A chemical safe shipping equipment

A safe and chemical technology, applied in the field of chemicals, can solve the problems of occupying ground space, hindering workers' work, wasting labor, etc., and achieve the effects of saving resources, improving work efficiency, and facilitating cooling treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

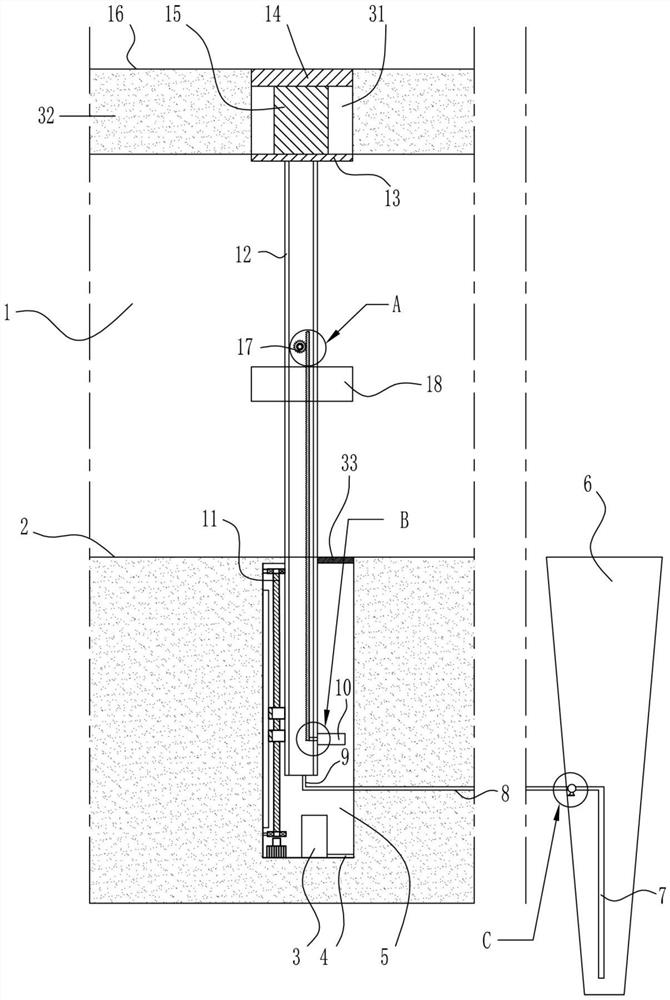

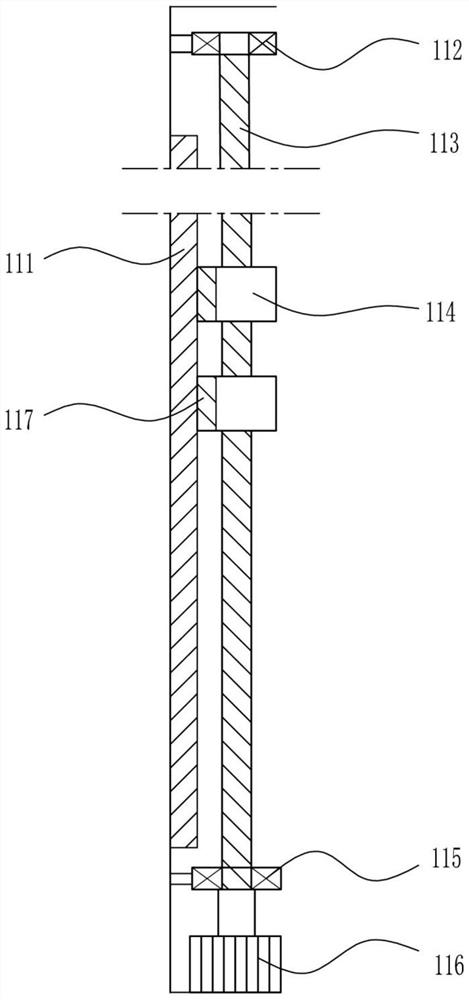

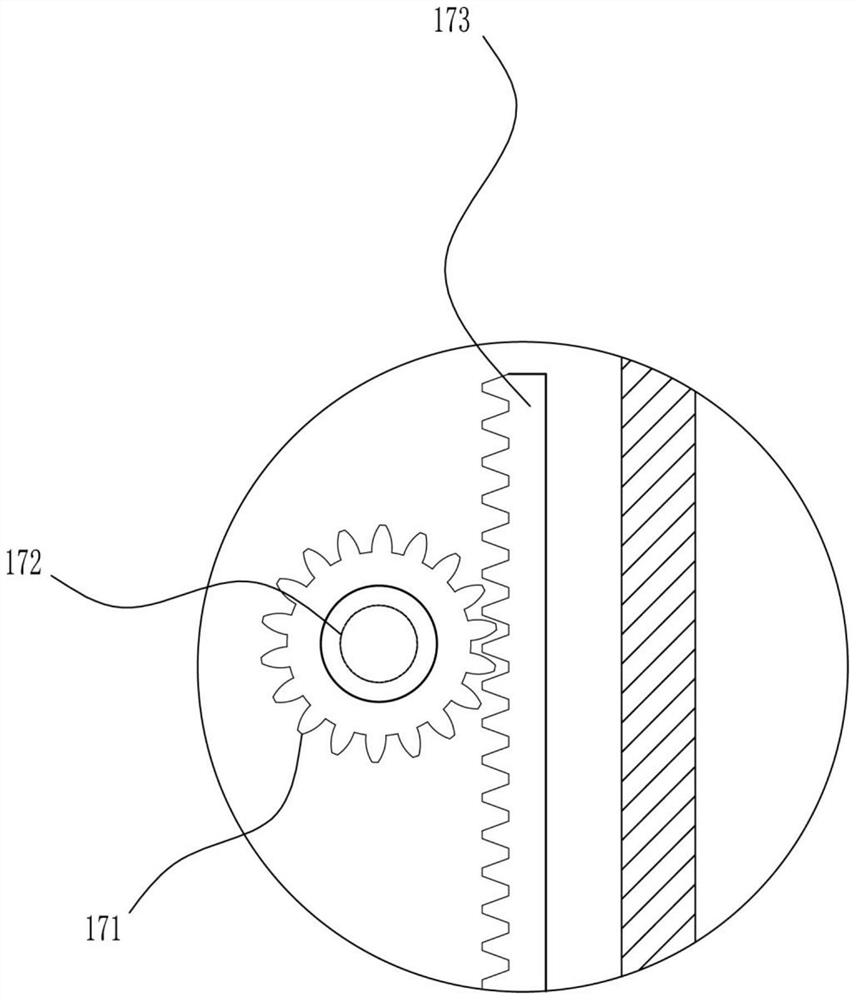

[0034] A chemical-safe handling facility such as Figure 1-12 As shown, it includes a water tank 3, a first water pipe 4, a second water pipe 7, a third water pipe 8, a flexible pipe 9, a loading plate 10, a lifting device 11, a hollow column 12, a lighting lamp 13, a top plate 14, and a connecting column 15 , lifting mechanism 17, conveying body 18, small bearing 22, driving lever 23, vertical rod 25, nozzle 26, water pump 30, cover plate 33 and connecting slide bar 34; underground workshop 1 is arranged below the ground surface 16, underground workshop 1 The roof body 32 of the workshop is connected with the ground surface 16, and the roof body 32 of the workshop is provided with a communication hole 31 along the vertical direction; the workshop floor 2 of the underground workshop 1 is provided with an installation groove 5, and the installation groove 5 is located at the front of the communication hole 31. Below, a cover plate 33 is fixedly connected to one side of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com