Method for preparing monosaccharide by using raw material containing cellulose

A cellulose and raw material technology, applied in the field of monosaccharide preparation, can solve the problems of reducing the yield of monosaccharide, reducing the proportion of cellulose, and low enzymatic hydrolysis efficiency, so as to achieve the effect of benefiting production efficiency and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This example is used to illustrate the method of the present invention for preparing monosaccharides from cellulose-containing raw materials.

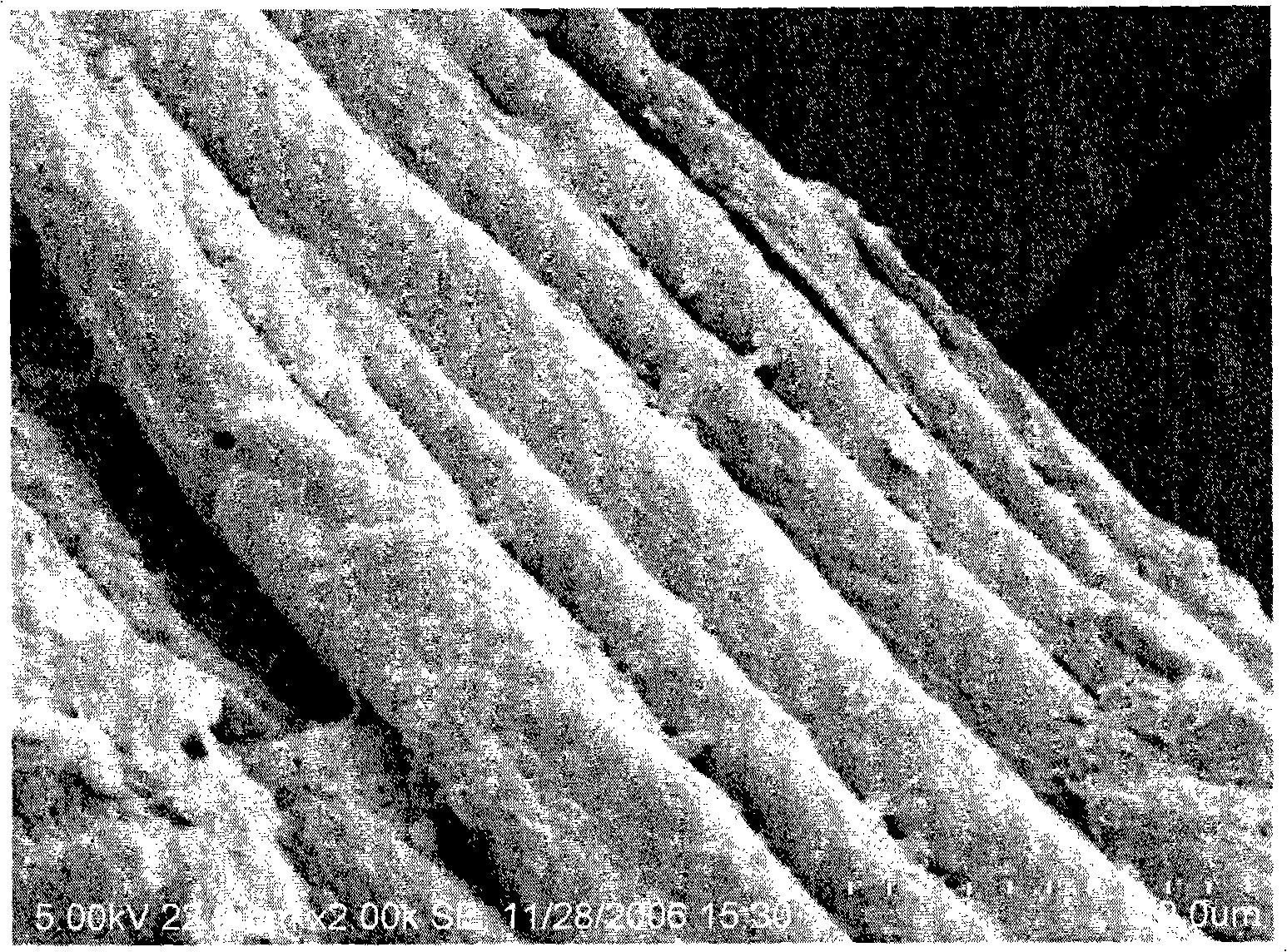

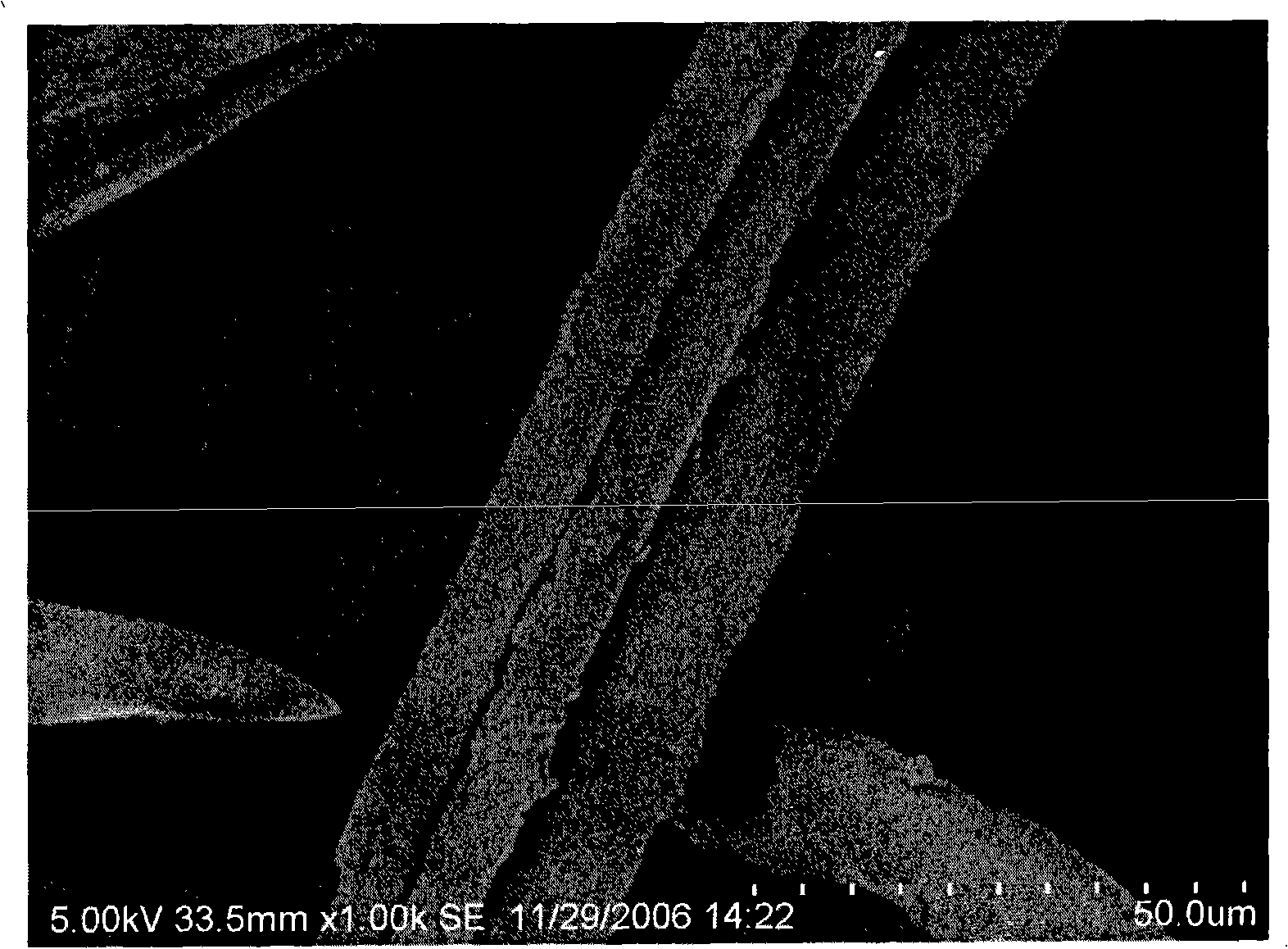

[0064] (1) Continuous steam explosion

[0065] test as figure 1 The shown corn stalk raw material, the water content of the corn stalk measured according to the above method is 20% by weight, the raw material is cut into small sections of 1.5 cm × 0.2 cm × 0.5 cm, and the water content of the corn stalk section is 20% by weight. It was continuously fed from the feeder, and was drenched with water before being transported to the heat-retaining pressure device, so that the water content of the corn stover segment was 40% by weight. Then, 2000 grams of the corn stover with a water content of 40% by weight was continuously transported to a heat preservation pressure device. The pressure of the heat preservation pressure device was 1.6 MPa and the temperature was 195°C. The corn stover was continuously maintained in the heat preserv...

Embodiment 2

[0073] This example is used to illustrate the method of the present invention for preparing monosaccharides from cellulose-containing raw materials.

