Installation structure of horizontal wrapping machine push plate driving oil cylinders and push plate driving device

A technology for driving oil cylinders and installation structures, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of the overall length of the main engine becoming longer, increasing the cost of use, uneven force, etc., to improve service life, save costs, The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. the embodiment.

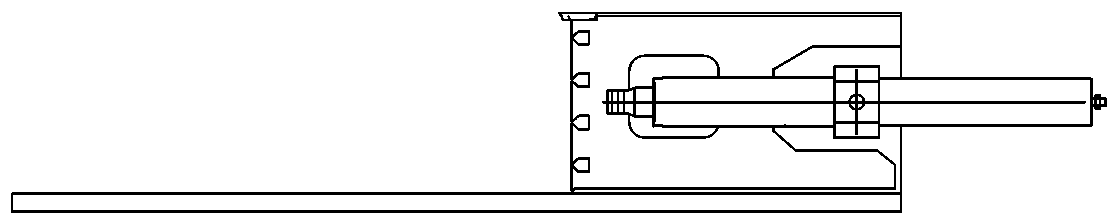

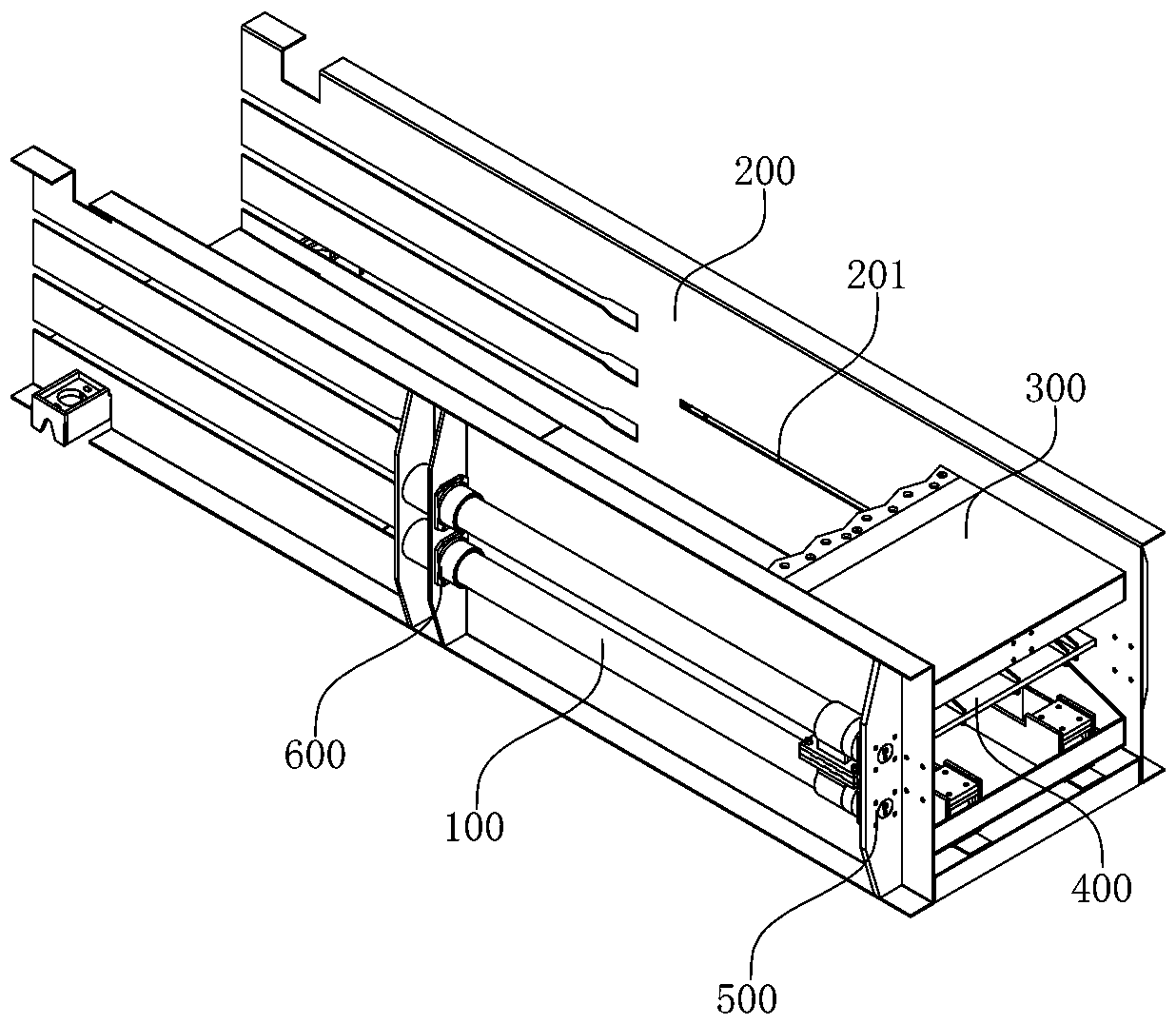

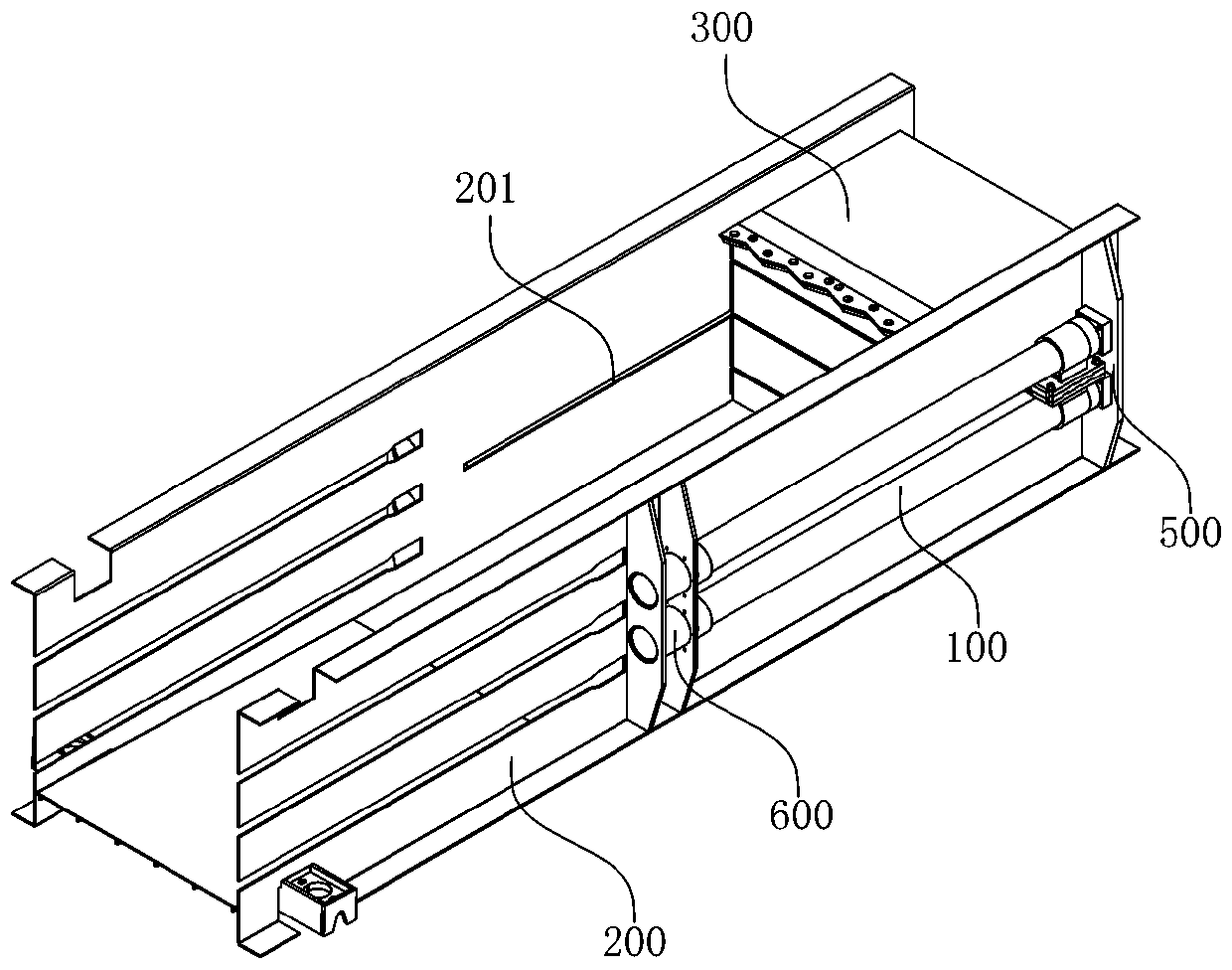

[0041] Such as Figure 2-Figure 13 , an installation structure for a push plate drive cylinder of a horizontal baler, which is arranged between the box bodies 200 on both sides and the push plate 300, including a push plate drive cylinder 100, a push plate drive plate 400, a fixing unit 500 and a guide unit 600 , multiple groups of push plate drive cylinders 100 are arranged symmetrically on both sides of the box body 200; the push plate drive plate 400 is arranged at the rear of the push plate 300; The end of 102 is fixedly arranged on the fixing unit 500 ; the guide unit 600 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com