Divergence angle adjustable beam expander

A technology of beam expander and divergence angle, applied in the direction of optical components, optics, instruments, etc., can solve the problems of small adjustment range, low positioning accuracy, and poor adjustment accuracy, and achieve high safety and reliability, simple installation and debugging, and adjustment accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

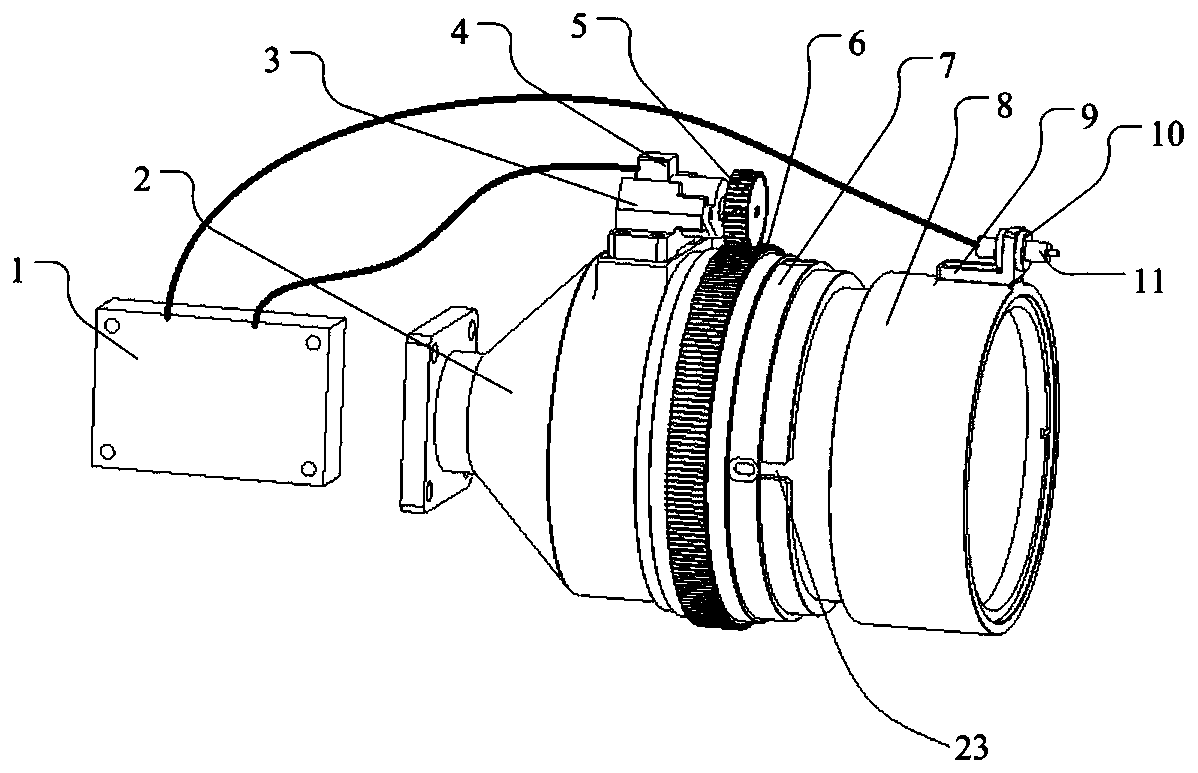

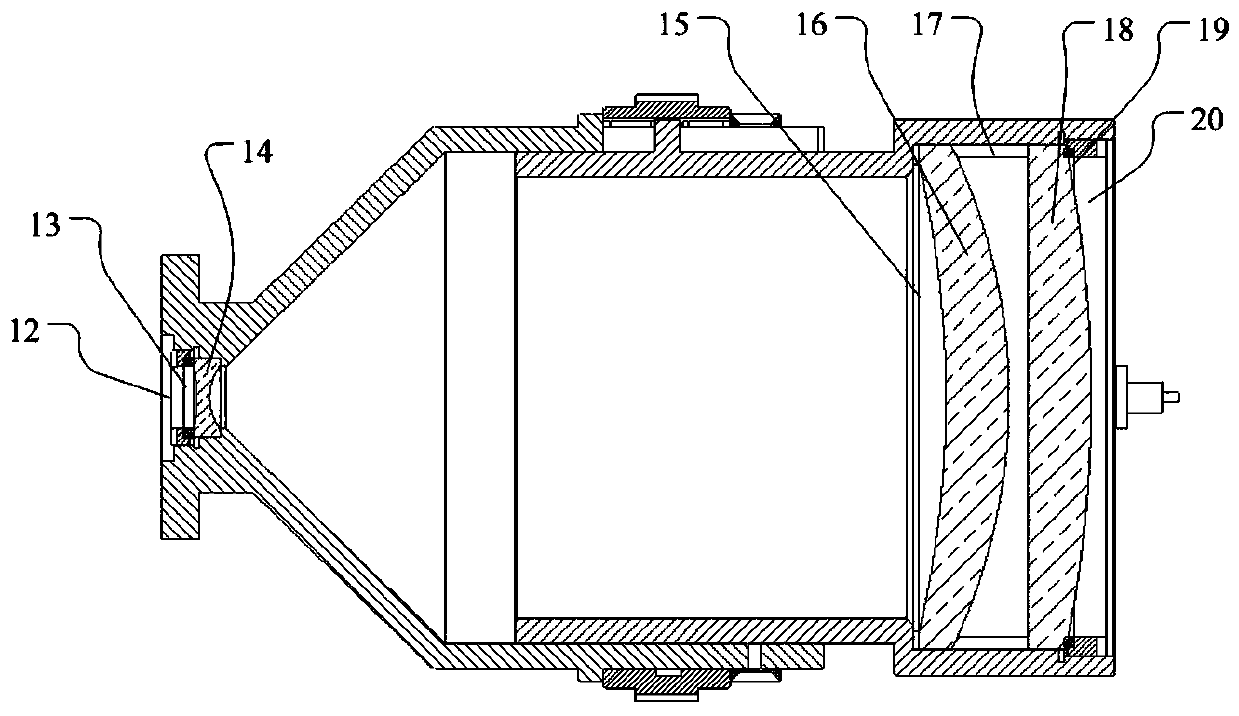

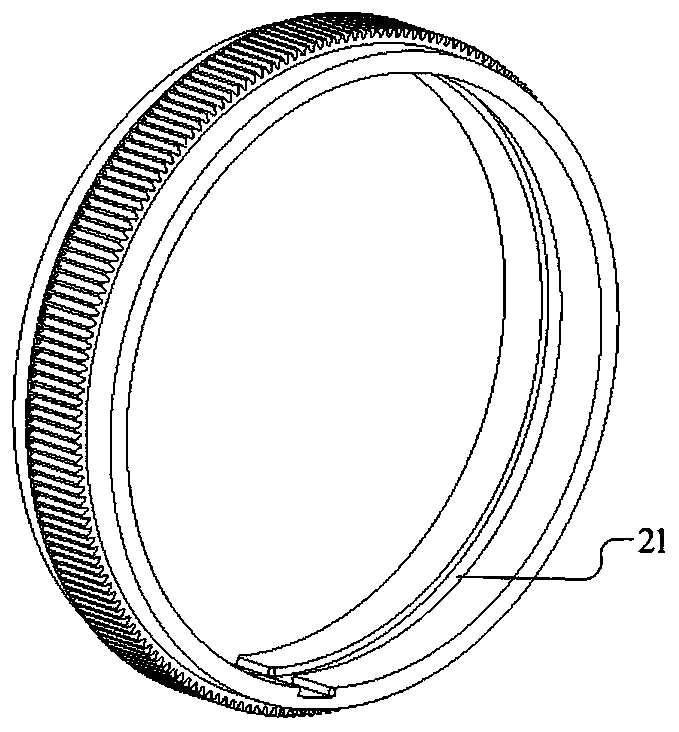

[0026] see Figure 1 to Figure 4 , a beam expander with adjustable divergence angle, including a drive control circuit 1, a first beam expander barrel 2, a second beam expander barrel 8, a stepping motor 4, a limit sensor 11, the first beam expander The head of the lens barrel is sleeved on the afterbody of the second beam expander lens barrel, the driving gear 5 is installed on the output shaft of the stepping motor, and the driven gear 6 and the gear limiter are sleeved on the first beam expander lens barrel. Position lock ring 7, the gear limit lock ring is fixed on the first beam expander lens barrel, the driving gear meshes with the driven gear, and the inner side of the driven gear is provided with annular guides with different pitches Slot 21, the tail of the second beam expander barrel is provided with a plurality of guide columns 22, the head of the first beam expander lens barrel is provided with a plurality of open grooves 23, and the plurality of guide columns pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com