A kind of led module sealing process

A technology of LED modules and processes, applied in lighting and heating equipment, components of lighting devices, light sources, etc., can solve the problems of cumbersome installation steps and complex sealing structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

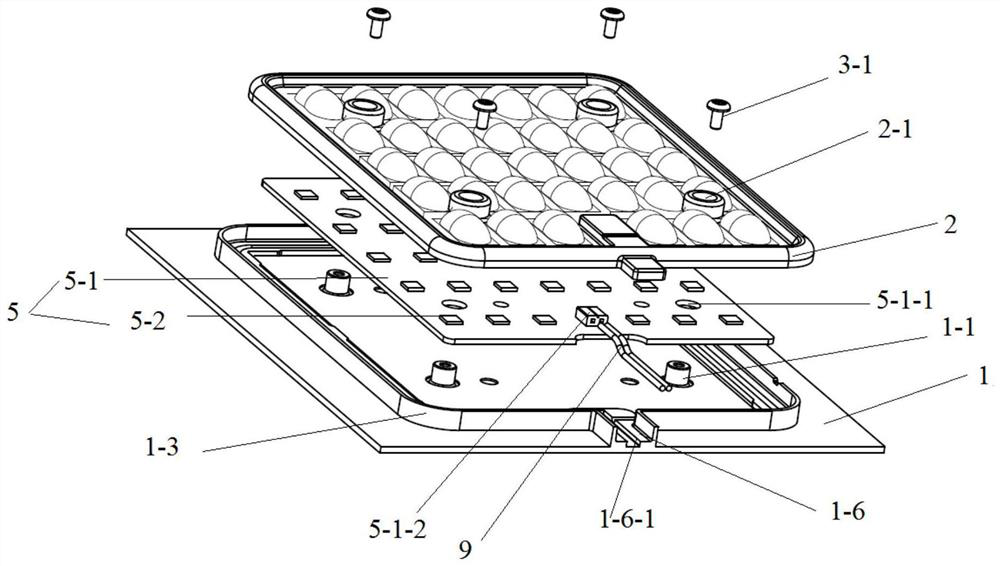

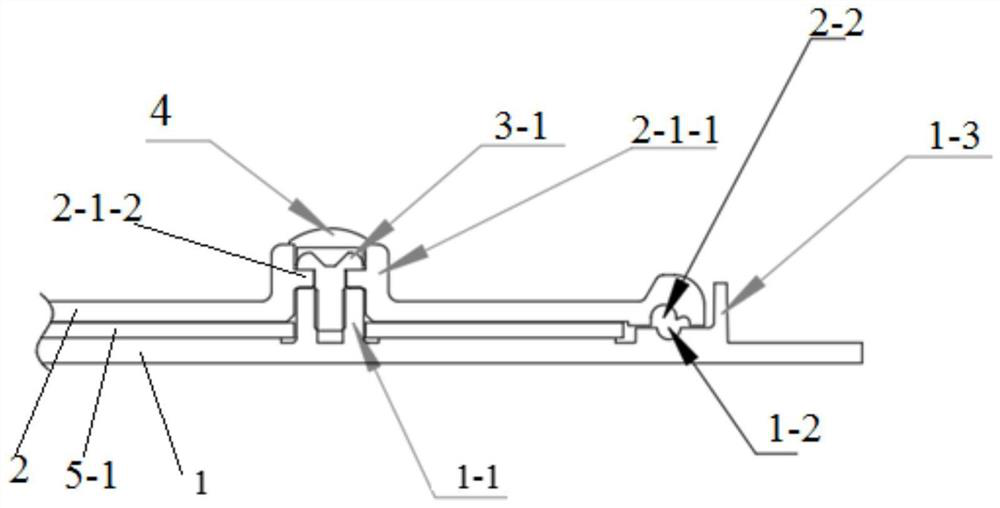

[0057] A kind of LED module sealing process, see Figure 1-Figure 2 , including the following steps:

[0058] (1) Forming the lamp housing, the lamp housing 1 is integrally formed with a screw column 1-1, the first glue groove 1-2; forming a lens 2, and the lens 2 is integrally formed with a through hole 2-1, a second Glue groove 2-2; Assemble the LED lamp bead 5-2, the wire 9 and the PCB board 5-1 with the round hole 5-1-1 to form the light source assembly 5; it should be understood that the screw column should be provided with a screw The hole is used to cooperate with the screw, and the screw hole can be punched on the screw column by machining;

[0059] (2) