Sweeping car for ion scraps and oil stains

A technology for cleaning vehicles and iron filings, which is applied in the direction of cleaning carpets, floors, and cleaning equipment. It can solve the problems of high labor intensity, personnel punctures, and punctures, and achieve the effect of increasing the difficulty of cleaning and facilitating cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

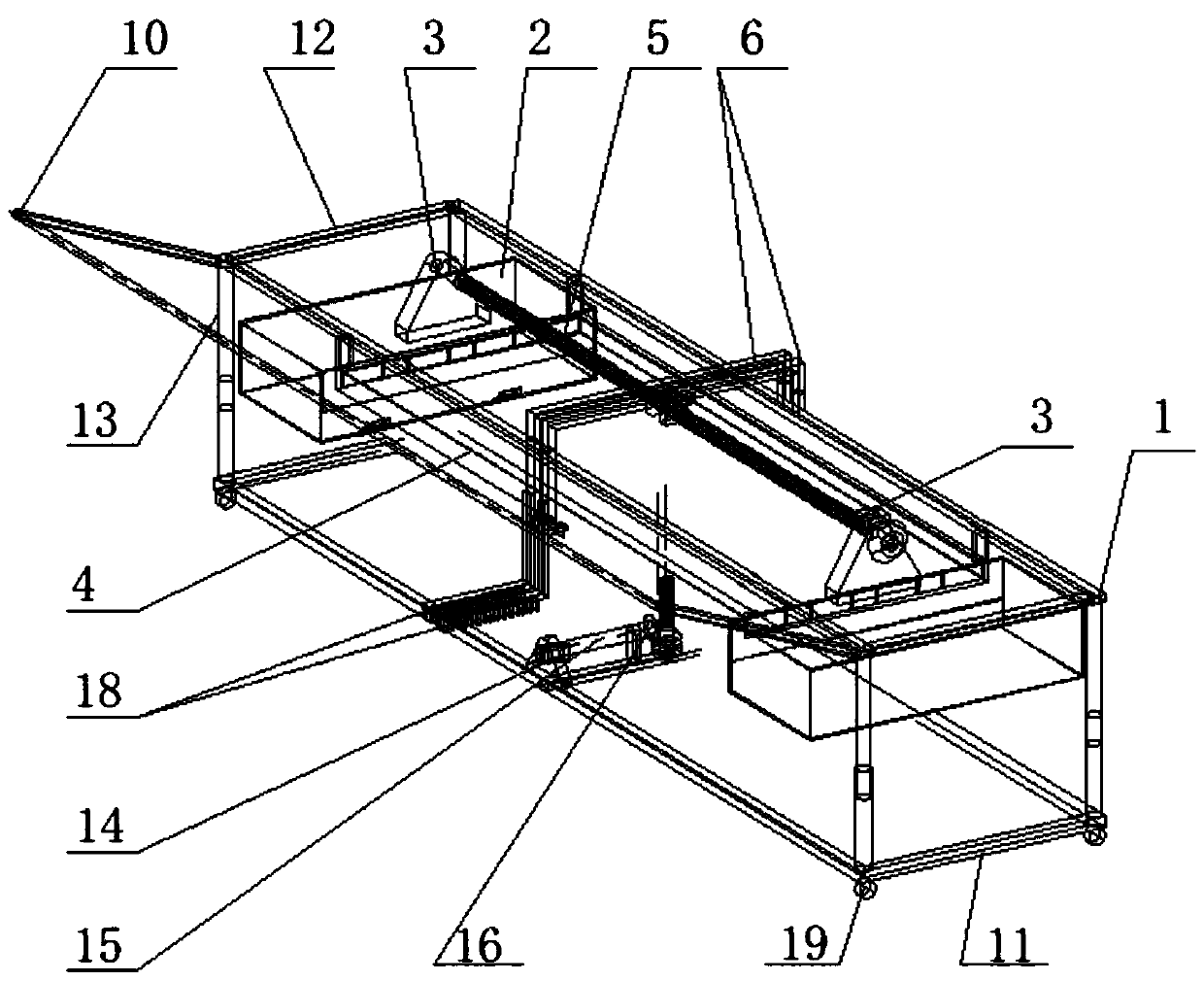

