Spray cooling type cold plate

A spray cooling and cold plate technology, which is applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of insufficient volume, adaptability and versatility of coverage, and inability to meet the heat dissipation requirements of thermal control systems. Achieve the effect of large spray coverage, small space and reasonable liquid coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

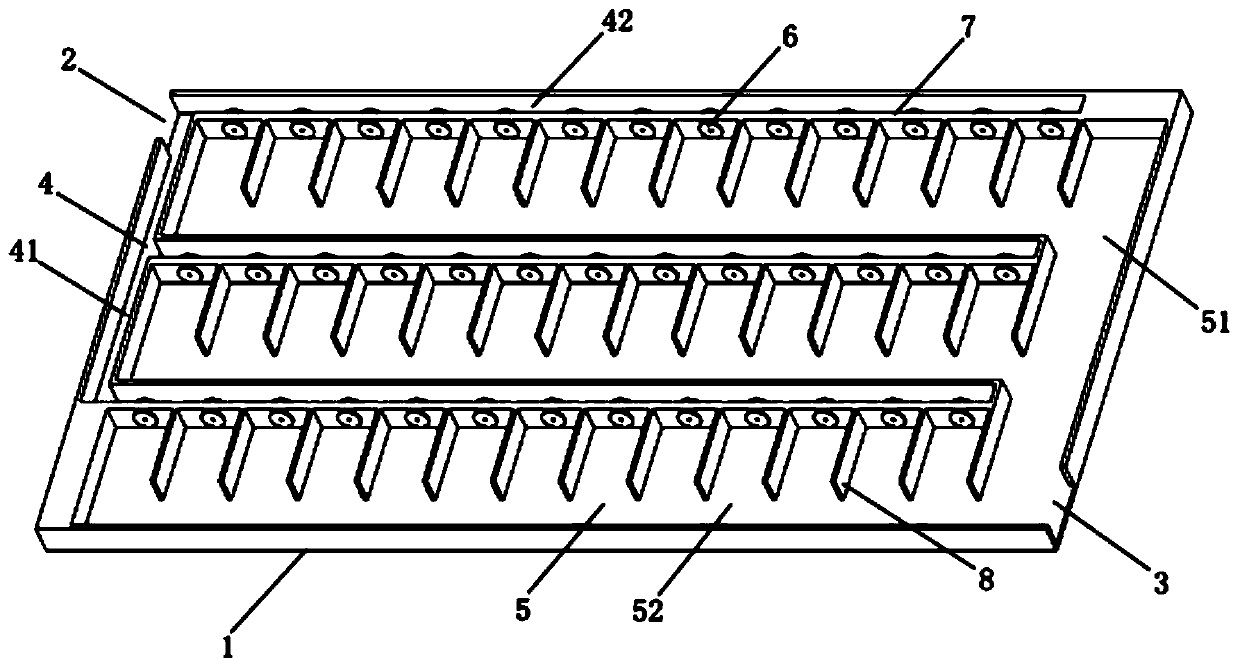

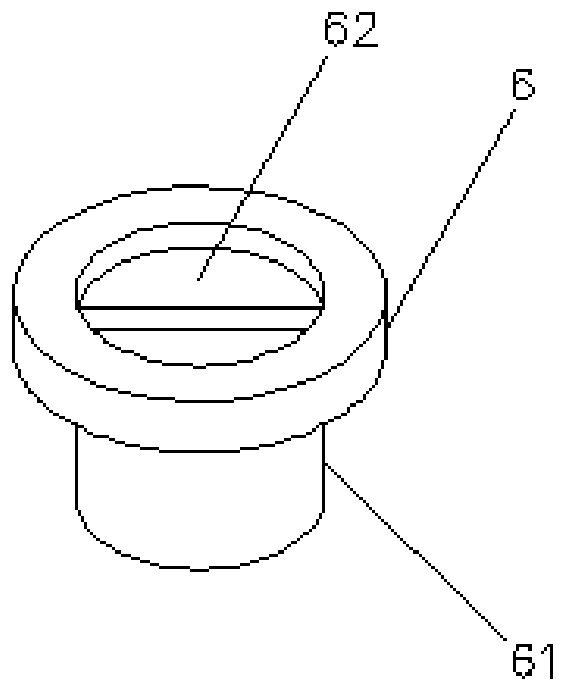

[0031] like Figure 1-3 As shown, the spray-cooled cold plate includes a cold plate shell 1 , a liquid inlet 2 , a liquid discharge 3 , a liquid separation chamber 4 , an atomization chamber 5 , an atomization nozzle 6 , a separator 7 , and fins 8 .

[0032] The cold plate shell 1 is a cuboid hollow thin plate shell with an external dimension of 300mm×150mm×10mm, and its cooling surface is the liquid coverage area on two surfaces of 300mm×150mm; Liquid port 2, liquid discharge port 3, the inner cavity of the cold plate housing 1 is divided into a liquid chamber 4 and an atomization chamber 5 by a partition 7, and the partition 7 is a whole and is connected with the side plate of the cold plate housing 1. One structure.

[0033] The liquid separation chamber 4 includes a liquid inlet flow channel 41 and a liquid separation flow channel 42; the linear liquid inlet flow channel 41 is located on the side of the liquid inlet 2 in the cold plate housing 1 and is parallel to the sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap