Thin-film blow-molding machine capable of realizing replacement of mold head

A film blow molding and blow molding machine technology, applied in the field of film processing equipment, can solve problems such as affecting product quality, untimely adjustment, and low accuracy, and achieve the effects of stable product quality, improved product quality, and timeliness stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

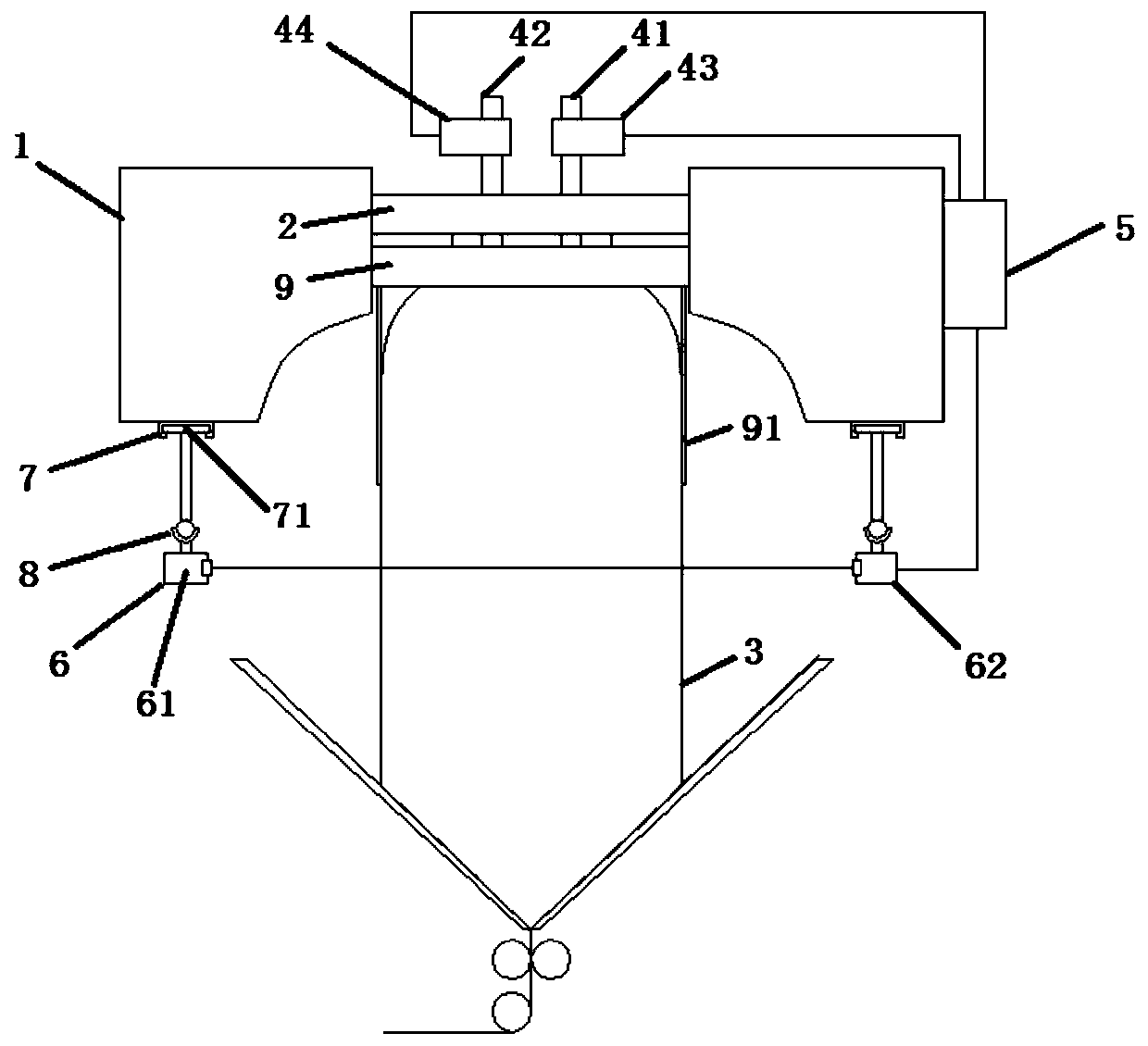

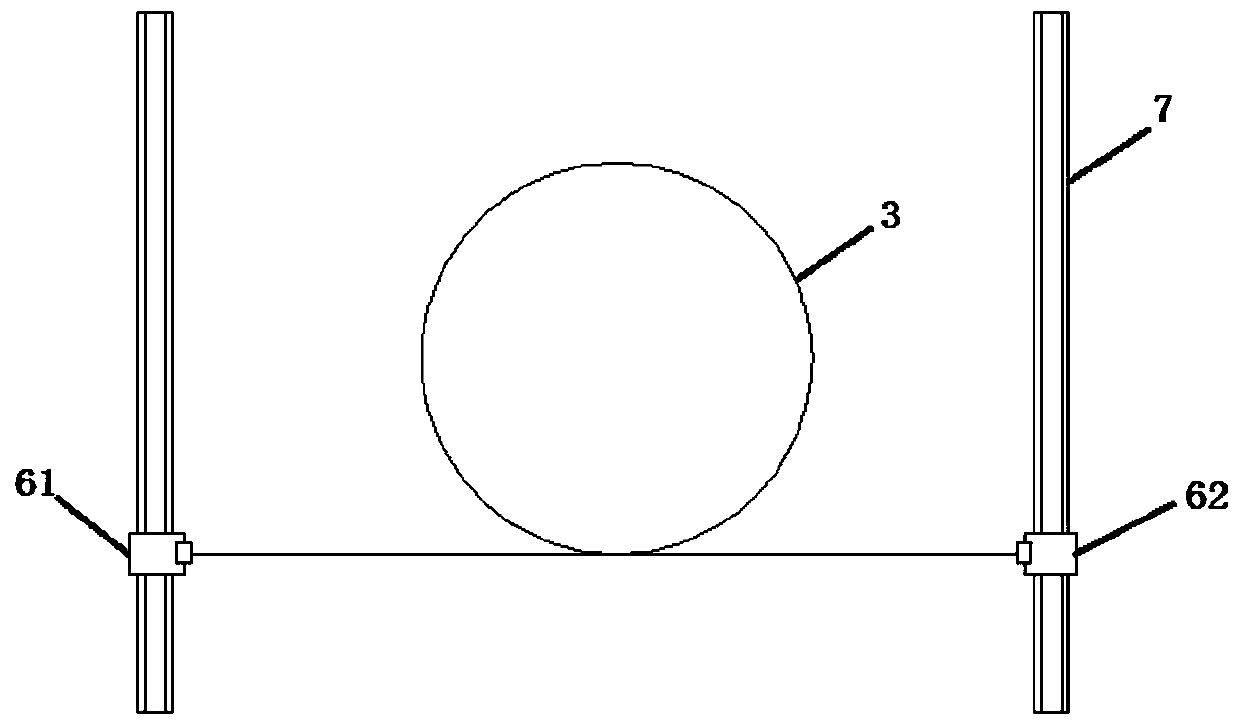

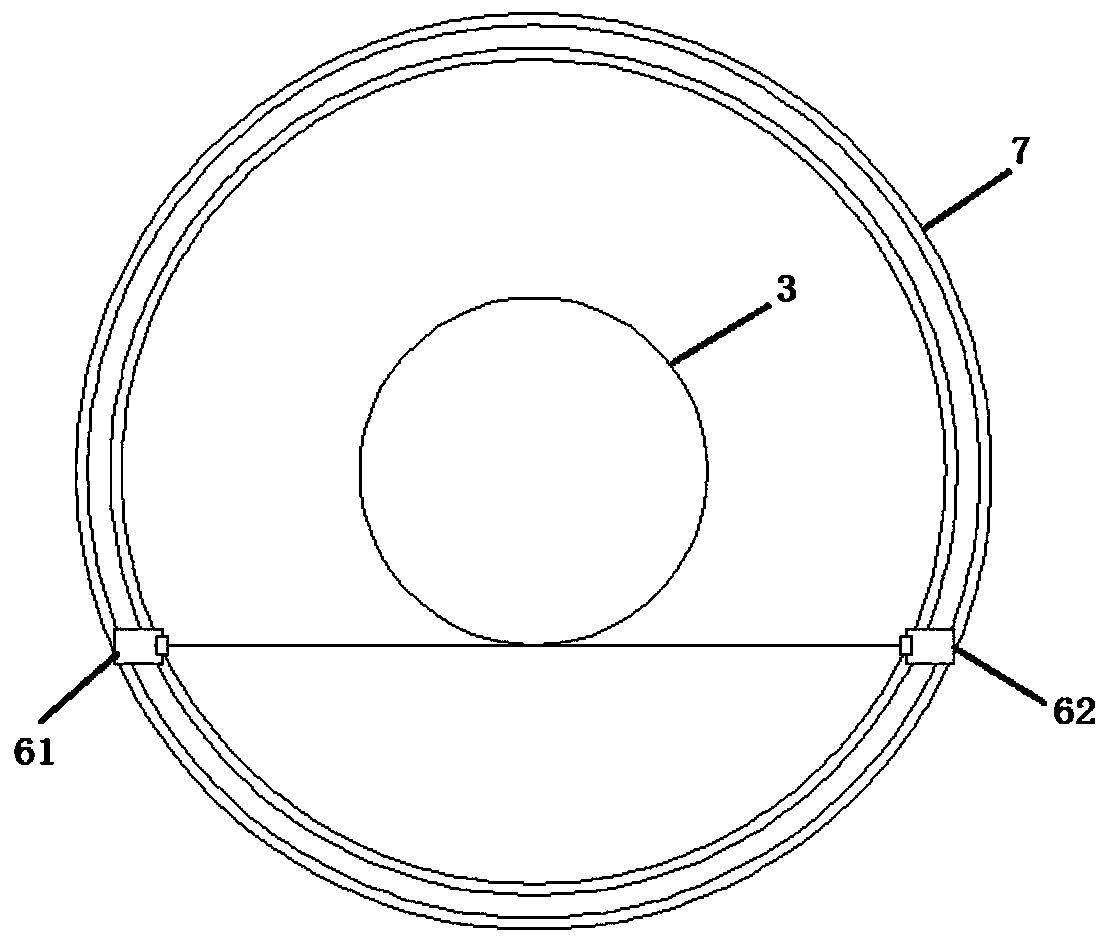

[0019] A film blowing machine with replaceable die head, such as figure 1 As shown, it includes a frame 1 and a die head 2. When the blow molding machine is working, a cylindrical film bubble 3 is suspended on the die head 2, and an inflatable tube 41 for inflating the film bubble 3 and a deflation pipe are arranged on the die head 2. The deflation pipe 42, the inflation pipe 41 and the deflation pipe 42 are respectively provided with an inflation solenoid valve 43 and a deflation solenoid valve 44, and the inflation solenoid valve 43 and the deflation solenoid valve 44 are respectively connected to two output circuits of the relay 5 Above, a laser sensor 6 is connected to the input circuit of the relay 5, the laser sensor 6 is composed of a transmitter 61 and a receiver 62, and a slide rail 7 is respectively provided on the frame 1 on both sides of the bubble 3, The slide rail 7 is equipped with a slide table 71 sliding and positioned along the slide rail, and the transmitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com