Intermittent juglans sigillata crushing and shell-kernel separating device and juglans sigillata oil extracting technology

A technology for separating kernels and shells and iron walnuts, which is applied in the fields of fat oil/fat production, fat oil/fat refining, and fat generation, which can solve the problems of high labor costs, high energy consumption for heating and boiling, and low production efficiency, and achieve a reduction in content The effect of benevolence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

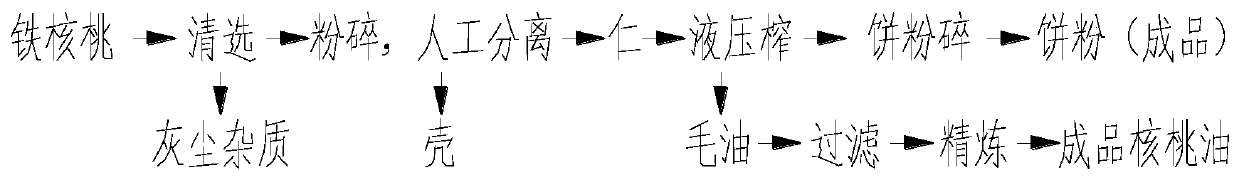

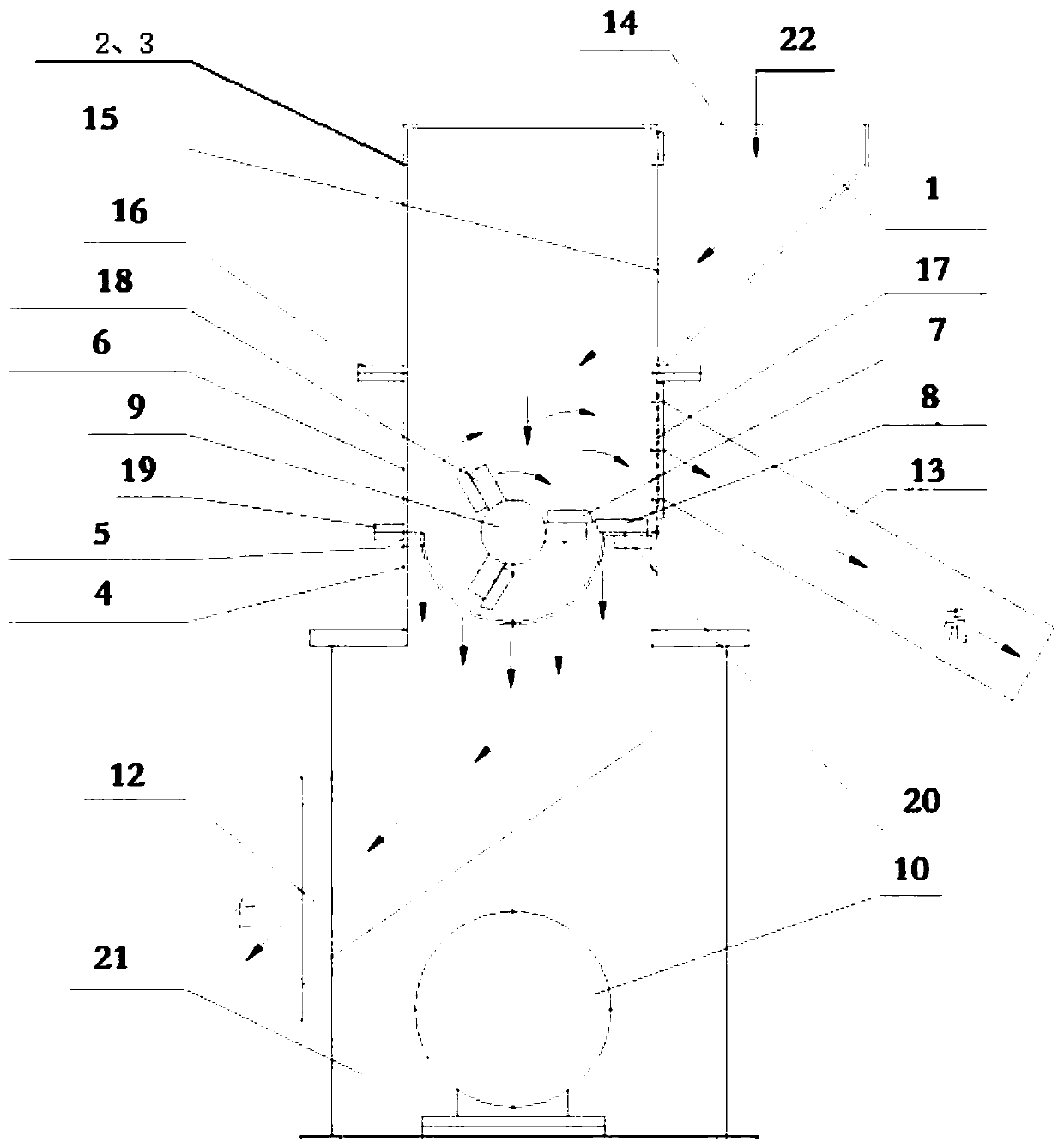

[0061] A kind of oil extraction method of iron walnut, such as Figure 4 shown, including the following steps:

[0062] S1. Cleaning: Iron walnut raw materials contain dust, light impurities, heavy impurities, large impurities, and small impurities, and the impurities need to be cleaned before crushing; use a suction vibrating screen to remove heavy impurities, large impurities, and small impurities, and use a cyclone The dust collector removes dust and light impurities;

[0063] S2. Measuring and weighing: the iron walnuts are measured by the volumetric automatic feeding device and then fall into the iron walnut crushing kernel shell separator. The feeding amount of the iron walnut crushing kernel shell separator is determined each time.

[0064]S3, crushing and shelling: after the iron walnut is measured, it falls into the iron walnut crushing kernel shell separation device for crushing, and the shell and kernel are separated. While the iron walnut is being crushed, 65% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com