Multi-layer degradation film

A technology of degrading film and degrading film, applied in the field of multi-layer degrading degradable film, can solve the problems of difficult operation and difficult control of degradation time, and achieve the effect of preventing oxidative decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

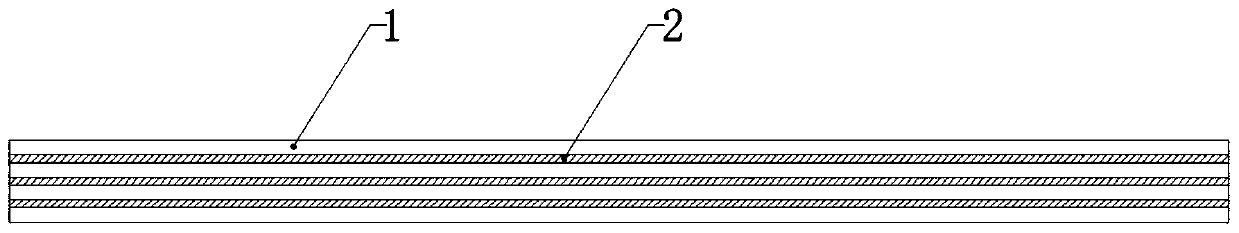

[0020] A multi-layer degradable degradable film, the degradable film is divided into multiple layers of degradable film 1 from top to bottom, and an isolation film 2 is arranged between any two layers of degradable film 1, and the isolation film 2 is used for In order to isolate each layer of degradable film 1, each layer of degradable film 1 can be degraded separately.

[0021] Preferably, any one of the degradable films 1 is a single-layer membranous structure, the thickness of the degraded film 1 is 0.01mm, and the water vapor transmission rate of the degraded film 1 is ≤0.5g / (m 2 .24h).

[0022] Preferably, any of the degradable films 1 is a polyethylene film with biodegradable or thermo-oxidative degradation performance, and the degradation time is 3 months.

[0023] Preferably, any of the isolation membranes 2 is a single-layer film structure, the thickness of the isolation membrane 2 is 0.03mm, and the oxygen transmission rate of the isolation membrane 2 is ≤ 1cm 3 / (...

Embodiment 2

[0028] A multi-layer degradable degradable film, the degradable film is divided into multiple layers of degradable film 1 from top to bottom, and an isolation film 2 is arranged between any two layers of degradable film 1, and the isolation film 2 is used for In order to isolate each layer of degradable film 1, each layer of degradable film 1 can be degraded separately.

[0029] Preferably, any one of the degradable films 1 is a single-layer film structure, the thickness of the degraded film 1 is 0.05mm, and the water vapor transmission rate of the degraded film 1≤0.5g / (m 2 .24h). .

[0030] Preferably, any of the degradable films 1 is a polyethylene film with biodegradable or thermo-oxidative degradation properties, and the degradation time is 9 months.

[0031] Preferably, any of the isolation membranes 2 is a single-layer film structure, the thickness of the isolation membrane 2 is 0.01mm, and the oxygen transmission rate of the isolation membrane 2 is ≤ 1cm 3 / (m 2 .24...

Embodiment 3

[0036] A multi-layer degradable degradable film, the degradable film is divided into multiple layers of degradable film 1 from top to bottom, and an isolation film 2 is arranged between any two layers of degradable film 1, and the isolation film 2 is used for In order to isolate each layer of degradable film 1, each layer of degradable film 1 can be degraded separately.

[0037] Preferably, any one of the degradable films 1 is a single-layer membranous structure, the thickness of the degraded film 1 is 0.03mm, and the water vapor transmission rate of the degraded film 1 is ≤0.5g / (m 2 .24h).

[0038] Preferably, any one of the degradable films 1 is a polyethylene film with biodegradable or thermo-oxidative degradation performance, and the degradation time is 6 months.

[0039] Preferably, any of the isolation membranes 2 is a single-layer film structure, the thickness of the isolation membrane 2 is 0.05mm, and the oxygen transmission rate of the isolation membrane 2 is ≤ 1cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com