Concrete pouring hopper for building construction

A technology for building construction and concrete, which is applied in the processing of building materials, construction, building construction, etc. It can solve the problems of not being able to meet various building structures and poor adjustment performance, and achieve an increase in the scope of application, simple structure, and convenience. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

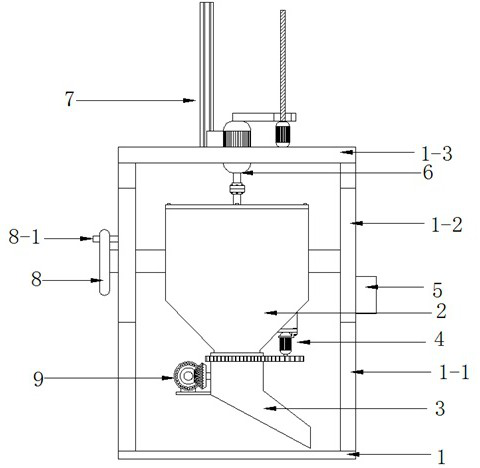

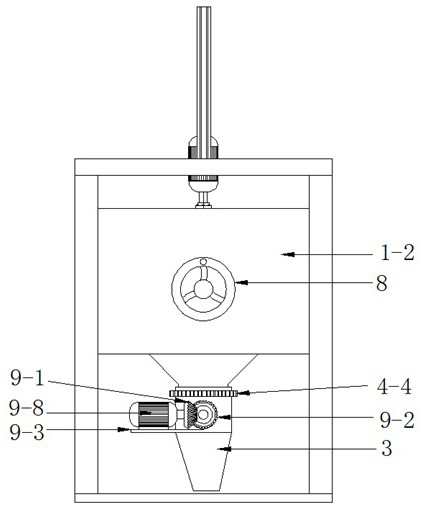

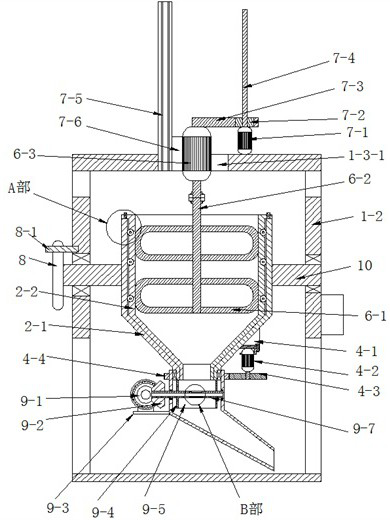

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] see as Figure 1-Figure 9 As shown, the technical solution adopted in this specific embodiment is: it includes a base 1, a column 1-1, a horizontal plate 1-2, a top plate 1-3, a hopper 2, a discharge pipe 3, a direction adjustment mechanism 4, and an electric control box 5. Stirring mechanism 6, lifting mechanism 7, rotating handle 8, quantitative adjustment mechanism 9, hopper rotating shaft 10; the four corners of the upper surface of the base 1 are welded and fixed with a column 1-1, and the top of the column 1-1 is connected to the top plate 1-3 The four corners are connected and fixed; among them, the horizontal plate 1-2 is welded and fixed between the front and rear columns 1-1 on the left and the front and rear on the right (the distance between the upper edge of the horizontal plate 1-2 and the top plate 1-3 The output end of the external concrete mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com