Workpiece polishing robot

A technology for robots and workpieces, applied in the field of robots, can solve the problems of continuous movement of workers and uneven grinding, and achieve the effect of saving manpower, uniform grinding and easy grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

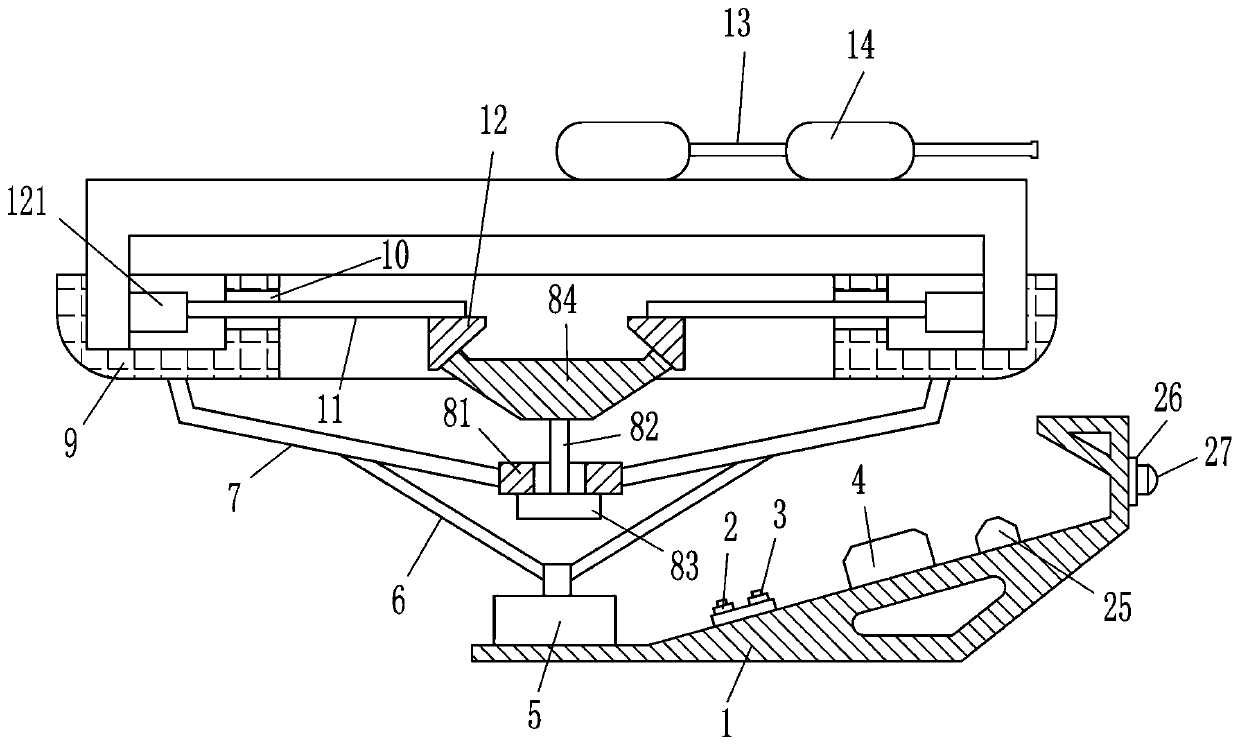

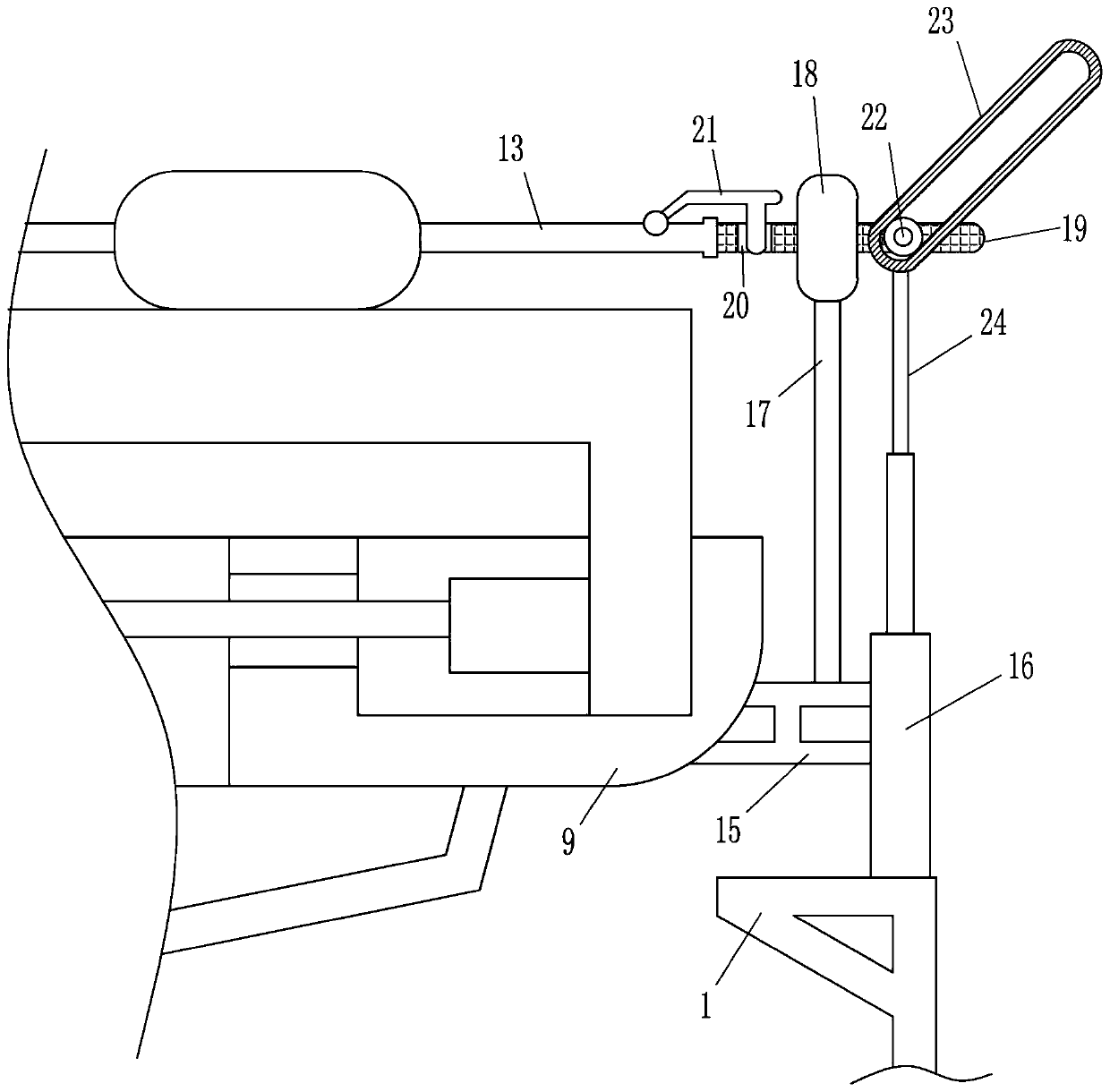

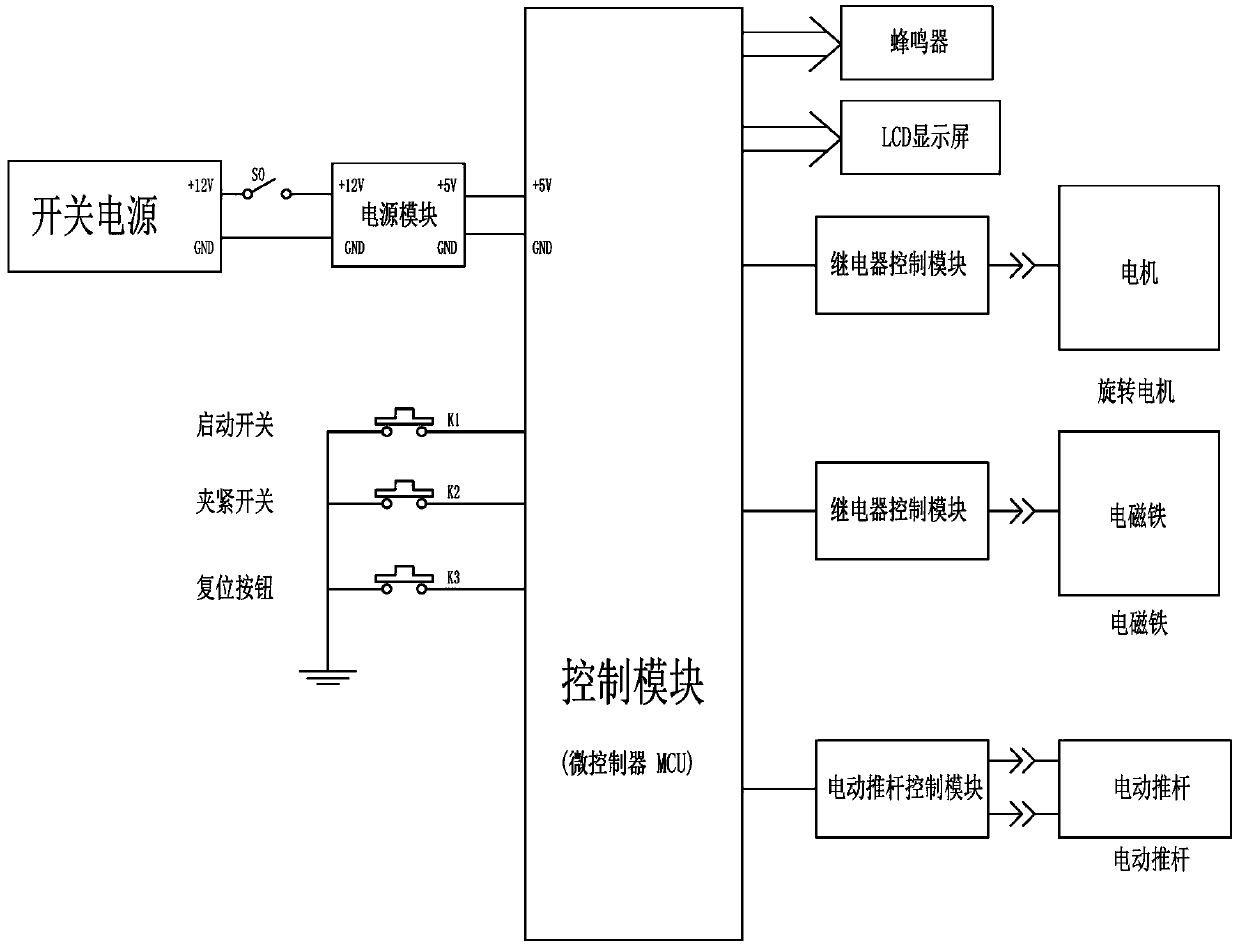

[0019] A workpiece grinding and polishing robot, such as Figure 1-3 As shown, it includes a fixed frame 1, a start switch 2, a clamp switch 3, a control box 4, a rotating motor 5, a connecting rod 6, a support rod 7, a clamping device 8, a ring frame 9, a moving rod 11, and a triangular block 12 , clamping block 121, grinding rod 13 and grinding block 14, start switch 2 and clamping switch 3 are installed on the left side of the inner bottom wall of the fixed frame 1, the starting switch 2 is located on the left side of the clamping switch 3, the inner bottom of the fixed frame 1 A control box 4 is installed in the middle of the wall, and the control box 4 includes a switching power supply, a power module and a control