Integrated optical temperature measurement sensing chip, optical temperature measurement sensing equipment and temperature measurement method

A technology integrating optics and sensor chips, applied in the field of precision sensing, can solve the problem of inability to accurately measure the temperature change of integrated optical devices, and achieve the effects of high precision, reduced manufacturing costs, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

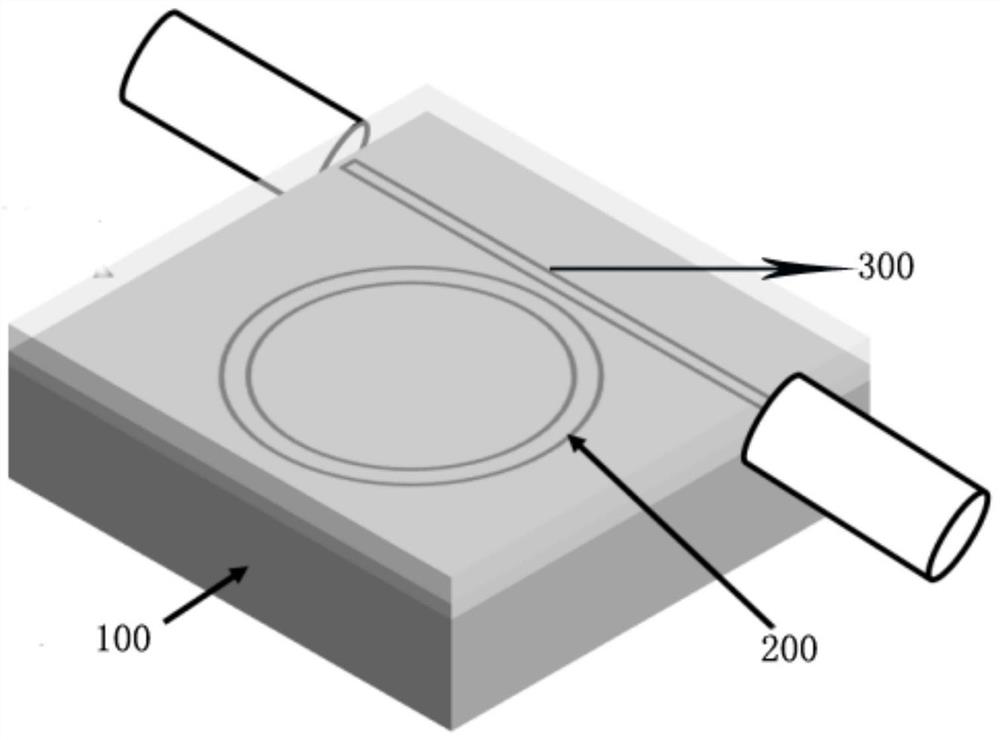

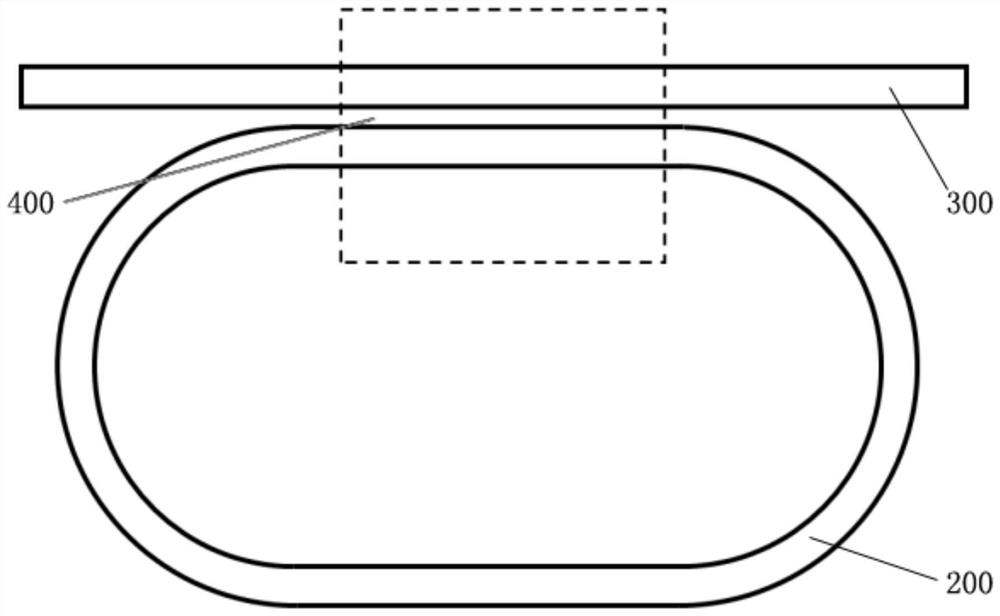

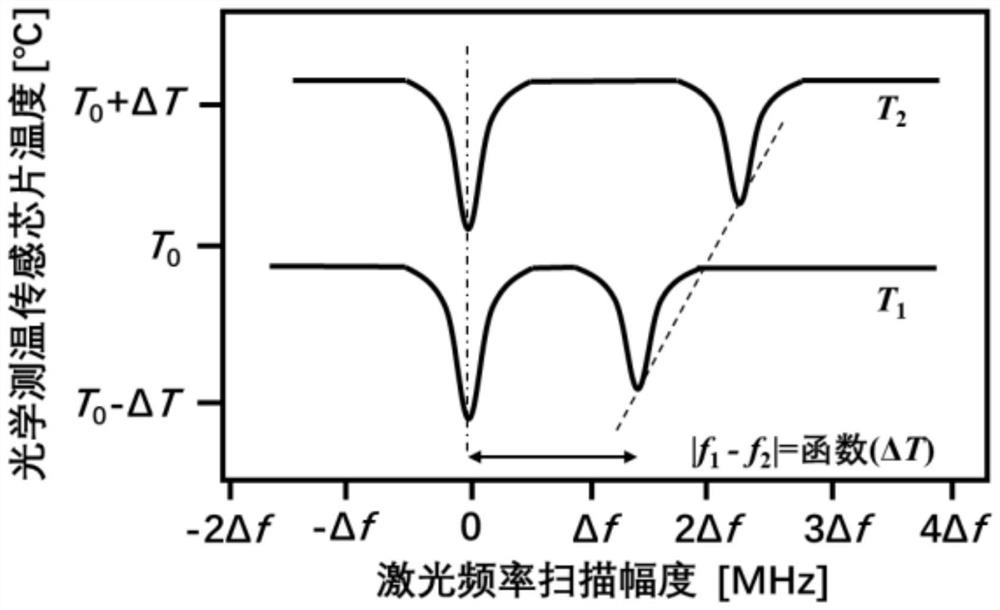

[0026] The optical method is used to measure temperature without introducing additional electronic devices, and will not affect the optical transmission, and its measurement accuracy is also higher than that of thermistor devices. The optical temperature measurement method based on two orthogonal polarization modes uses the difference of the thermo-optic coefficients of the optical mode fields of the two orthogonal polarization directions in the optical device, and reads the optical mode fields of the two orthogonal polarization directions in the optical device. The change of the transmission property in the device can reverse the change of the temperature in the device, so as to realize the accurate measurement of the temperature change. This method has been applied in bench-top Fabry Perot resonators and whispering gallery resonators. However, these optical resonators have large volumes, and the manufacturing process is not compatible with semiconductor processes, so they can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com