Display substrate and manufacturing method thereof

A technology for display substrates and substrates, used in semiconductor/solid-state device manufacturing, instruments, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

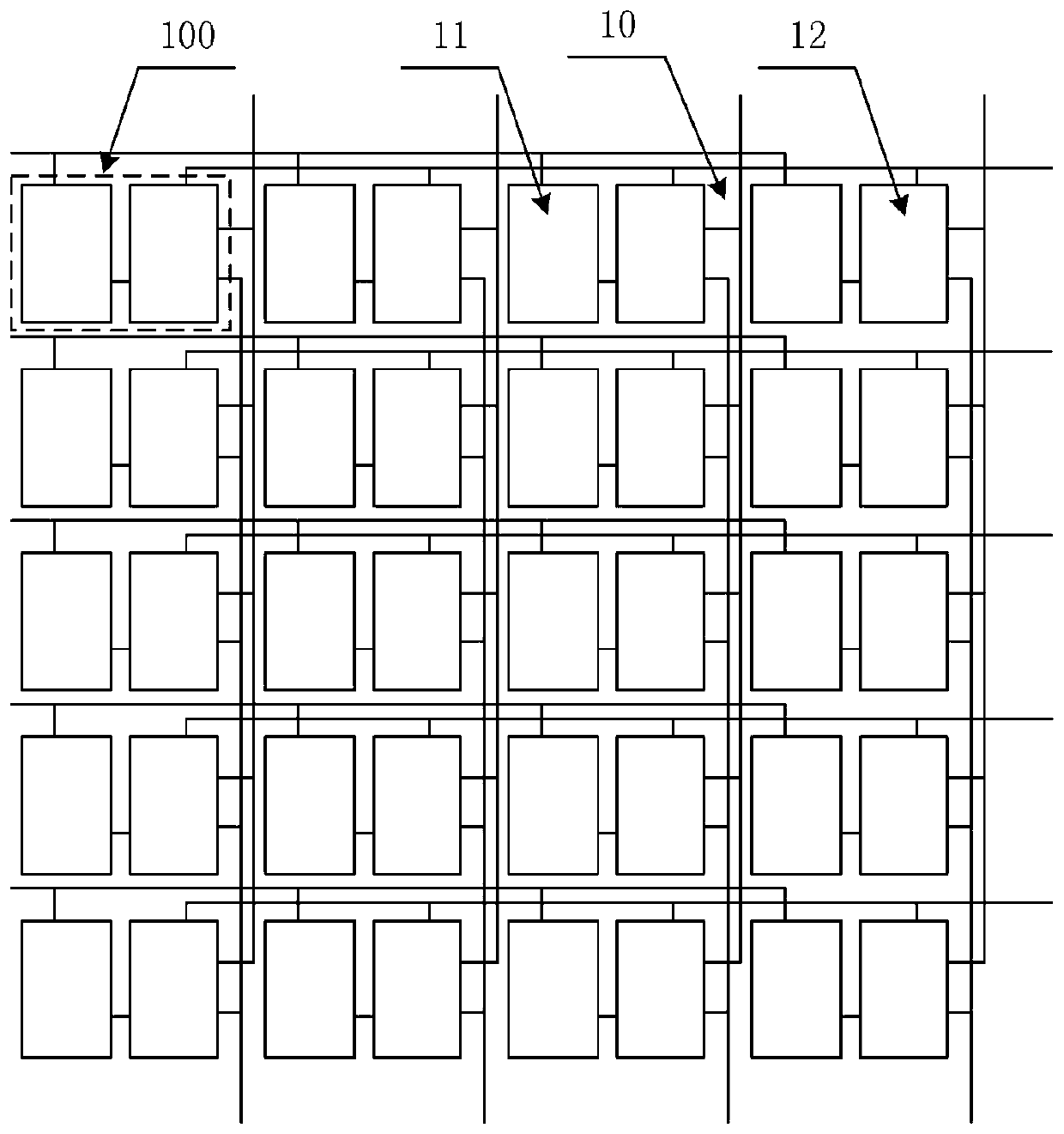

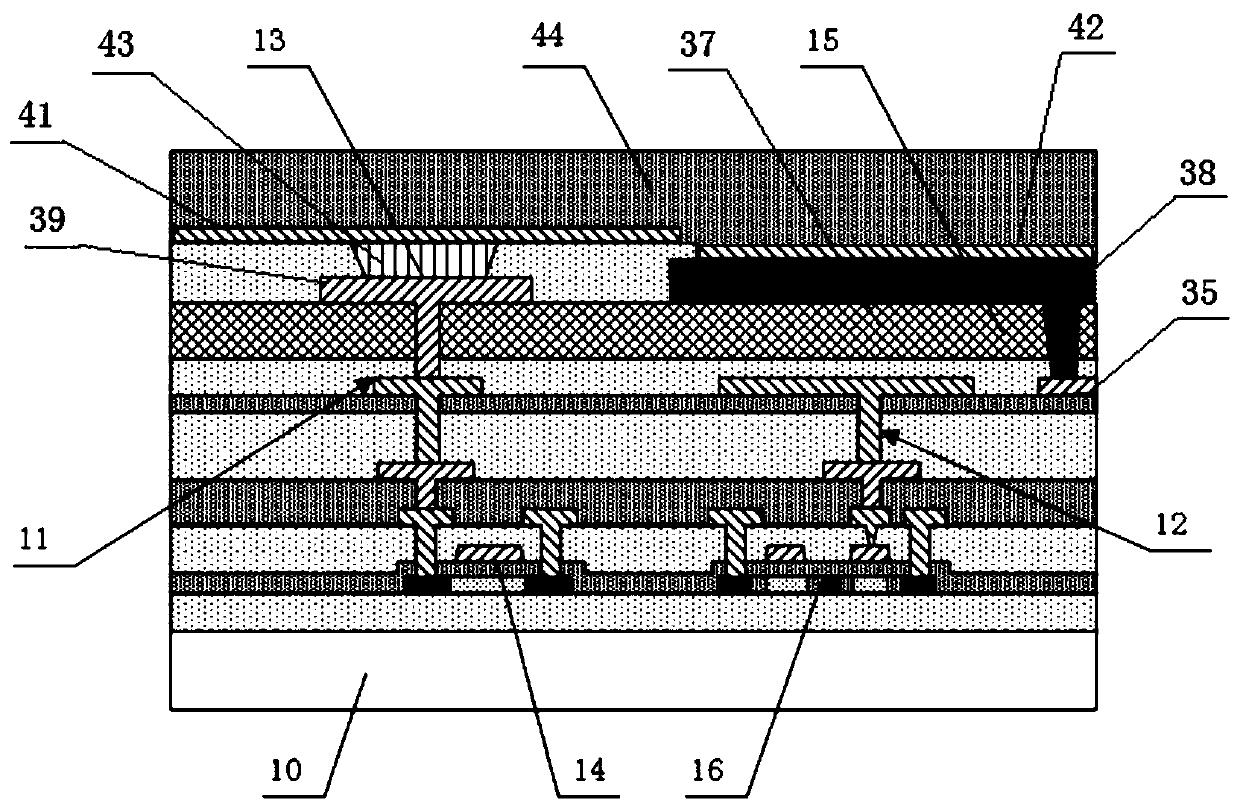

[0069] The display substrate of this embodiment is prepared by a complementary metal-oxide-semiconductor (Complementary MetalOxide Semiconductor, CMOS) process. Such as figure 2 As shown, the embodiment of the present invention shows that the display substrate includes a base 10, and a light emitting structure layer 11 and a fingerprint recognition structure layer 12 formed on the base 10. The light emitting structure layer 11 includes a light emitting unit 13 and a light emitting driving circuit 14. The light emitting unit 13 is used for The display light is emitted, and the light-emitting drive circuit 14 is used to control and drive the light-emitting unit 13 . The fingerprint identification structure layer 12 includes a fingerprint identification sensor 15 and a processing circuit 16. The fingerprint identification sensor 15 is used to form a fingerprint electrical signal, and the processing circuit 16 is used to receive the fingerprint electrical signal from the fingerpr...

no. 2 example

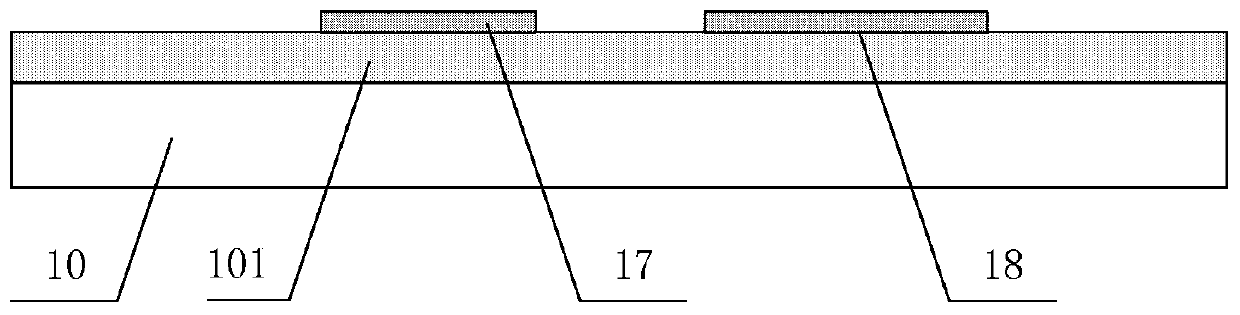

[0095] Figure 13 A schematic diagram showing the structure of the second embodiment of the substrate according to the present invention shows a structure prepared by using an N-channel metal-oxide-semiconductor (Negative Channel Metal Oxide Semiconductor, NMOS) process.