module. A rotating motor 5 is installed on the left side of the inner bottom wall of the fixed frame 1. The rotating motor 5 is located on the left side of the start switch 2. The rotating motor 5 The left and right sides of the output shaft of the output shaft...

Embodiment 2

[0021] A workpiece grinding and polishing robot, such as Figure 1-3 As shown, it includes a fixed frame 1, a start switch 2, a clamp switch 3, a control box 4, a rotating motor 5, a connecting rod 6, a support rod 7, a clamping device 8, a ring frame 9, a moving rod 11, and a triangular block 12 , clamping block 121, grinding rod 13 and grinding block 14, start switch 2 and clamping switch 3 are installed on the left side of the inner bottom wall of the fixed frame 1, the starting switch 2 is located on the left side of the clamping switch 3, the inner bottom of the fixed frame 1 A control box 4 is installed in the middle of the wall, and the control box 4 includes a switching power supply, a power module and a control module. A rotating motor 5 is installed on the left side of the inner bottom wall of the fixed frame 1. The rotating motor 5 is located on the left side of the start switch 2. The rotating motor 5 The left and right sides of the output shaft of the output shaft...

Embodiment 3

[0024] A workpiece grinding and polishing robot, such as Figure 1-3As shown, it includes a fixed frame 1, a start switch 2, a clamp switch 3, a control box 4, a rotating motor 5, a connecting rod 6, a support rod 7, a clamping device 8, a ring frame 9, a moving rod 11, and a triangular block 12 , clamping block 121, grinding rod 13 and grinding block 14, start switch 2 and clamping switch 3 are installed on the left side of the inner bottom wall of the fixed frame 1, the starting switch 2 is located on the left side of the clamping switch 3, the inner bottom of the fixed frame 1 A control box 4 is installed in the middle of the wall, and the control box 4 includes a switching power supply, a power module and a control module. A rotating motor 5 is installed on the left side of the inner bottom wall of the fixed frame 1. The rotating motor 5 is located on the left side of the start switch 2. The rotating motor 5 The left and right sides of the output shaft of the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com