the brake 16. The hydraulic pipe 19 transmits a pressure source to the brake 16 so that the brake 16 locks the blocking disk 17.

[0047] Before starting the locked-rotor test, the brake 16 is driven by a hydraulic device. Then, the brake 16 locks the locked-rotor disc 17 and starts the locked-roto...

Embodiment 3

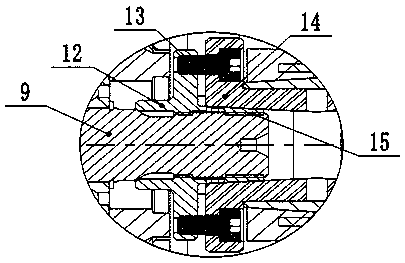

[0048] Example 3: See image 3 with Figure 5 The basic structure of the third embodiment is the same as that of the first embodiment, the difference is that the spline expansion sleeve structure includes an inner ring 12 and an outer ring 14 arranged from the inside to the outside. The inner wall of the inner ring 12 and the outer wall of the spline adapter shaft For spline connection, the outer ring 14 is arranged in the bearing housing 5, and a coupling plate 10 is arranged in the bearing housing 5 for fixing the output shaft. The inner ring 12 includes an inner ring flange 20 and one side thereof is fixedly connected with an inner ring cone 22. The inner ring flange 20 is provided with a number of inner ring mounting holes; the outer ring 14 includes an outer ring flange and one side fixed The outer ring cone is connected, and the outer ring flange is provided with a number of outer ring mounting holes; the inner ring mounting holes and outer ring mounting holes are both th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com