A protective structure for bridge abutments

A technology for protective structures and abutments, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as erosion of abutments and low strength of abutments, and achieve the effect of prolonging service life and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

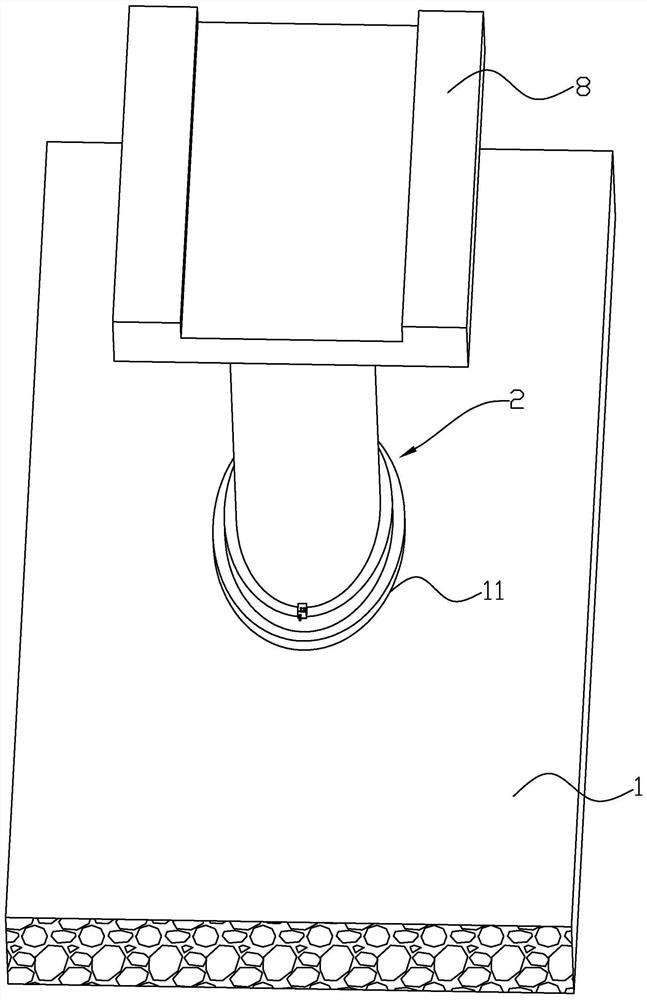

[0035] Embodiment: a kind of protective structure for abutment, such as figure 1 As shown, a pile hole 11 opened in the soil layer 1 is included, and a waterproof device 2 is arranged in the pile hole 11 .