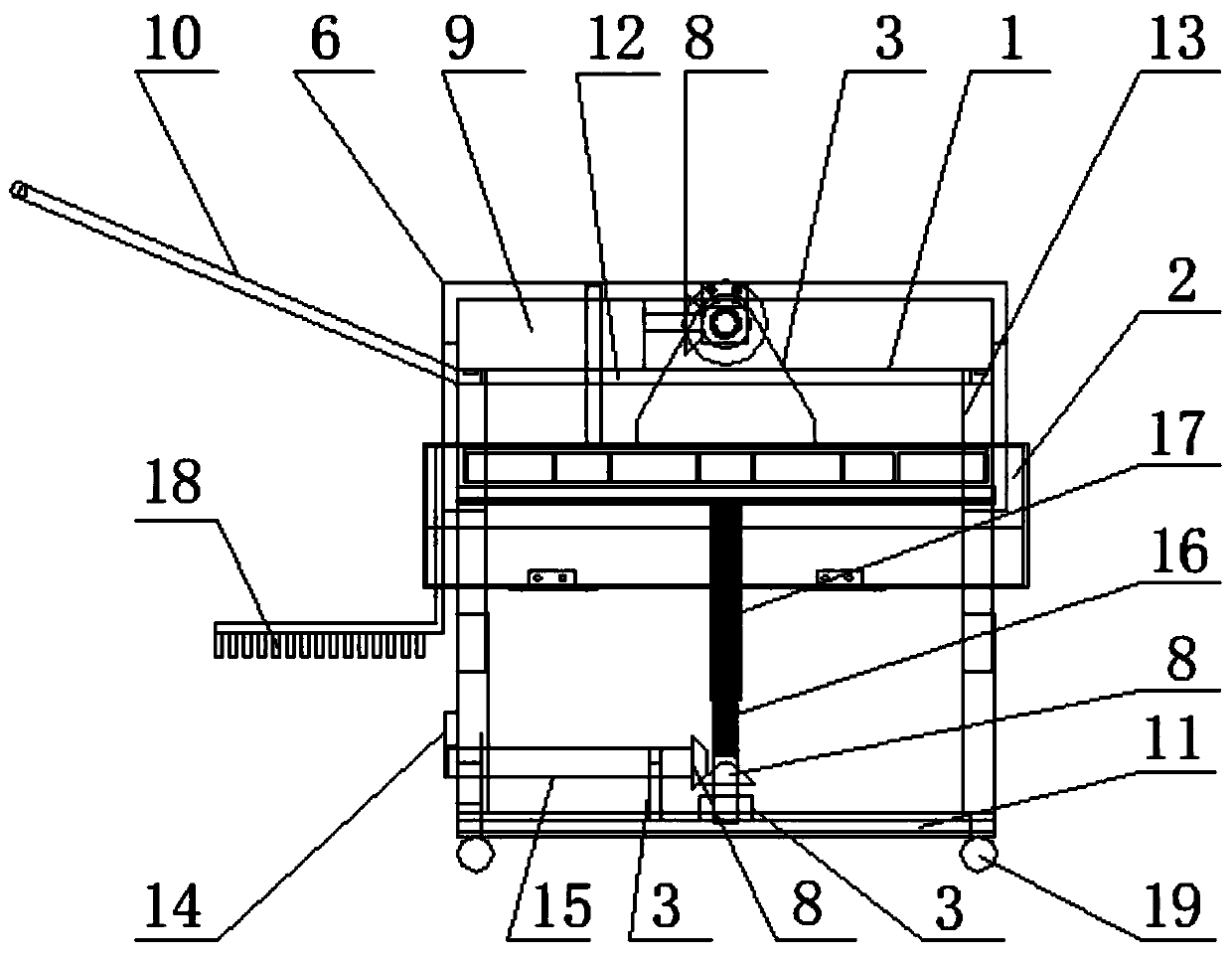

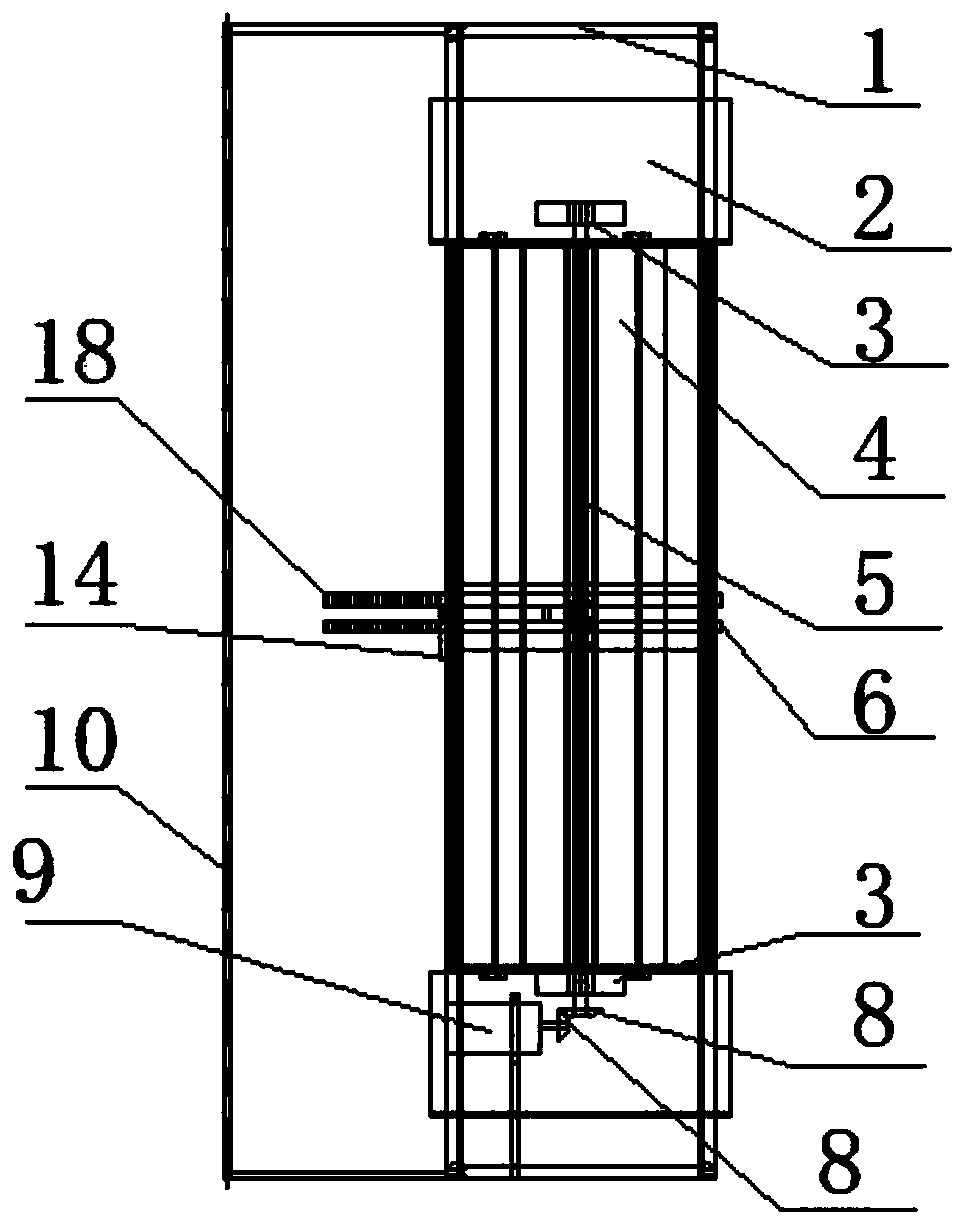

[0025] see Figure 1 to Figure 5 , an iron filings oil stain cleaning vehicle, comprising a lifting support frame 1, an iron filings collection box 2, a ferromagnetic plate 4, a lifting mechanism, an iron filings separation mechanism, an oil brush 18 and a universal wheel 19; the lifting support frame 1 includes the first A support frame 11, the second support frame 12 and the elevating rod 13, the elevating rod 13 is used for the supporting connection of the first supporting frame 11 and the second supporting frame 12, and one end of the elevating rod is connected with the first supporting frame, and the other end of the elevating rod One end is connected with the second support frame; in the present embodiment, the quantity of elevating rods is four piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com