Construction process of high-strength beam columns coated with fast growing poplars out of thin-walled cold-formed steel

A technology of cold-formed thin-walled section steel and construction technology, applied in wood processing appliances, wood treatment, impregnated wood, etc., can solve the problem that fast-growing poplar cannot be applied to building beams and columns, and achieve the effect of meeting building needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

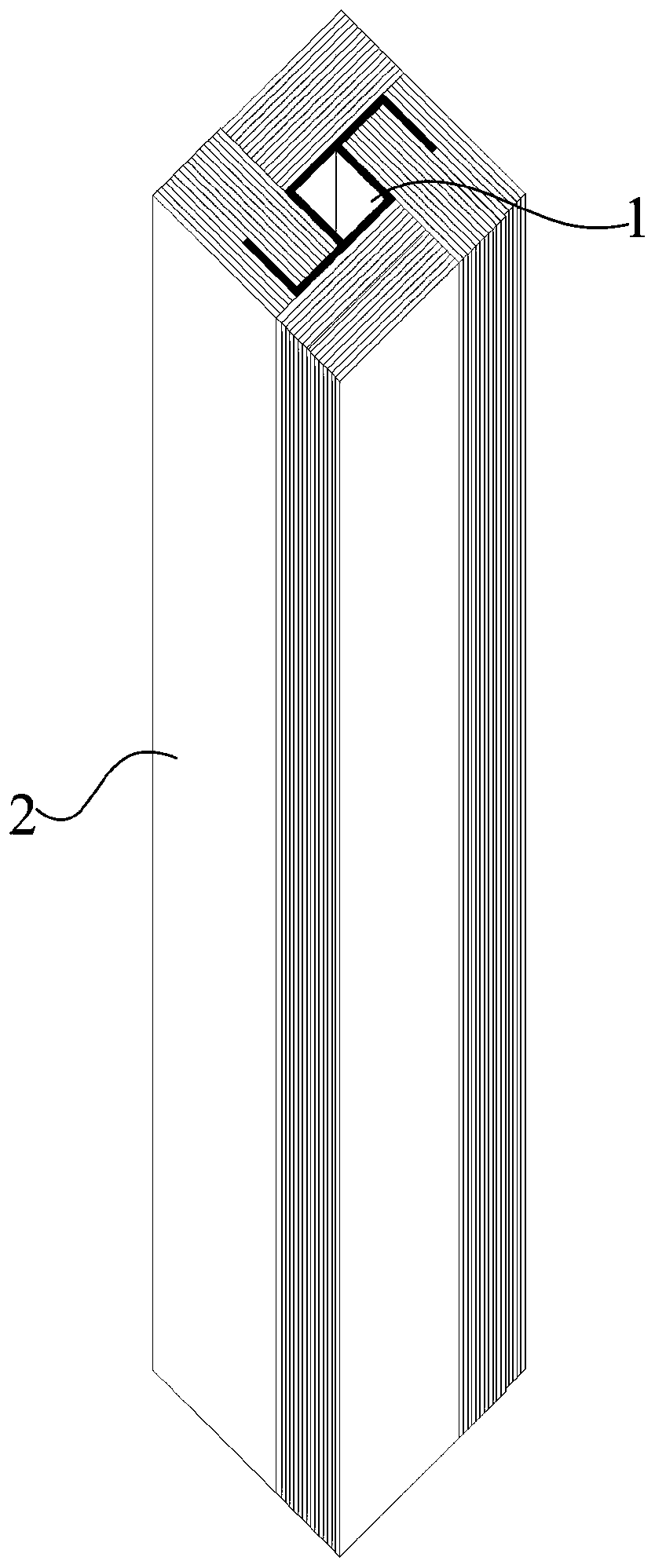

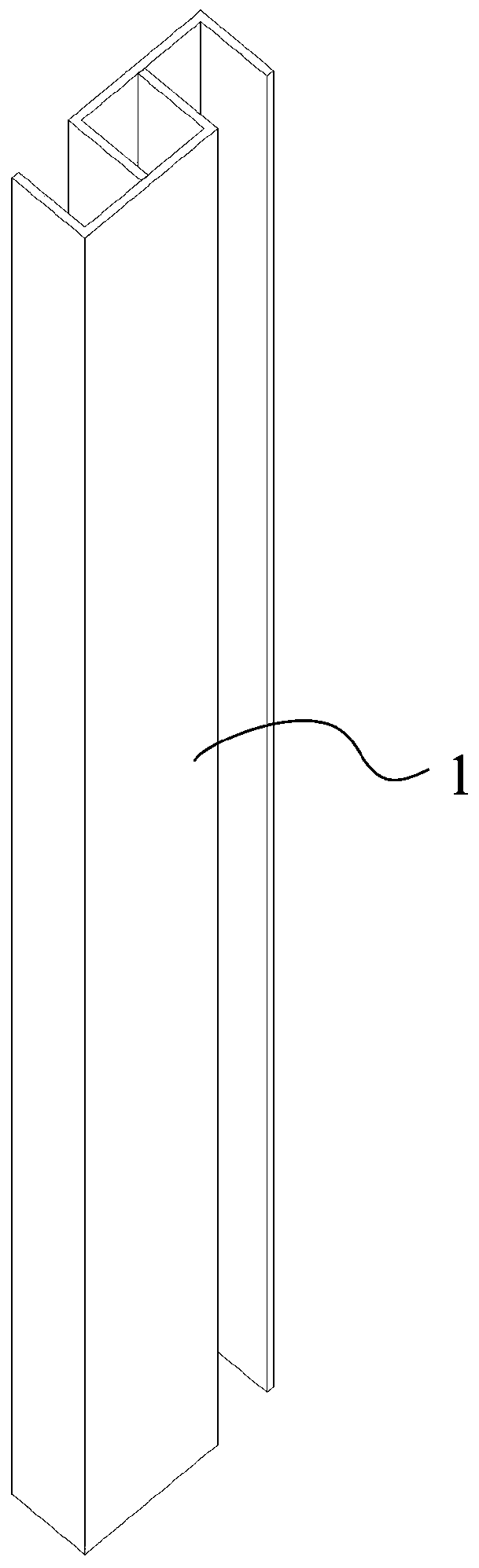

[0028] Example 1, such as figure 1 , figure 2 As shown, this embodiment provides a cold-formed thin-walled steel outsourcing fast-growing poplar high-strength beam column

[0029] First of all, material selection, considering that the modified fast-growing poplar wood provided in this embodiment is used in construction, so in this implementation, the selection of materials also plays a vital role in the strength of the later finished product. First, select the fast-growing poplar Poplar logs with a straight trunk and a diameter of about 20cm are placed in a cool place. The main reason for choosing poplar with a straight trunk is that it is more convenient to process. The main reason for choosing a log with a diameter of about 20cm Considering the construction needs of this embodiment, the main purpose of placing it in a cool place is to avoid exposure to the sun, which will cause cracking of the poplar and affect its strength.