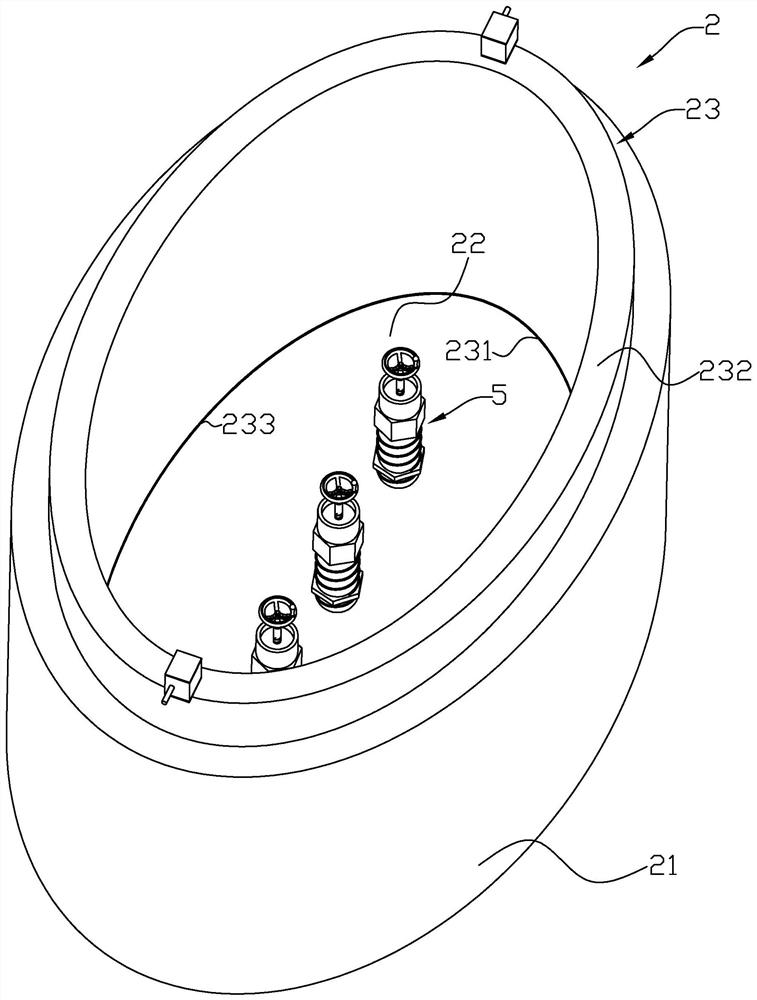

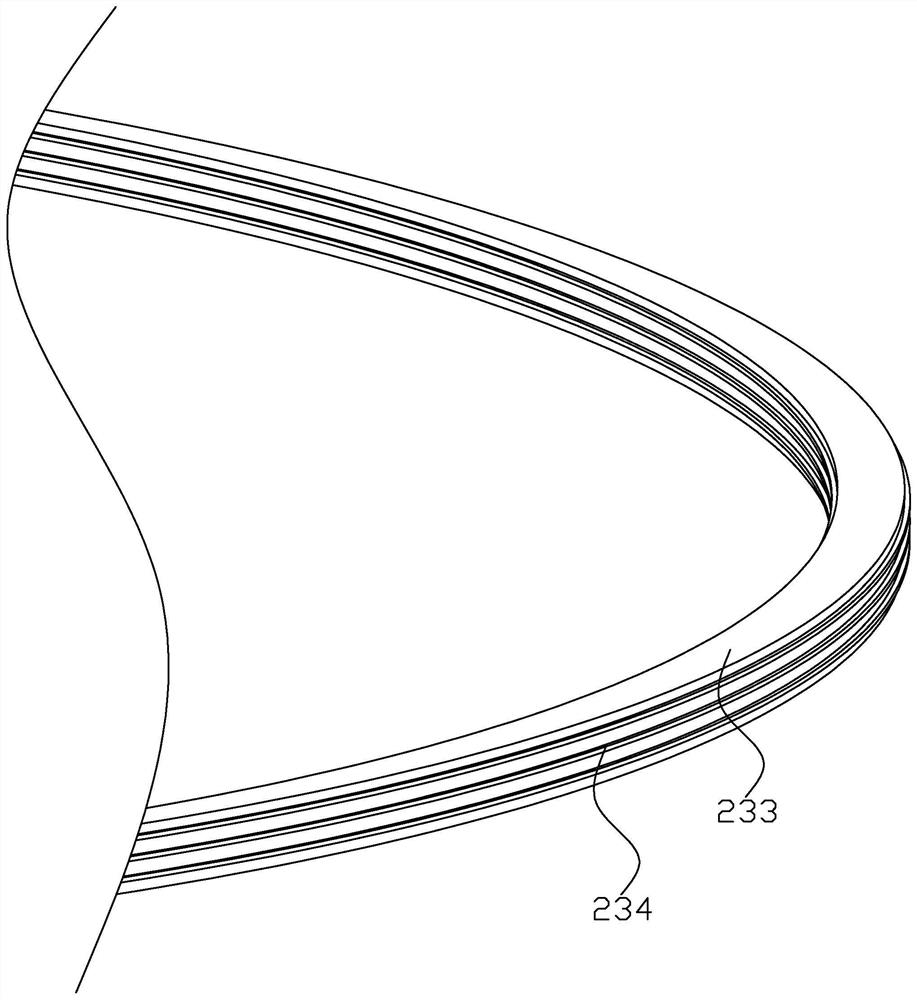

[0036] Such as figure 1 and figure 2 As shown, the waterproof device 2 includes a concrete layer 21 laid in the pile hole 11, an acid-resistant steel plate 22 installed at the bottom of the concrete layer 21, and multiple sets of fixings installed on the acid-resistant steel plate 22 for fixing the acid-resistant steel plate 22 to the soil layer 1. Mechanism 5 and the waterproof assembly 23 arranged on the outer periphery of the acid-resistant steel plate 22; concrete preservatives can be added to the concrete layer 21, thereby reducing the corrosion rate of the concrete. When the concrete layer 21 is corroded, the concrete layer 21 can be recast, because the concrete layer The volume of 21 is relatively small, so compared to repairing the abutment 8, it is easier and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com