Cooling water system and control method thereof

A cooling water system and control method technology, applied in air conditioning systems, water shower coolers, heating methods, etc., can solve problems such as increased equipment investment costs and construction costs, increased cooling water system resistance, and increased long-term energy consumption. Achieve the effect of saving project cost, easy transformation and modification, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

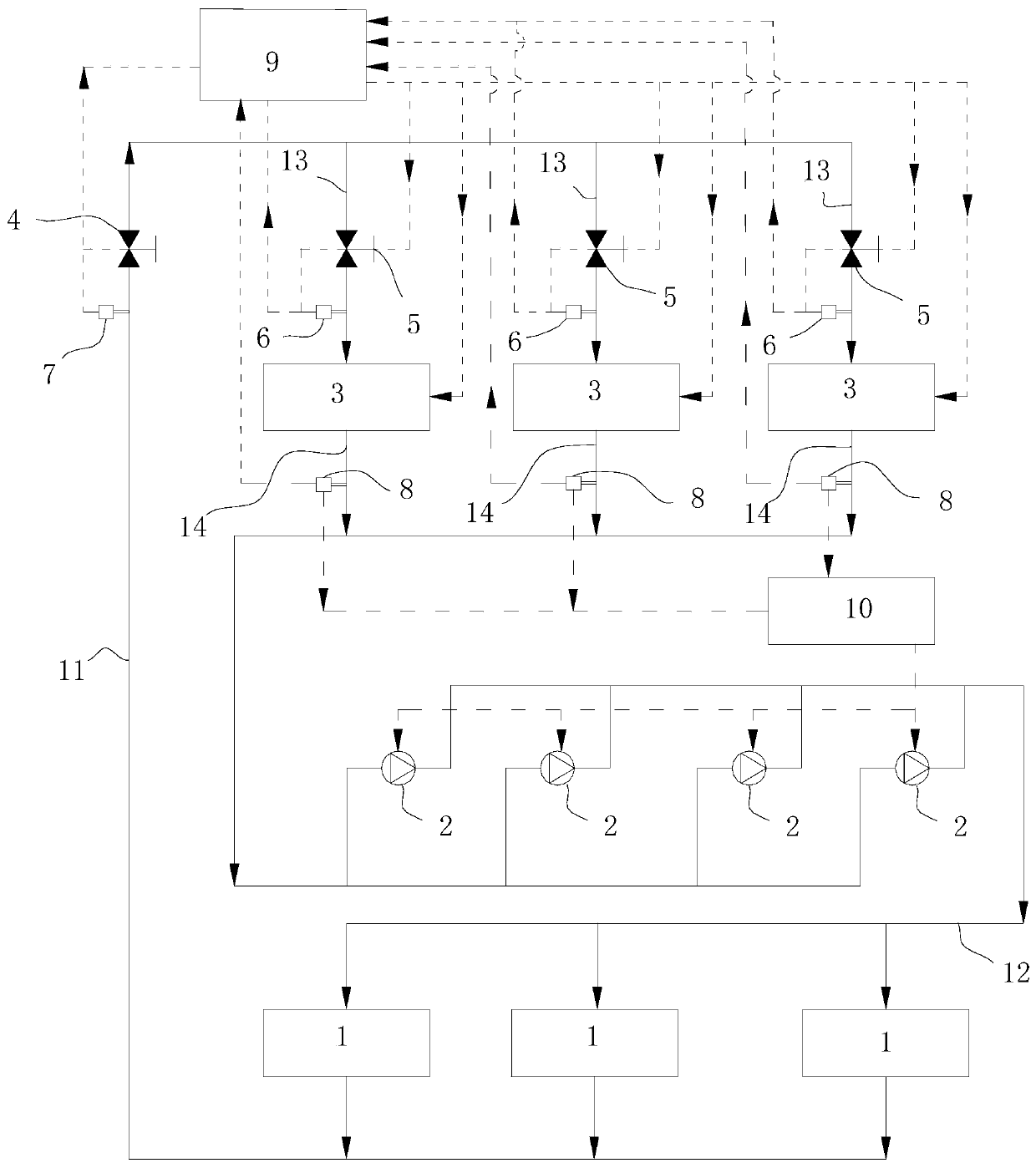

[0022] refer to figure 1 , is a cooling water system, including several refrigeration units 1, a cooling water circuit, several cooling water pumps 2 arranged in parallel on the cooling water circuit, cooling water branches arranged in parallel on the cooling water circuit, parallel arranged on the cooling water circuit Several cooling towers 3 on the water branch road are provided with fans in the cooling tower 3, wherein the cooling water circuit includes the water inlet main pipe 11 and the water return main pipe 12, and the cooling water branch road includes the water inlet branch pipe 13 and the water return branch pipe 14, and is also provided with There are a cooling system balance controller 9 and a cooling water pump frequency conversion controller 10, a main pipe flow balance valve 4 for controlling the total amount of water inflow is provided on the water inlet main pipe 11, and a main pipe flow balance valve 4 for controlling the total amount of water inlet is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com