Automobile anti-pinch strip

A technology of anti-clamping and clamping strips, which is applied in door/window fittings, buildings, wing leaf control mechanisms, etc., can solve the problem of limiting the degree of freedom in tailgate design and customer experience, limited use angles of anti-clamping strip sections, and lateral The bending arc is not large, and the anti-pinch effect is good, the anti-pinch is sensitive, and the effect of good adaptability is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

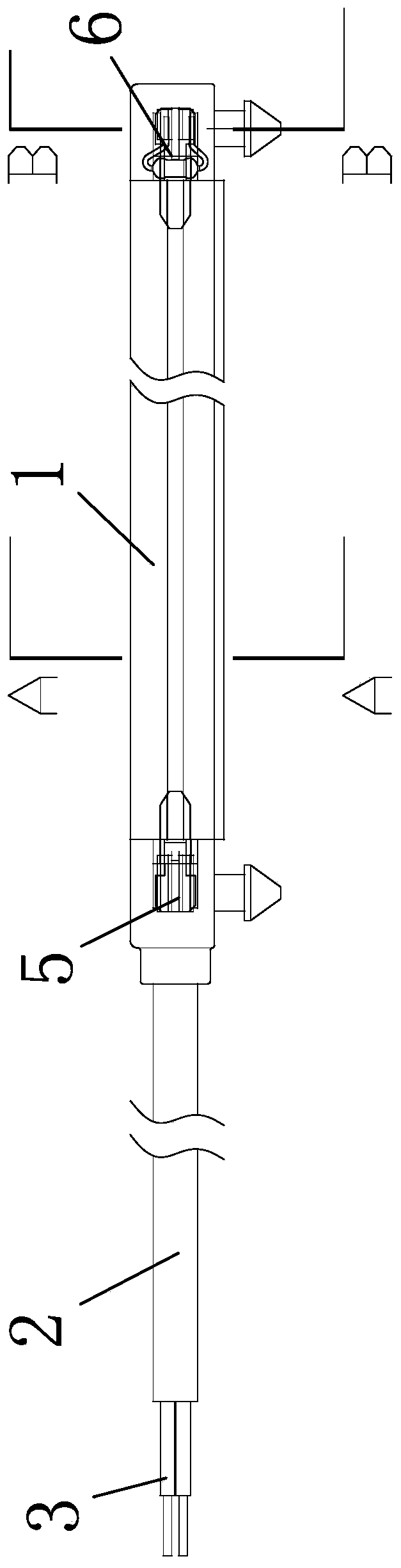

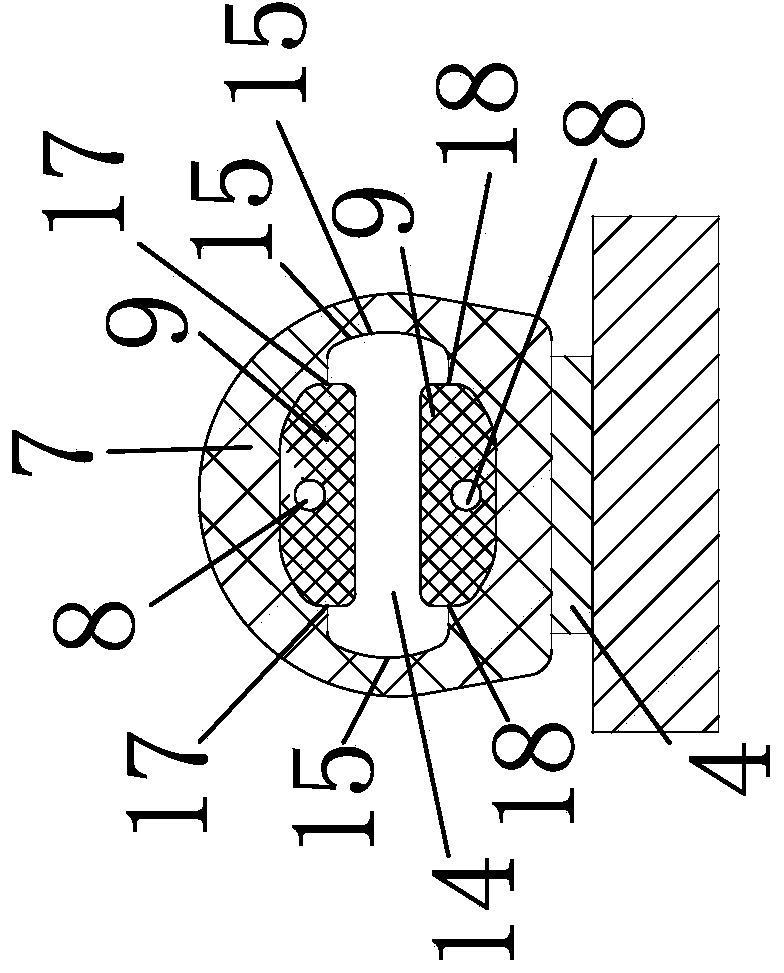

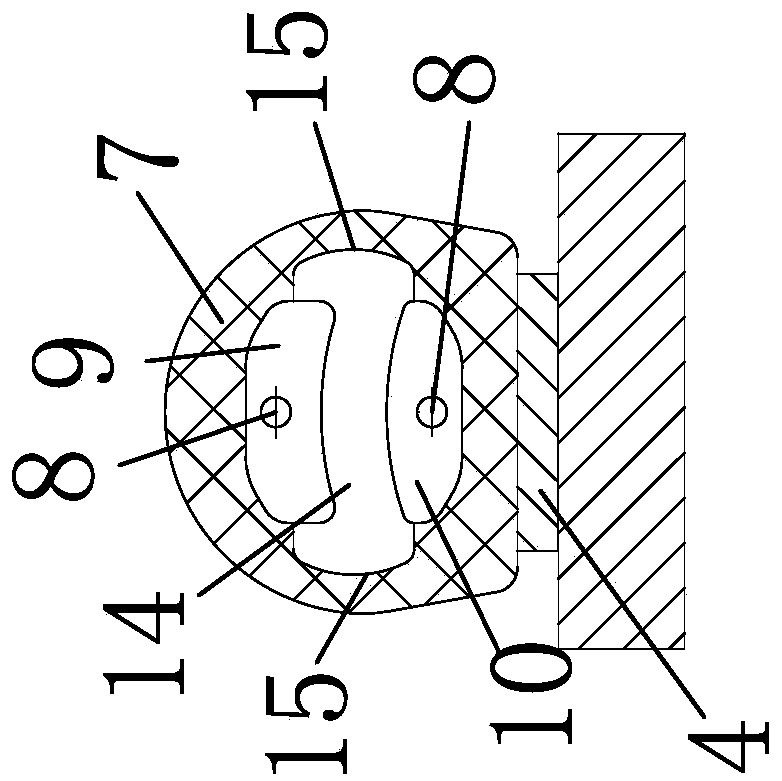

[0020] In the figure, anti-pinch strip body 1; sheath wire 2; conductive connector 3; adhesive tape 4; anti-pinch strip front end 5; anti-pinch strip end 6; insulating rubber 7; conductive wire 8; Conductive rubber 10; fixed resistance 11; insulating sheet 12; connecting sheet 13; middle cavity 14; lateral bending arc angle 15; contact resistance 16; upper end and upper conductive rubber contact point 17; lower end and lower conductive rubber contact point 18; Groove 19; plane 20; mushroom nail 21; barb shape 22.

[0021] Such as figure 1 As shown, the automobile anti-pinch strip includes an anti-pinch strip body 1, a sheath wire 2, a conductive connector 3, an adhesive tape 4, an anti-pinch strip front end 5 and an anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com