Strip-shaped workpiece automatic inspection device

An automatic detection device and detection device technology, applied in sorting and other directions, can solve problems such as low efficiency, manufacturing errors of inspection tools and measuring tools, and different measurement methods from person to person, so as to achieve the effect of ensuring continuity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

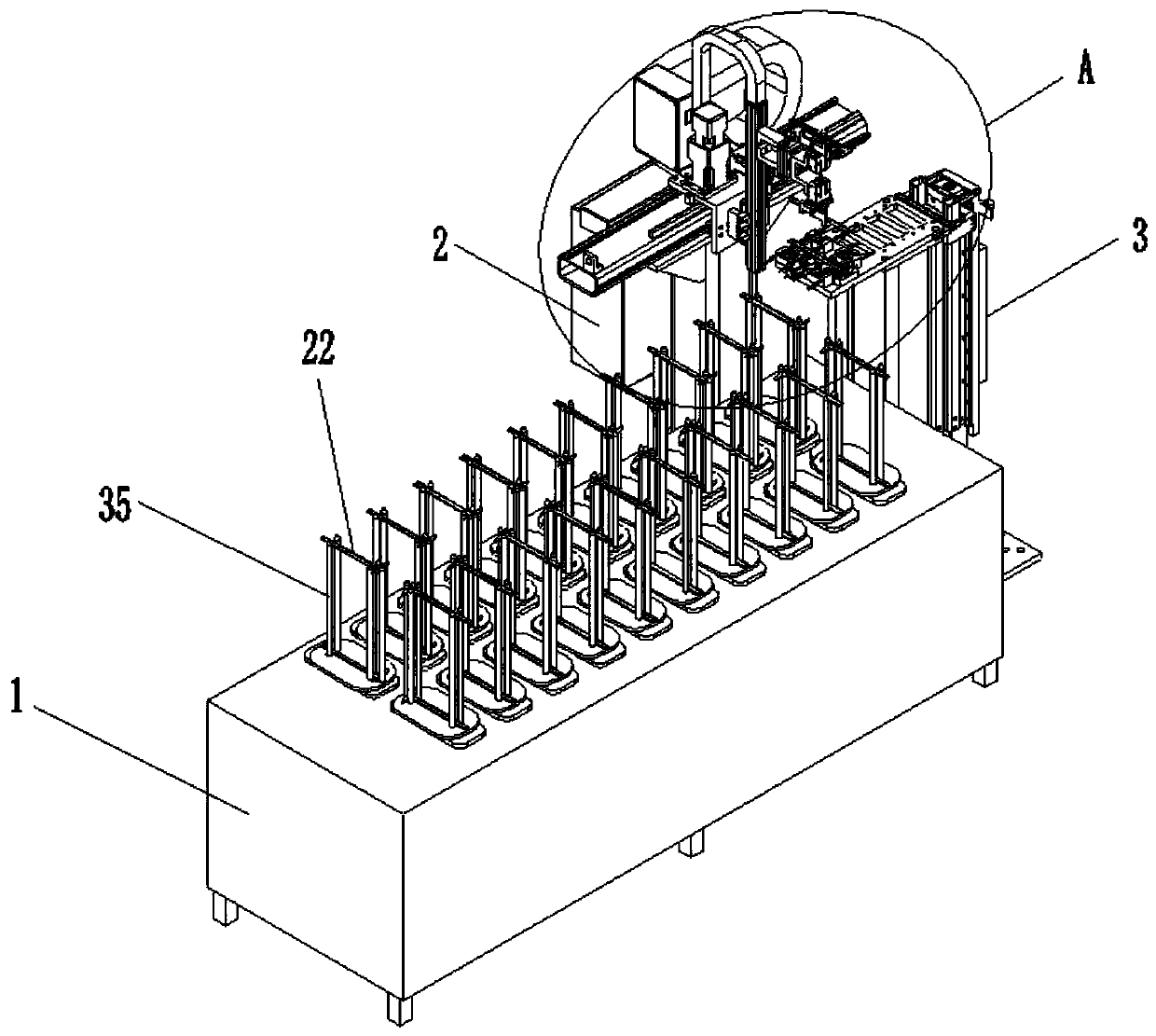

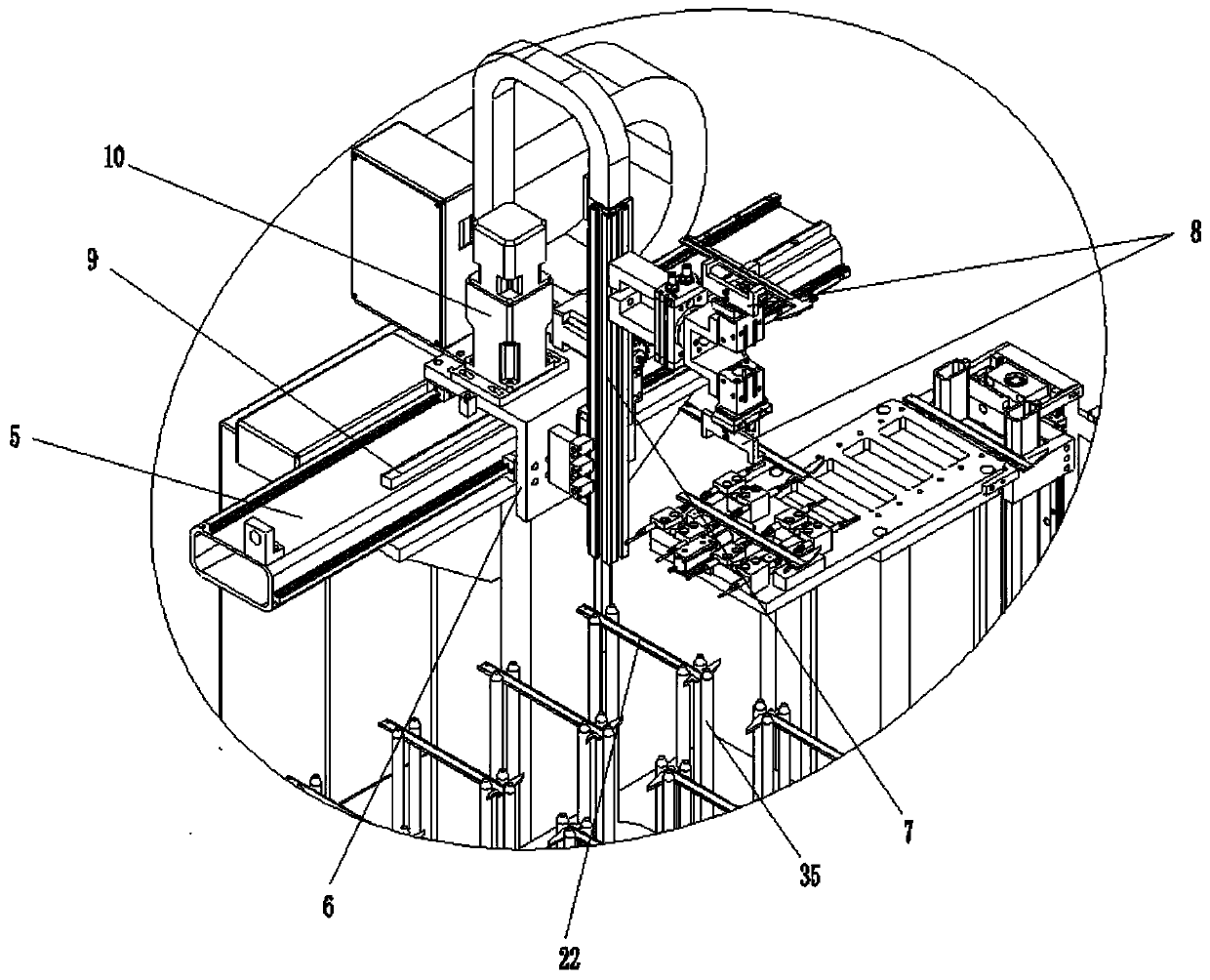

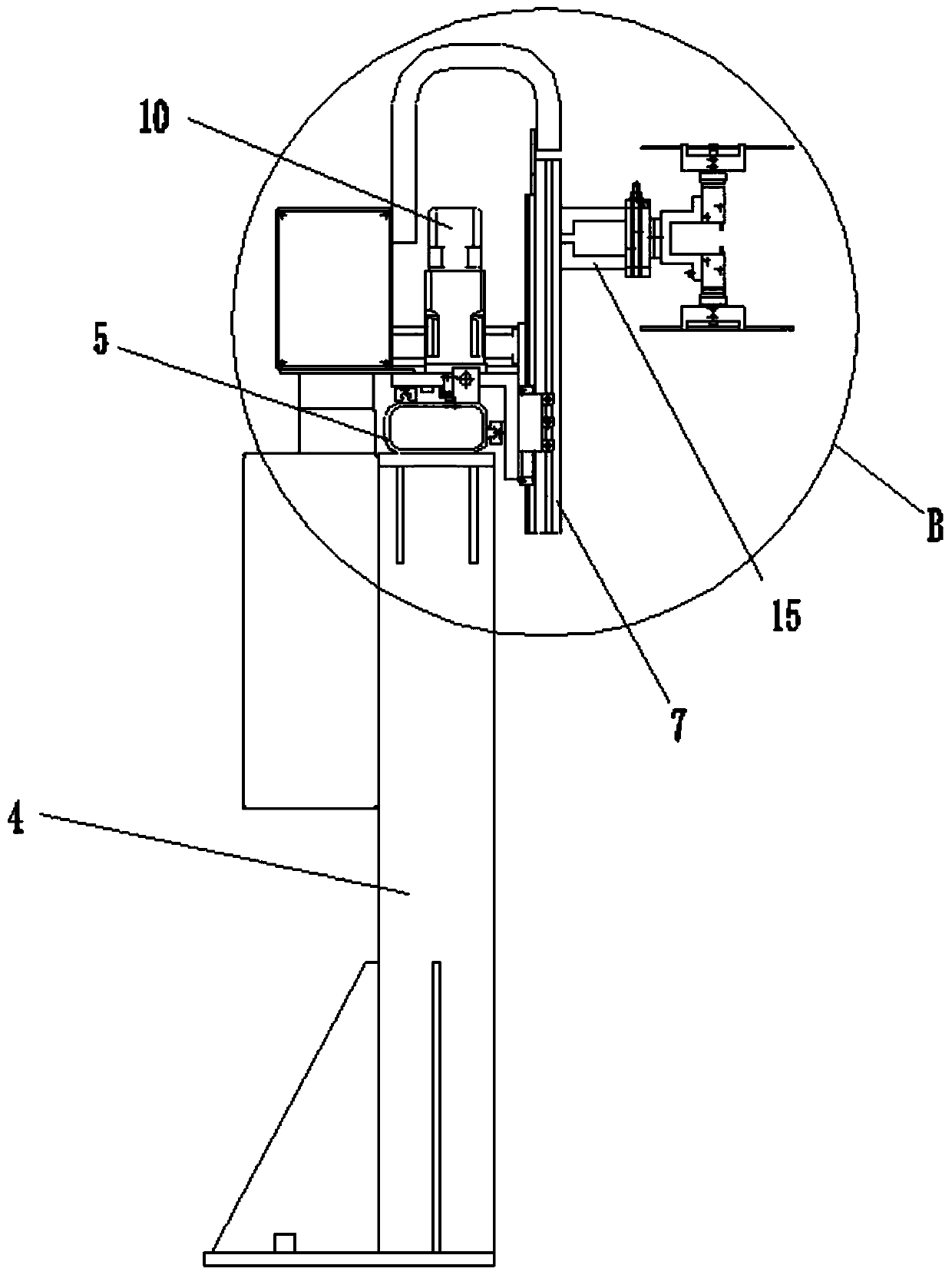

[0039] Such as figure 1As shown, an automatic detection device for elongated workpieces includes a multi-station silo 1 , a grabbing device 2 and a detection device 3 . Such as Figure 12 As shown, the multi-station silo 1 includes a machine platform 34 and a plurality of support rods 35, the machine platform 34 is provided with a plurality of loading stations, each of the loading stations is provided with a The support bar 35 that lifts up the strip-shaped workpiece 22 to be detected. The detection device 3 is located at the front of the multi-station silo 1 and is provided with a detection station for detecting the external dimensions of the elongated workpiece 22 and a storage station for placing unqualified el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com