[0096] Such as Figure 13 As shown, the display substrate of this embodiment includes a base 10 , and a light emitting structure layer 11 and a fingerprint recognition structure layer 12 formed on the base 10 . The light-emitting structure layer 11 includes a light-emitting unit and a light-emitting drive circuit. The fingerprint recognition structure layer 12 includes a fingerprint recognition sensor for forming fingerprint electrical signals. The fingerprint recognition sensor includes a piezoelectric film layer, and the piezoelectric film layer is located between the light-emitting unit and the light-emitting drive circuit. and cover the pixel unit, the light emitting unit penetrates through the piezoele...

no. 3 example

[0100] Figure 14 A schematic diagram showing the structure of the third embodiment of the substrate according to the present invention shows a structure prepared by using a P-channel metal-oxide-semiconductor (Positive Channel Metal Oxide Semiconductor, PMOS) process.

[0101] Such as Figure 14 As shown, the display substrate of this embodiment includes a base 10 , and a light emitting structure layer 11 and a fingerprint recognition structure layer 12 on the base 10 . The light-emitting structure layer 11 includes a light-emitting unit and a light-emitting drive circuit. The fingerprint recognition structure layer 12 includes a fingerprint recognition sensor for forming fingerprint electrical signals. The fingerprint recognition sensor includes a piezoelectric film layer, and the piezoelectric film layer is located between the light-emitting unit and the light-emitting drive circuit. and cover the pixel unit, the light emitting unit penetrates through the piezoelectric thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com