[0030] Then, cut the selected fast-growing po...

Embodiment 2

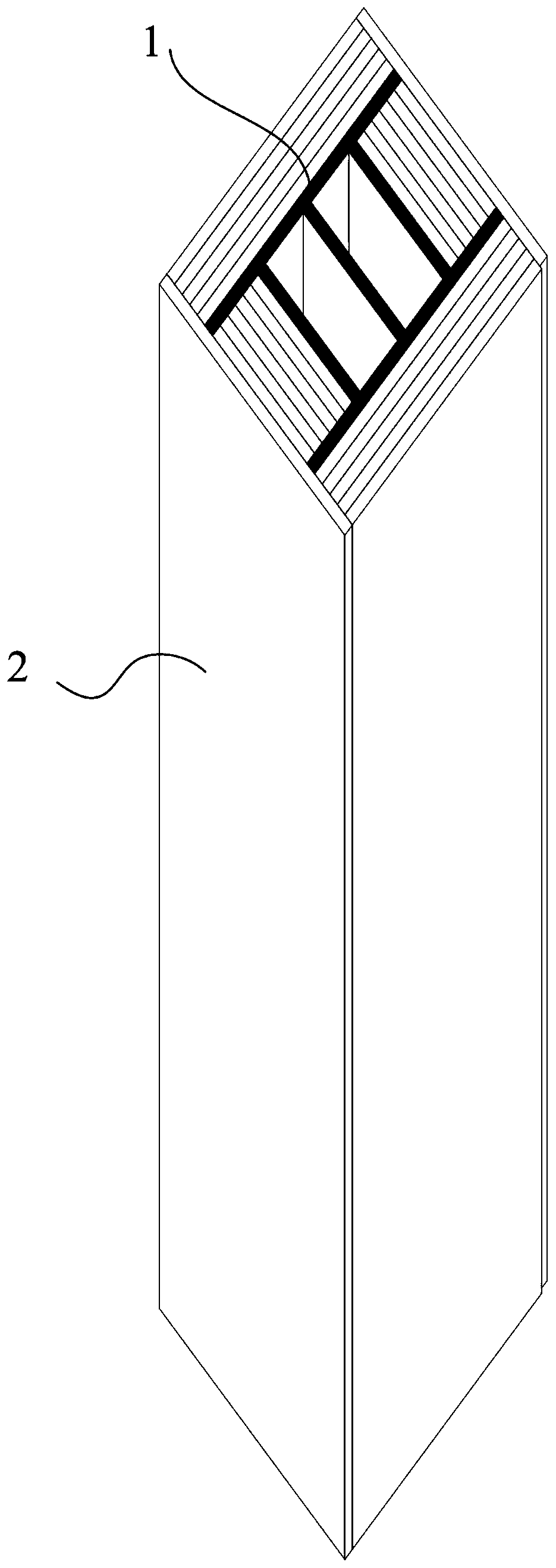

[0040] Example 2, such as image 3 As shown, this embodiment provides a cold-formed thin-walled steel outsourcing fast-growing poplar high-strength beam column

[0041] Compared with Example 1, this embodiment mainly lies in that the cold-formed thin-walled steel used is different. In this embodiment, the I-shaped (H-shaped) cold-formed thin-walled steel is used. In this embodiment, by The I-shaped cold-formed thin wall is welded with two steel plates, so that a square is formed between the I-shaped cold-formed thin wall and the two steel plates. Due to the existence of the web of the I-shaped cold-formed thin wall, the overall shape Type setting, the purpose of this setting is to ensure the strength of the middle of the entire beam and column.

[0042] The method of laying is the same as that of the embodiment, one layer is 10mm thick, and the other layer is 5mm thick, but the widths are different, and finally the overall cross-section can be designed to be square.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com