Frame-shaped truss wing beam dual-beam variable pitch single-film flow-converging wing surface flapping wing

A technology of wing beams and trusses, applied in the field of aircraft, can solve the problems of unfavorable flapping wing flight, heavy weight, etc., and achieve the effect of simple conversion of pitch unequal distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be further illustrated (described) below in conjunction with the accompanying drawings.

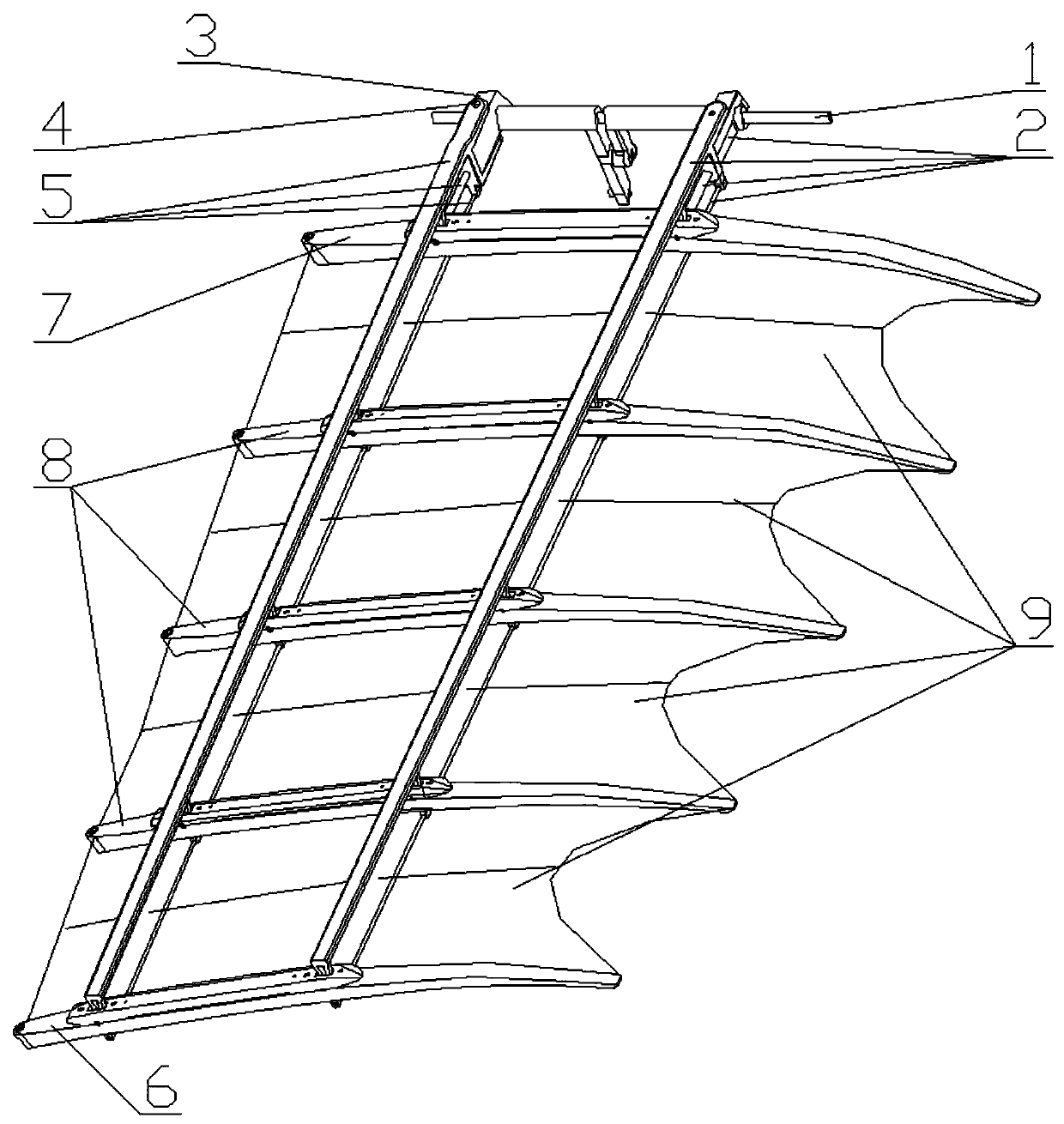

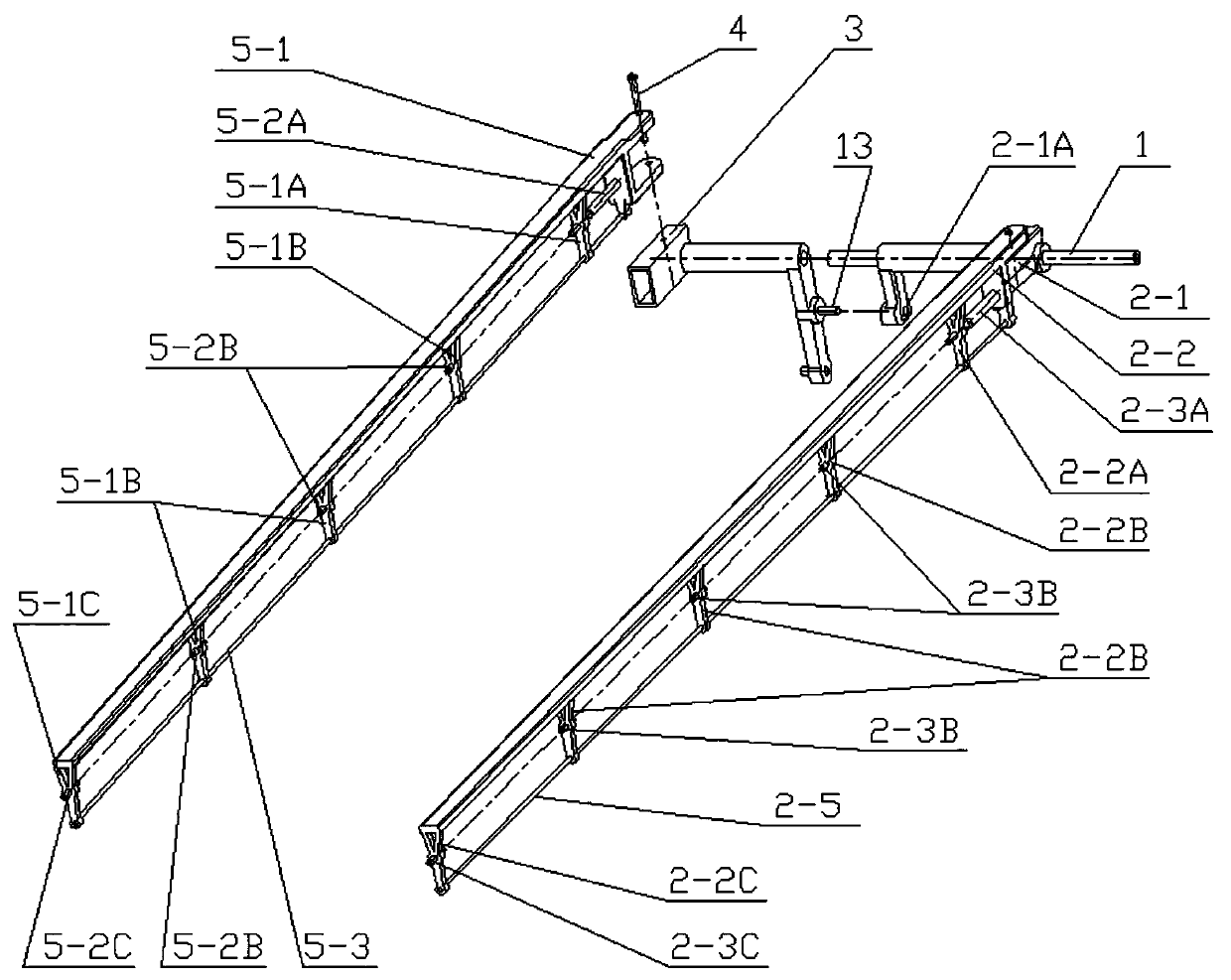

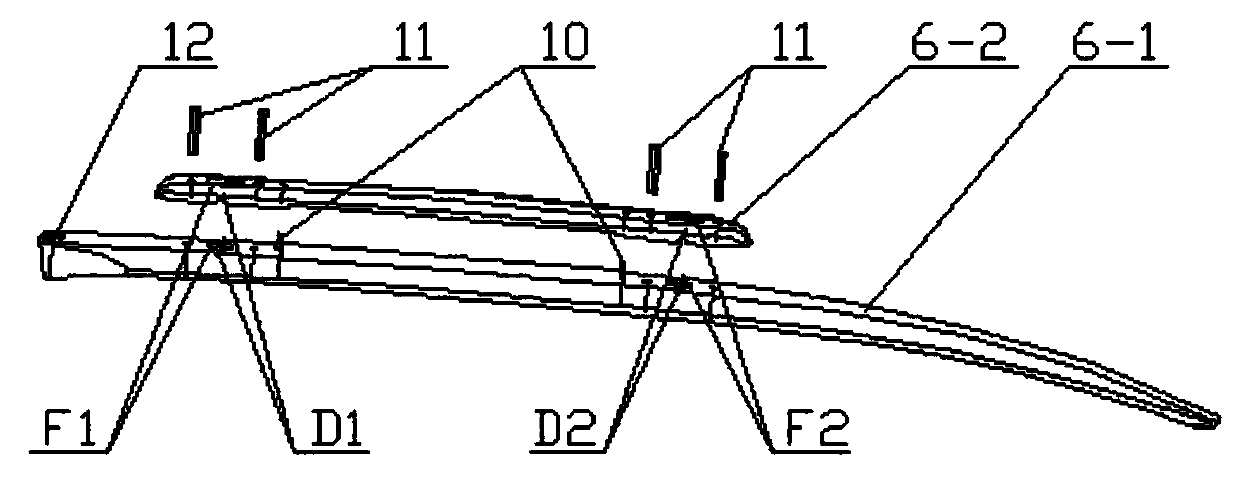

[0033] Frame-shaped truss spar double-girder variable-pitch single-membrane converging airfoil fluttering wing, including the flapping wing main shaft (1); bearing truss spar components (2), floating spar seat (3), pin shaft (4), floating Truss spar parts (5), wing end rib frames (6), wing root rib frames (7), spacer rib frames (8), single-membrane confluence airfoil (9);

[0034] The load-bearing truss spar part (2) includes a load-bearing spar seat (2-1), a load-bearing truss spar (2-2), a load-bearing beam mandrel root section (2-3A), and a load-bearing beam mandrel (2-3A). 3B), the end section of the load-bearing beam mandrel (2-3C), the lower truss (2-4), each piece is assembled into an integral frame-shaped truss firmware; the load-bearing truss wing beam (2-2) is provided with comb teeth type struts (2-2A), the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com