Glass linear edge grinding machine for tempered glass production

A technology of tempered glass and edging machine, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problems of low grinding efficiency and insufficient protection of glass grinding equipment, and can provide The effect of protection, improved stability, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

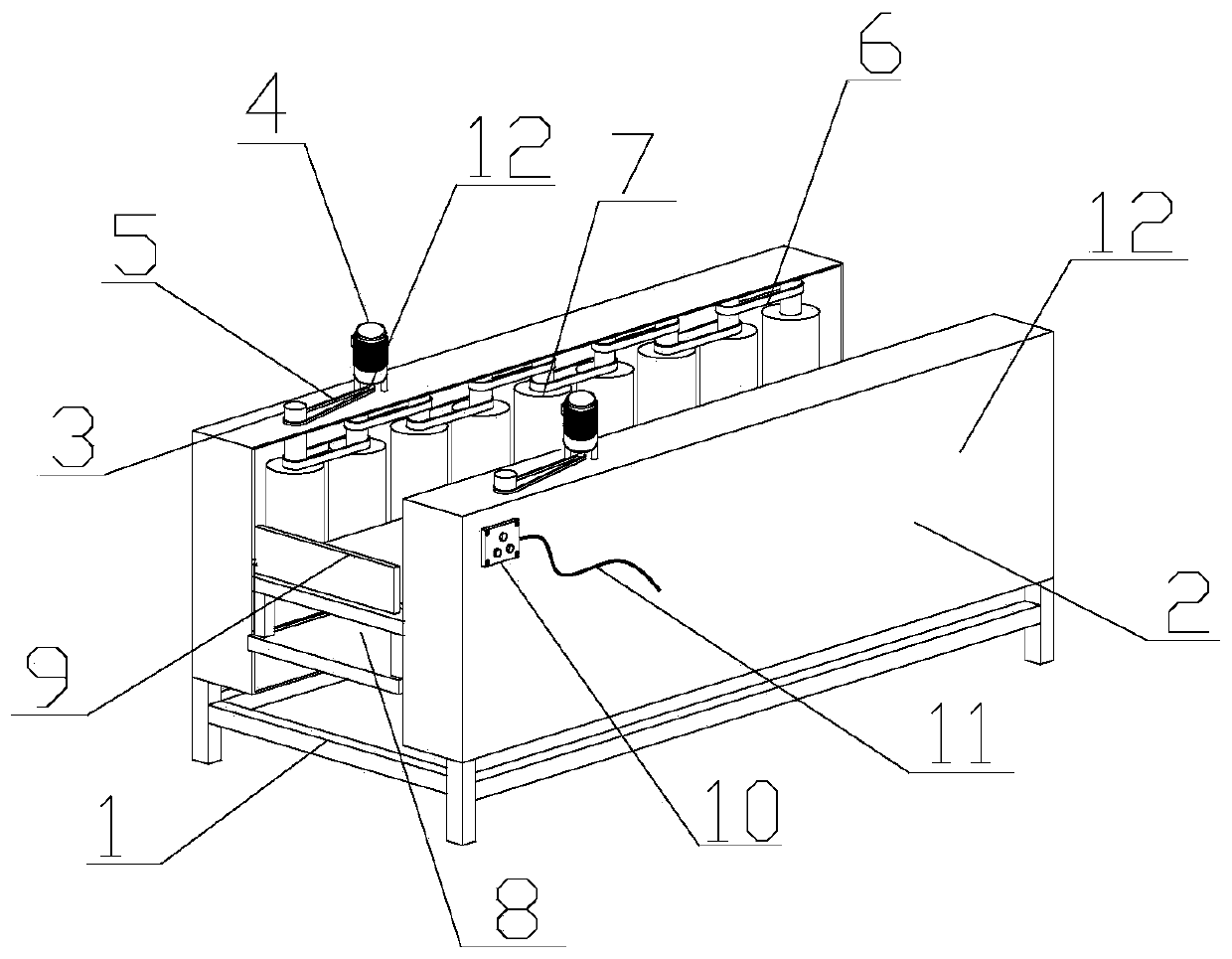

[0032] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a glass linear edging machine for tempered glass production: comprising,

[0033] bracket 1;

[0034] The left and right parts of the top of the bracket 1 are welded with a grinding device 13;

[0035] A reciprocating device 8 is provided at the middle and lower part between the grinding devices 13, and a fixing device 9 is provided at the top of the reciprocating device 8;

[0036] A switch 10 is connected to the outer side of the polishing device 13 by bolts, and a power cord 11 is provided at the rear end of the switch 10 .

