Method for manufacturing concrete by using building solid waste

A kind of waste concrete, concrete technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

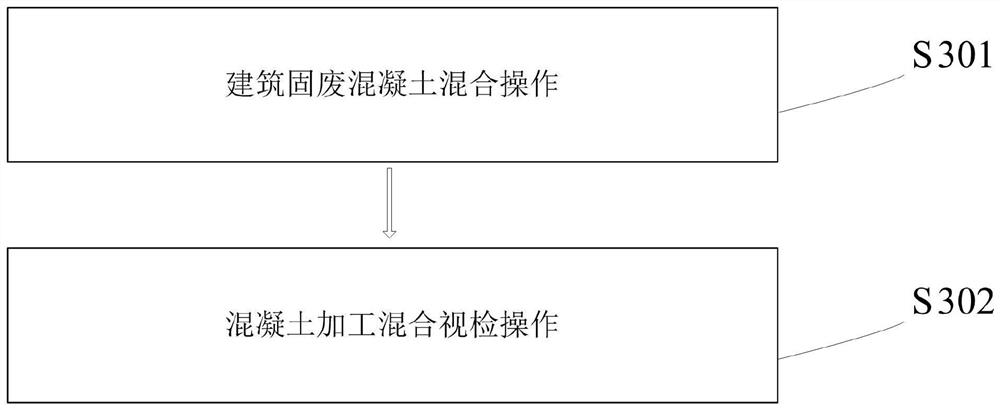

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] In the picture:

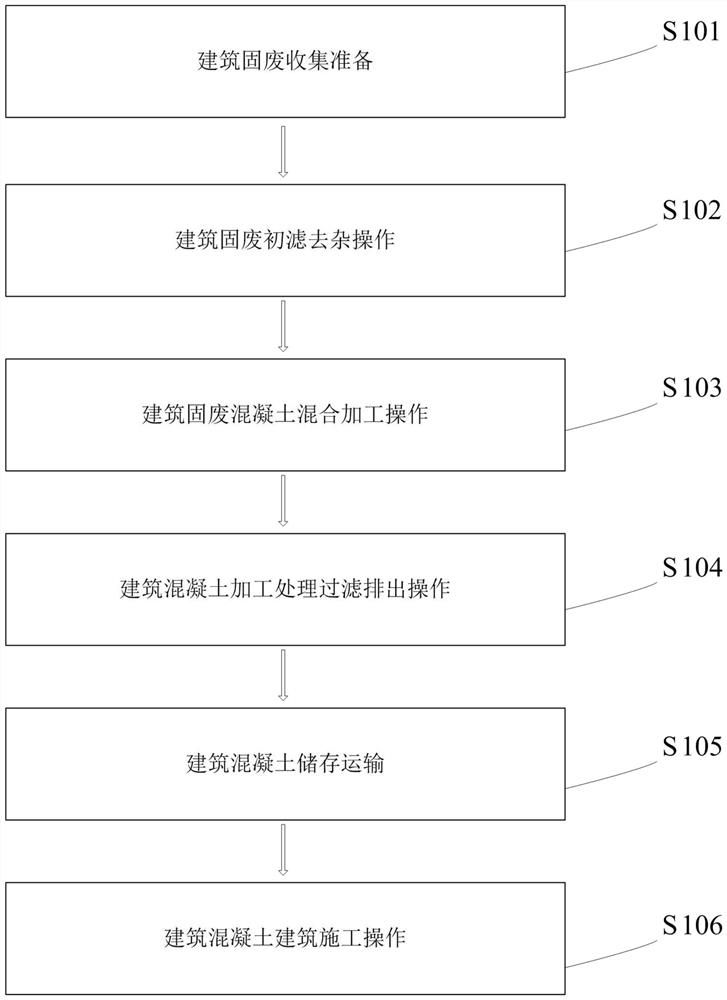

[0035] as attached figure 1 shown

[0036] A method for making concrete from construction solid waste specifically comprises the following steps:

[0037] S101: Construction solid waste collection preparation, transport and collect construction solid waste to a unified site through collection vehicles, pass manual preliminary inspection, and perform preliminary classification, and then perform subsequent processing operations, and prepare mixed soil for solid waste mixing Soil processing process;

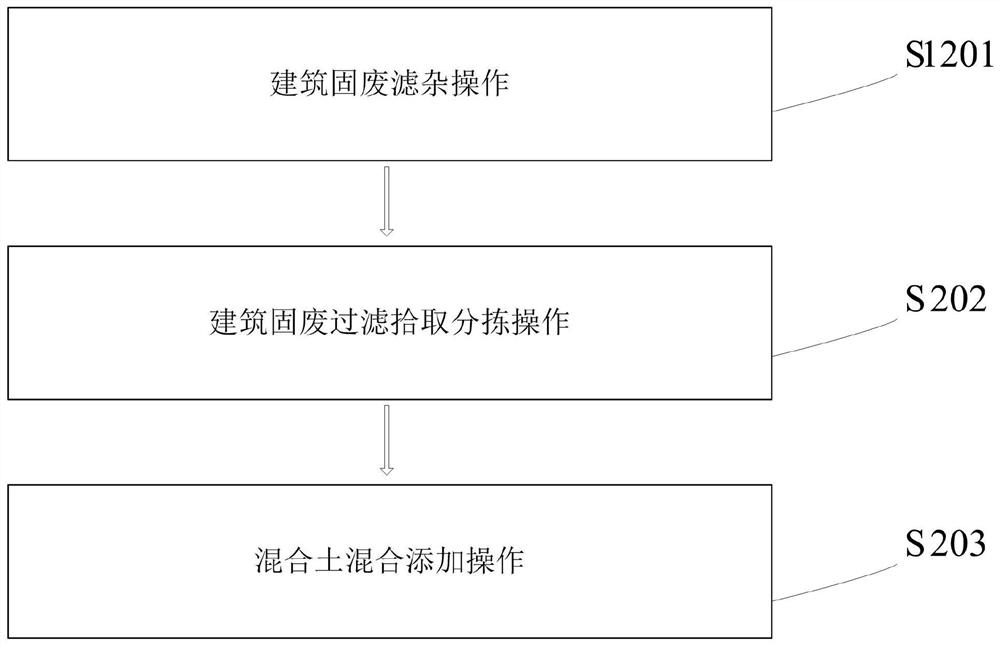

[0038] S102: Primary filtration of construction solid waste to remove miscellaneous figure 2 As shown, the specific operation includes the following steps:

[0039] S201: construction solid waste filtering operation, the construction solid waste is introduced through the hopper 7, and larger impurities are filtered through the filter miscellaneous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com