Production method of antibacterial blended yarn

A production method and blended yarn technology, which is applied in yarn, textiles and papermaking, etc., can solve problems such as poor cohesion, affecting yarn quality, and imperfect processing technology of graphene nylon fiber, etc., and achieve excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Take the preparation of graphene nylon / polyester blended yarn for Siro compact knitting with a blending ratio of 40 / 60 and a linear density of 14.8tex as an example:

[0016] (1) Selection of raw materials:

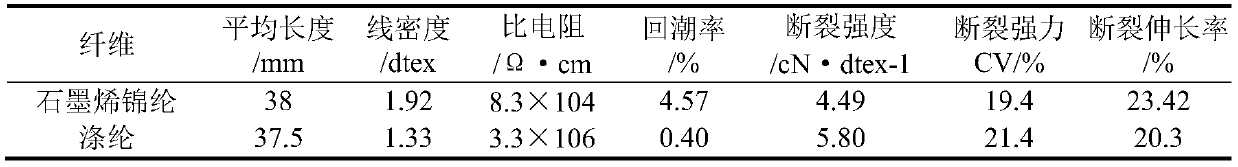

[0017] The basic performance indicators of the two fibers

[0018]

[0019] (2) Spinning process:

[0020] Polyester fiber: A002D type plucking machine → A035C type mixed cotton opener → FA106B type cotton opener → A092 type cotton feeder → A076F type lapping machine → FA231C type carding machine;

[0021] Graphene nylon fiber + polyester fiber: FA002C type catching machine → FA106A type cotton opener → FA035B type cotton mixing machine → FA161 type cotton feeder → A076E type lapping machine → FA201B type carding machine → JWF1310 type drawing frame;

[0022] Polyester raw sliver + graphene nylon / polyester pre-drawing: JWF1310 drawing frame (three lanes) → JWF1415 roving frame → EJM128K spinning frame

[0023] (3) Process parameter design:

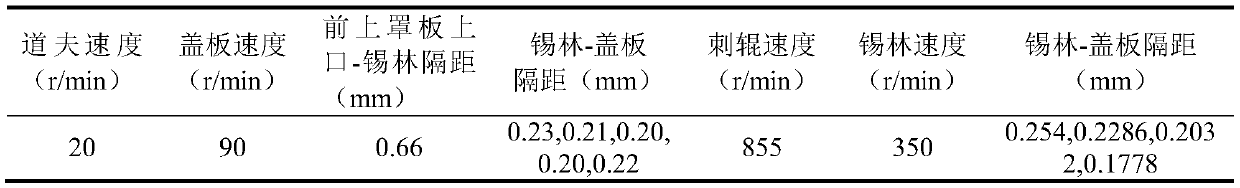

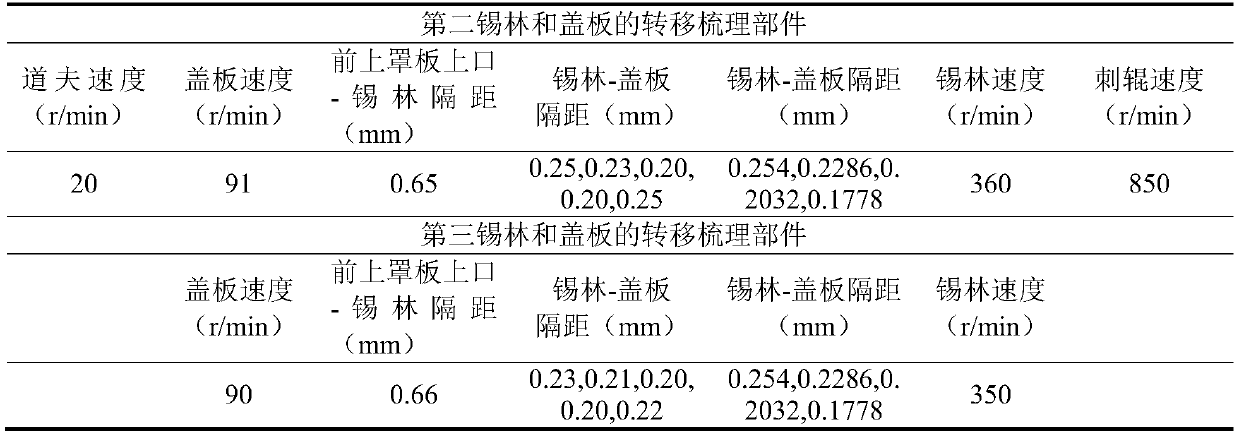

[0024] Polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com