Method for preparing monosaccharide by using raw material containing cellulose

A technology for cellulose and raw materials, applied in the field of preparing monosaccharides, can solve the problems of reducing the proportion of cellulose, reducing the yield of monosaccharides, low enzymatic hydrolysis efficiency, etc., to improve the yield, improve the sugar conversion rate, and improve the enzymatic hydrolysis efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This example illustrates the method of the present invention for the preparation of monosaccharides from cellulose-containing feedstocks.

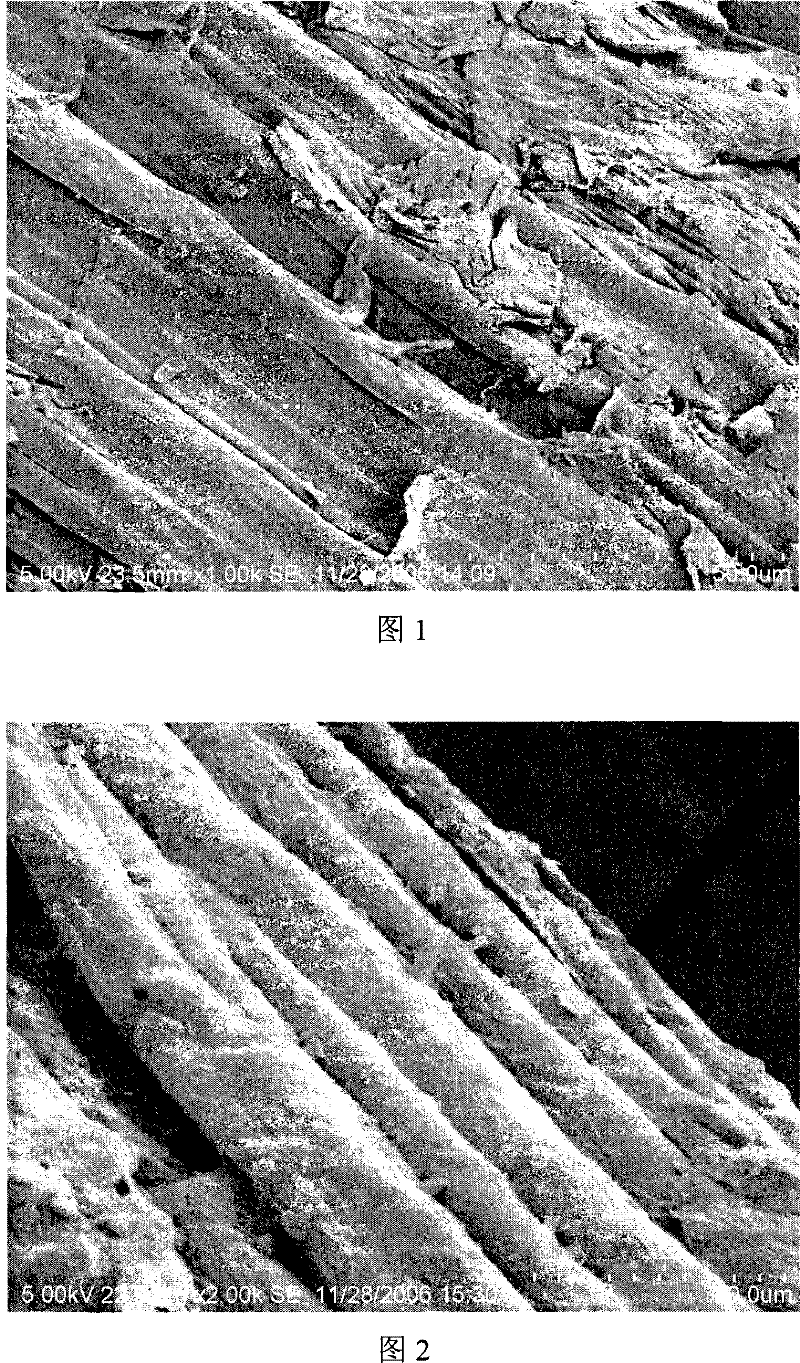

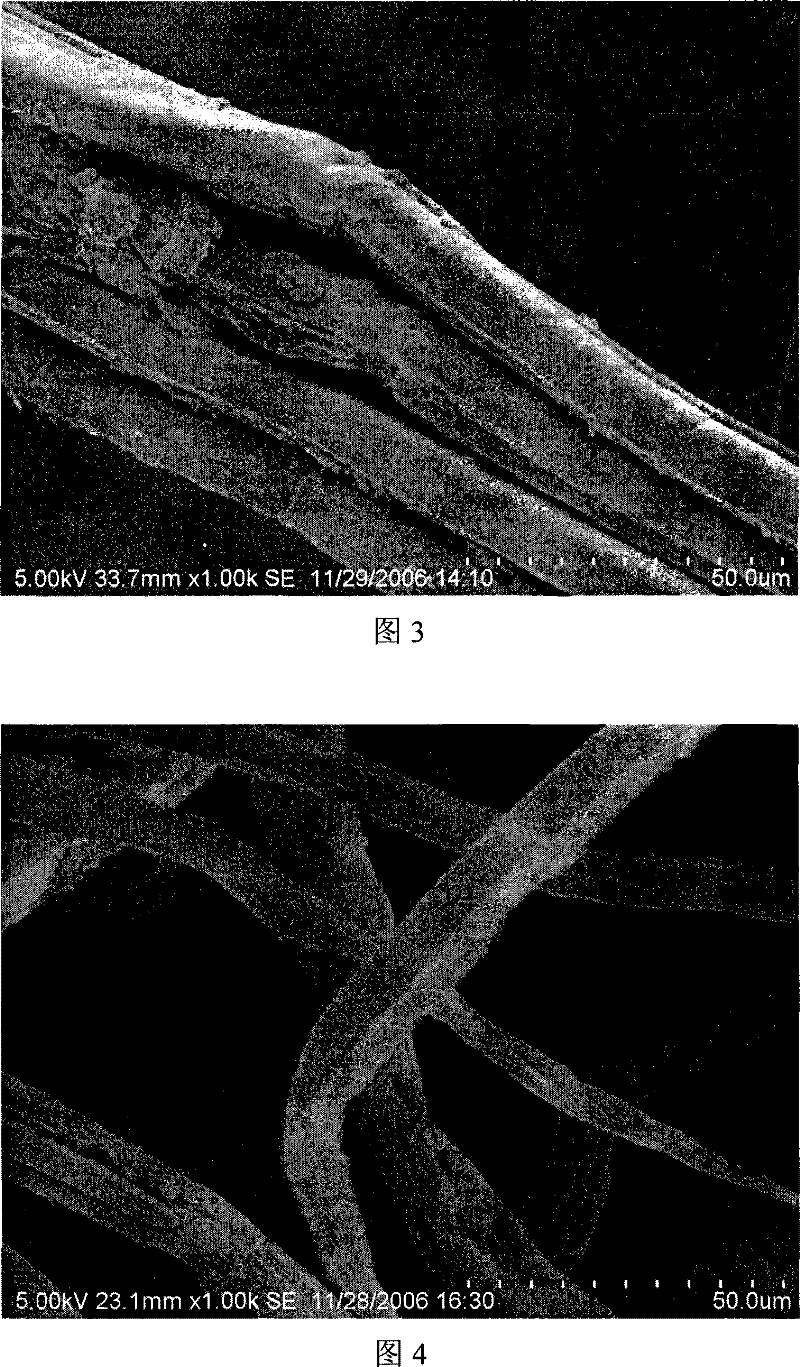

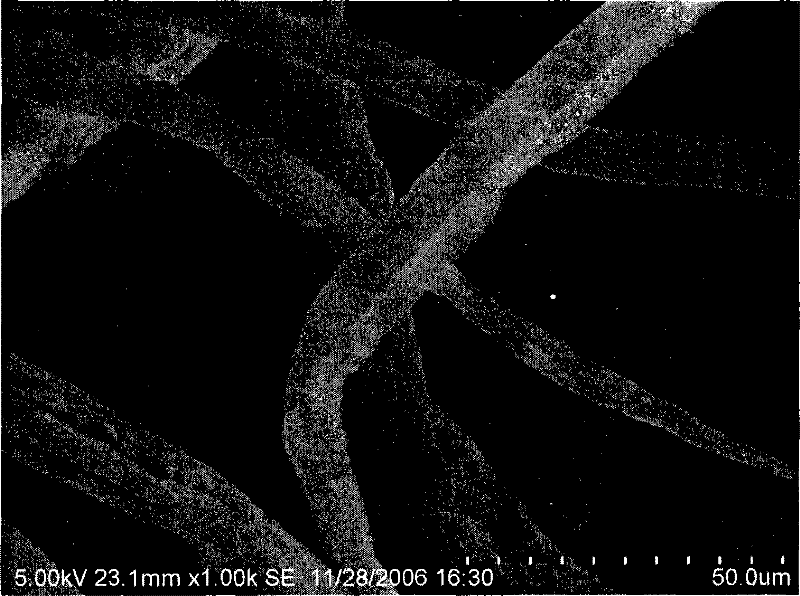

[0062] (1) Continuous steam explosion

[0063] test as figure 1 For the corn stalk raw material shown, the water content of the corn stalk measured by the above-mentioned method is 20% by weight, the raw material is cut into small sections of 1.5 cm × 0.2 cm × 0.5 cm, and the corn stalk section with a water content of 20% by weight is It is fed continuously from the feeder, and water drenched before being transported to the heat preservation pressure device, and the water