Modularized/standardized production method of spatial optical system

A technology of space optics and production methods, applied in the field of optics, can solve the problems of inability to divide labor and module production, require high professional level of operators, and high technical operation requirements, achieve convenient division of labor and modular production, ensure consistency of installation positions, Neat and compact overall shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

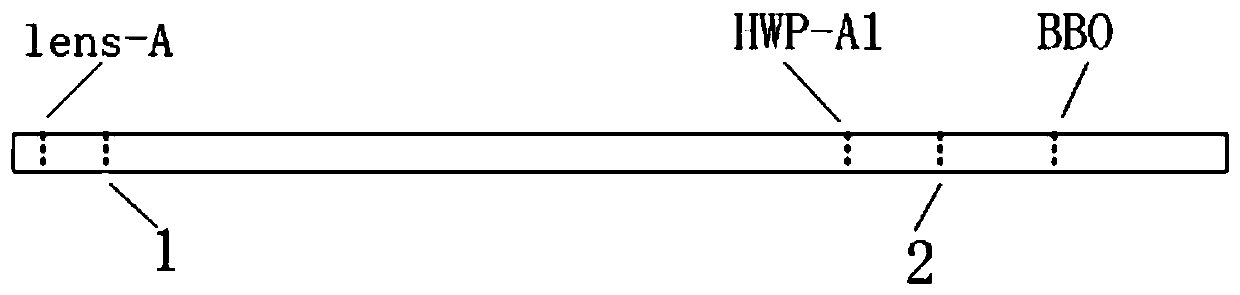

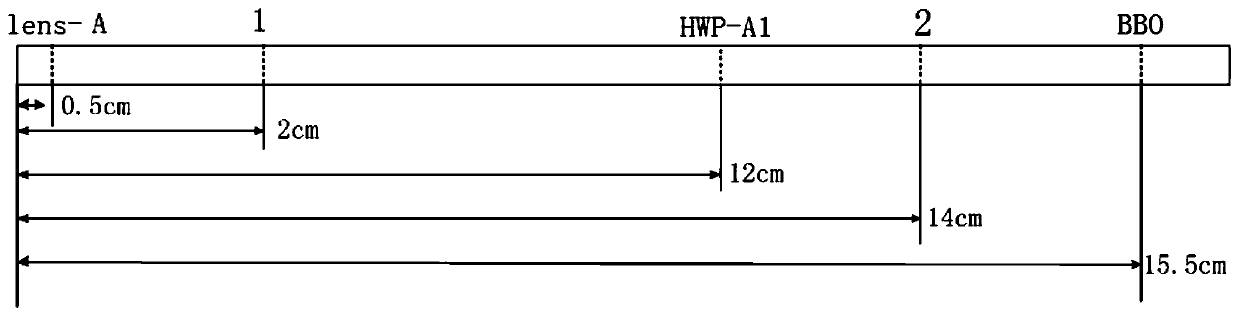

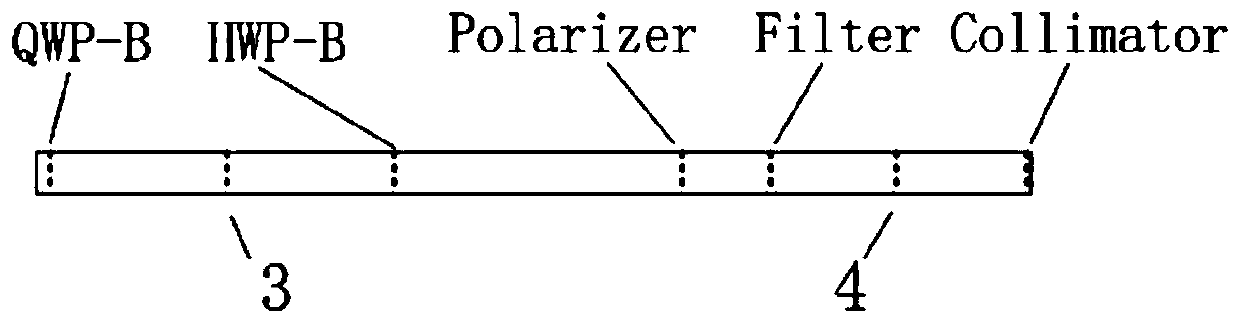

[0042] The following is based on Figure 1 to Figure 7 The specific embodiment of the present invention is further described:

[0043] A modularized / standardized production method for a space optical system, characterized in that it comprises:

[0044]Step 1: Divide all optical elements in the space optical system into modules, so as to divide them into multiple structural modules;

[0045] Specifically: according to the direction of the optical path in the space optical system, the optical elements with the same optical path are divided into one category, so as to be divided into multiple types of structural modules; or according to the different functions formed by multiple optical elements in the space optical system, the Space optics systems are divided into several types of structural modules.

[0046] Step 2: Select suitable cage system accessories for each structural module according to the number of optical elements and optical characteristics in the structural modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com