Lead-free glass powder for solar cell aluminum paste and preparation method thereof

A technology of solar cells and lead-free glass powder, applied in the field of solar conductive paste, can solve problems such as unfavorable environment and damage, and achieve the effects of large processing capacity, improved production efficiency and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

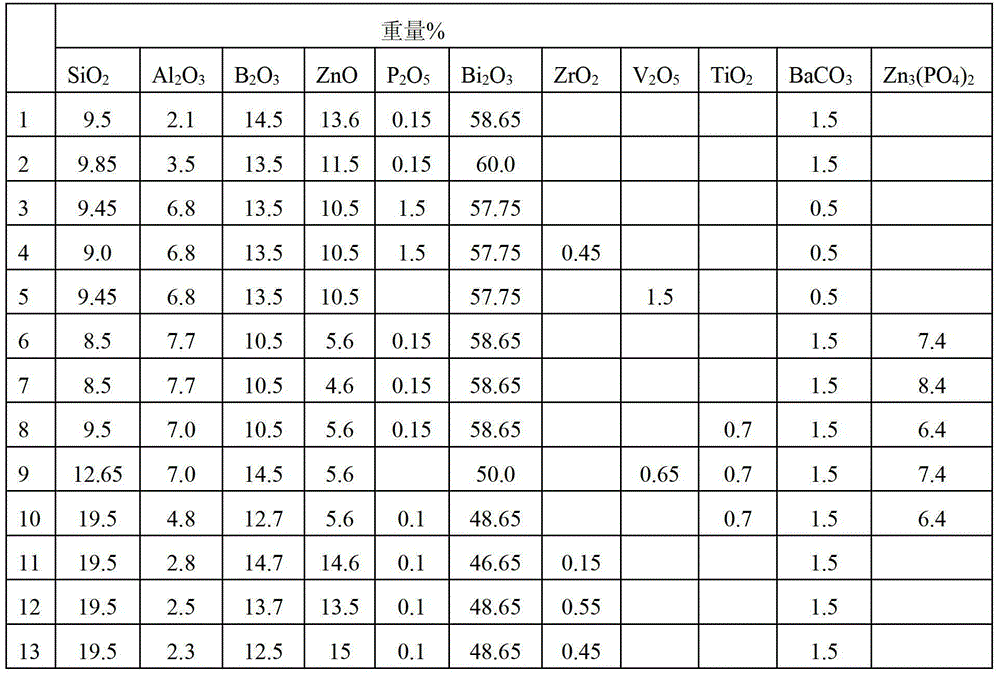

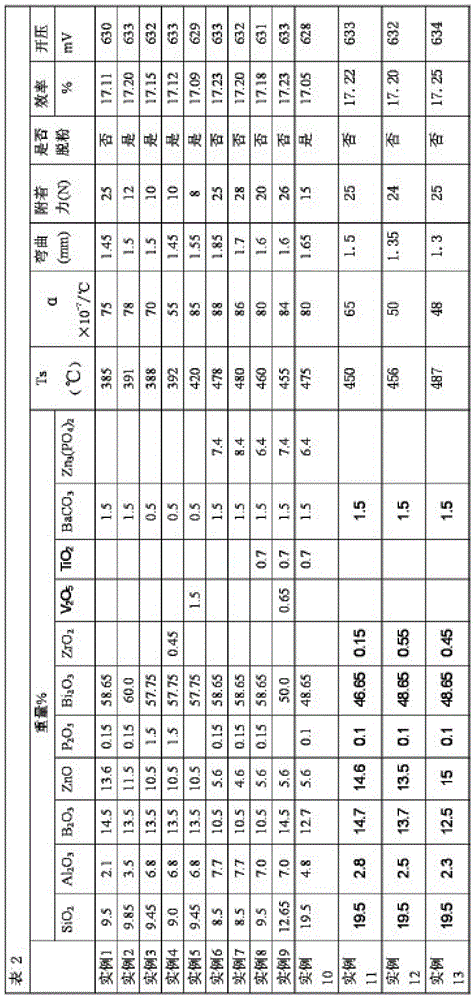

[0026] The percentage by weight of the glass frit raw material used in the present invention in the total glass composition is listed in Table 1, wherein the zinc compound and bismuth compound are also listed in the table.

[0027] Table 1

[0028]

[0029] According to the technical scheme for preparing glass powder adopted in the present invention, each component glass material is accurately weighed and mixed in a mortar according to the requirements of the formula, and the well-mixed raw materials are put into a mold and pressed into a small cylindrical shape. The height of the cylinder is 2-4cm, and the weight is 30-60g. Put the pressed block raw materials into a drying oven that can circulate and ventilate. The drying temperature is controlled at 200-350°C for 30 minutes. This process is equivalent to giving glass The material is pre-fired, and part of the water is evaporated at the same time.

[0030] In the preparation method of the present invention, in order to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com