Adjustable cloth dyeing machine nozzle

A cloth dyeing machine, adjustable technology, applied in the direction of spray/jet textile material processing, textile material processing equipment configuration, etc., can solve the problems of complex overall structure, high material cost, high equipment cost, etc., and achieve simple overall structure and low material cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

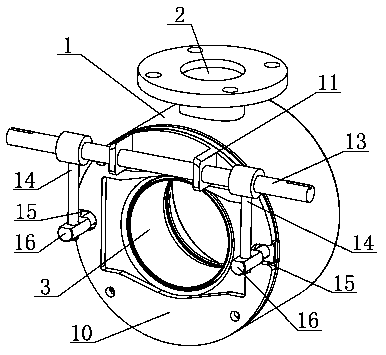

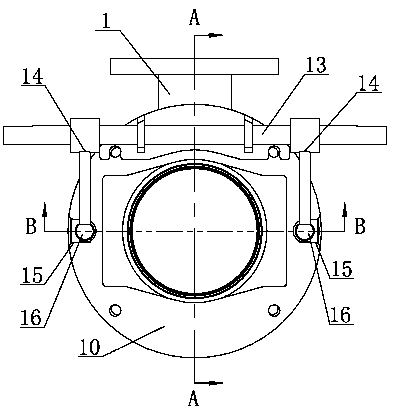

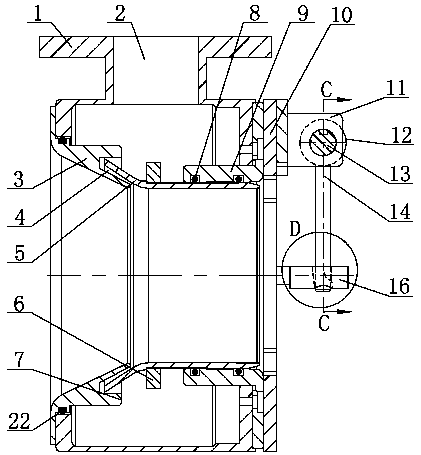

[0035] Such as figure 1 , figure 2 , image 3 As shown, the outer peripheral surface of the base 1 of the present invention protrudes and is provided with a water inlet 2, and the base 1 is provided with a trumpet-shaped outer spout 3 and an inner spout 5, and the bell mouth of the outer spout 3 and the inner spout 5 faces outwards, Such as image 3 As shown, the outer surface of the outer nozzle 3 protrudes toward the direction of the inner nozzle 5 with a circular guide ring 7, and a circle of grooves is formed between the guide ring 7 and the end of the outer nozzle 3 near the inner nozzle 5, and the inner The outer end of the nozzle 5 is located in the groove and there is an annular nozzle gap 4 between the groove and the outer nozzle 3 and the inner nozzle 5 are cloth guide channels; the dye flows in from the water inlet 2 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com