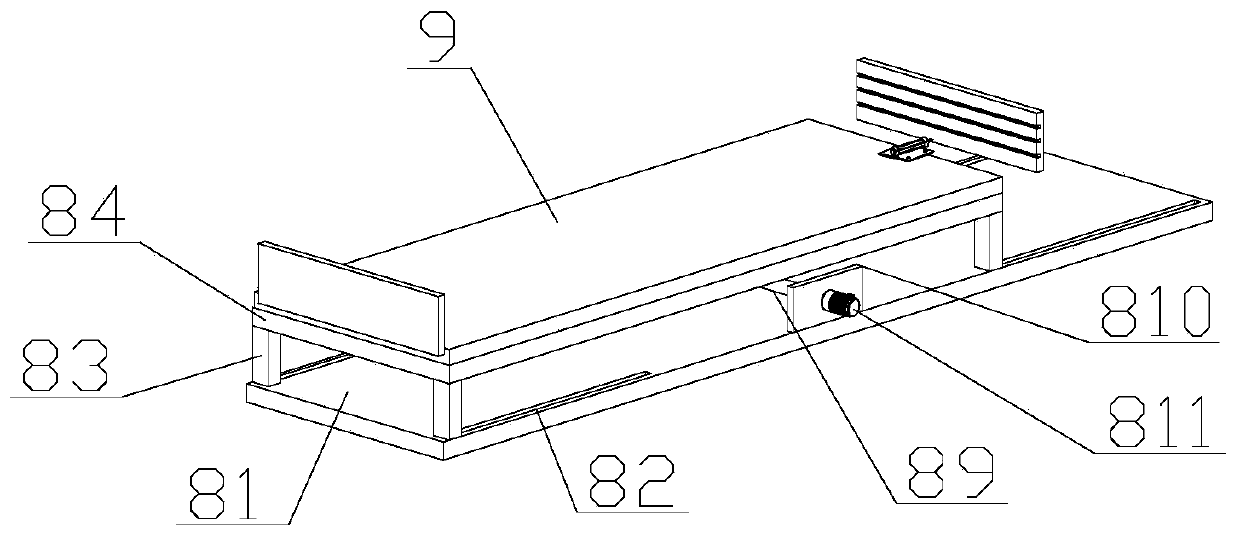

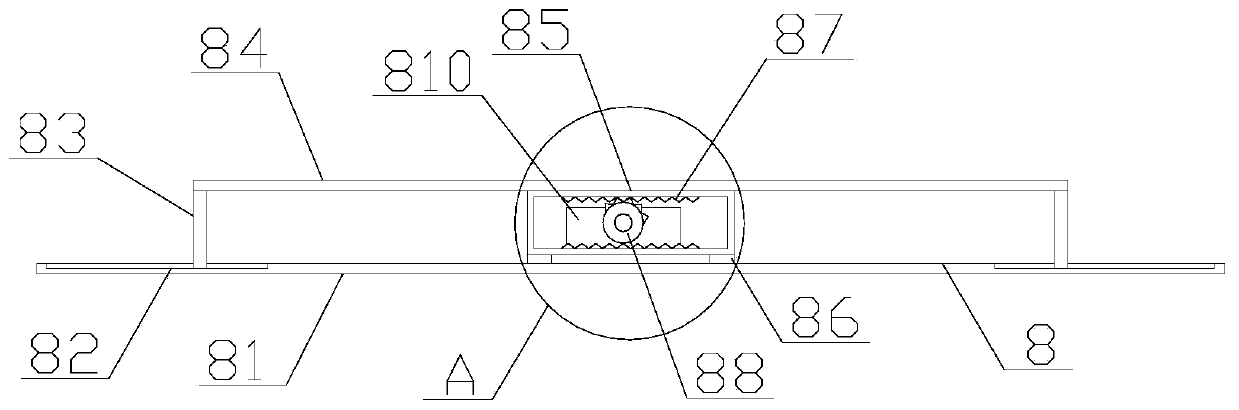

[0037] Wherein, the reciprocating device 8 includes a bottom plate 81, a chute 82, a slide bar 83, a mounting plate 84, a return frame 85, a locking block 86, gear teeth 87, a rotating wheel 88, a rotating shaft 89, a support plate 810 and a second Two driving motors 811, the four corners of the top of the bottom plate 81 are all provided with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com