[0074] The monosaccharide was prepared according to the method of Example 1, except that the corn stover with a water content of 20% by weight was continuously fed from the feeder, and was drenched with water before being transported to the heat preservation pressure device. The moisture content of the corn stover segment was 75% by weight. Then according to the conditions and methods of Example 1, 2000 grams of corn stover with a water content of 75% by weight are continuously transported to the heat-retaining pressure device for continuous steam explosion, and 3000 grams of solid steam-exploded goods are obtained after collecting the steam-exploded goods and washing with water ( The water content is 83.3% by weight).

[0075] According to the method for HPLC analysis of sulfuric acid hydrolyzed steam explosion products descri...

Embodiment 3

[0078] This example illustrates the method of the present invention for preparing monosaccharides from cellulose-containing raw materials.

[0079] The monosaccharide was prepared according to the method of Example 1, except that after 2000 grams of corn stover with a water content of 20% by weight was continuously fed from the feeder, it was directly transported to the heat preservation pressure device without water drenching for continuous continuous feeding. Steam explosion, the conditions of steam explosion are the same as in Example 1, and after collecting the steam explosion waste and washing with water, a total of 3556 grams of solid steam explosion waste (water content is 55% by weight) is obtained.

[0080] According to the method of HPLC analysis of sulfuric acid hydrolyzed steam explosion products described in Example 1, it was found that 3556 grams of steam explosion products contained 680 grams of cellulose and 193.8 grams of hemicellulose in total.

[0081] Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com