A device and method for efficiently converting methanol to light olefins

A low-carbon olefin and methanol technology, applied in the chemical industry, can solve the problems of low conversion rate, underutilized, limited C4 processing capacity, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

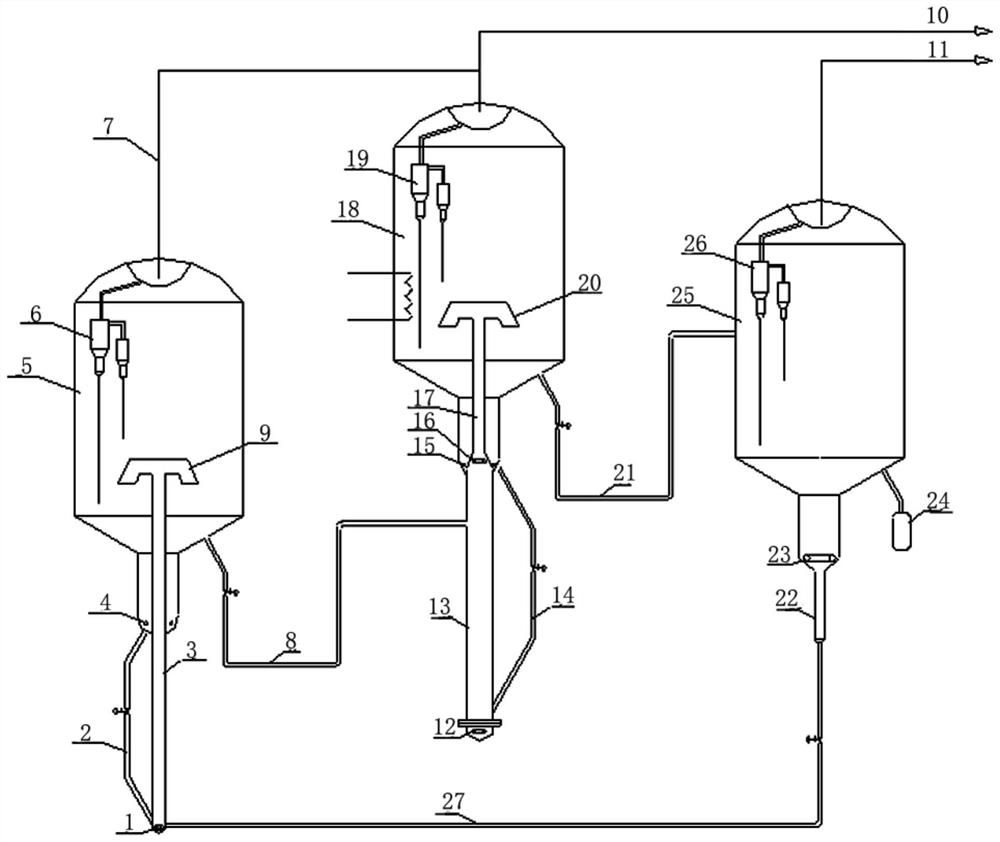

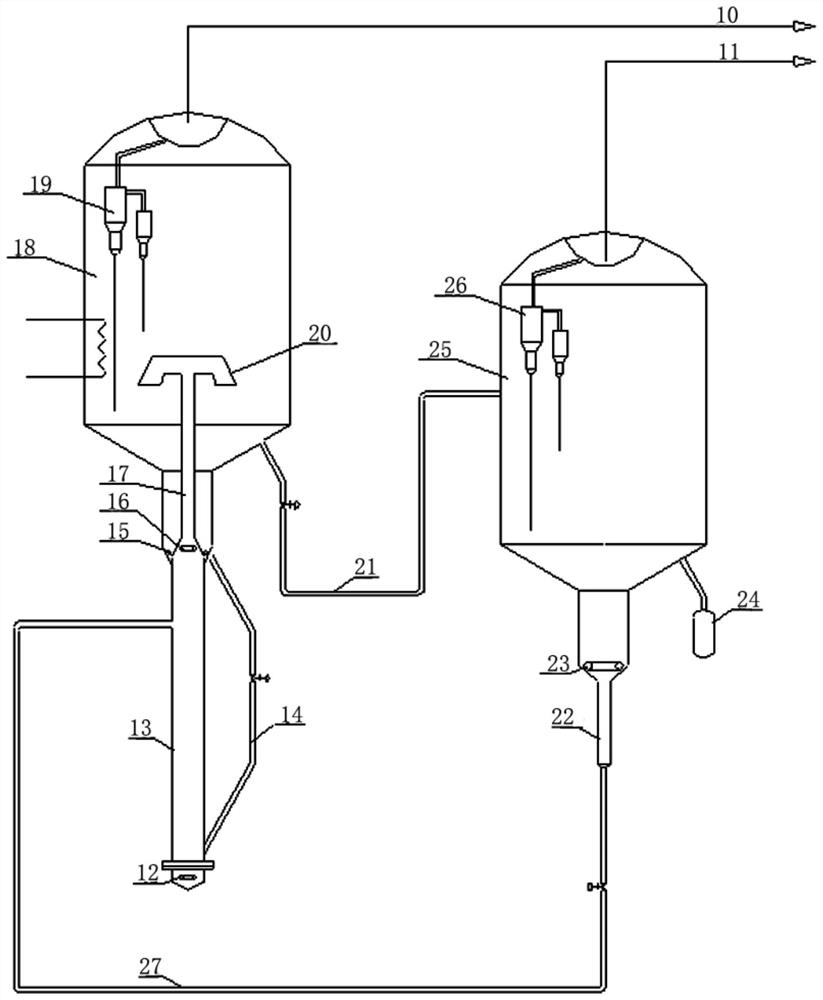

[0040] Such as figure 1 The reaction device shown, the reaction temperature of the dense phase bed reactor is 475 o C, the reaction pressure (measured by pressure gauge) is 0.25MPa, the gas linear velocity is 3m / s, and the carbon deposition amount of the catalyst is 7%; the reaction temperature of the first riser reactor is 550 o C, the reaction pressure (measured by pressure gauge) is 0.25MPa, the gas linear velocity is 5m / s, and the carbon deposition amount of the catalyst is 3%; the reaction temperature of the second riser reactor is 475 o C, the reaction pressure (measured by pressure gauge) is 0.25MPa, the gas linear velocity is 6m / s, and the carbon deposition amount of the catalyst is 8%. The feed to the first riser reactor is mixed C4 components, the olefin content is 93wt%, and does not contain methanol; the feed to the dense-phase bed reactor is methanol, and the feed amount is 5kg / h; the carbon deposition of the regenerated catalyst is 0.3wt%; The pre-coked catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com