drench makes the water content of the corn stalks 40% by weight. Then 2000 grams of corn stalks with a water content of 40% by weight are continuously transported to the above-mentioned heat preservation pressure device, the pressure of the heat preservation pressure device is 1.6 MPa, and the temperature is 195 ° C. Continuous transmission, the linear speed of t...

Embodiment 2

[0071] This example illustrates the method of the present invention for preparing monosaccharides from cellulose-containing feedstocks.

[0072] Monosaccharides were prepared according to the method of Example 1, except that the corn stalks with a water content of 20% by weight were water drenched to make the water content of the corn stalks 75% by weight. Then according to the conditions and methods of Example 1, 4800 grams of corn stalks with a water content of 75% by weight are continuously delivered to the heat preservation pressure device for continuous steam explosion, and the steam explosion waste is collected and washed to obtain a total of 6000 grams of solid steam explosion waste ( The water content is 80% by weight). According to the method of HPLC analysis of the steam explosion product of sulfuric acid hydrolysis described in Example 1, record 6000 grams of steam explosion product containing 520 grams of cellulose and 144.4 grams of hemicellulose.

[0073] Accord...

Embodiment 3

[0075] This example illustrates the method of the present invention for preparing monosaccharides from cellulose-containing feedstocks.

[0076] Monosaccharides were prepared according to the method of Example 1, the difference was that 1500 grams of corn stalks with a water content of 20% by weight were continuously fed from the feeder and directly transported to the heat preservation pressure device for continuous Steam explosion, the condition of steam explosion is the same as embodiment 1, obtains 2400 grams of solid steam explosion waste (water content is 50% by weight) altogether after collecting steam explosion waste and washing.

[0077] According to the method of HPLC analysis of the steam explosion product of sulfuric acid hydrolysis described in Example 1, record 2400 grams of steam explosion product containing 515.2 grams of cellulose and 142.2 grams of hemicellulose.

[0078] According to the method of Example 1, the above-mentioned steam explosion product was enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com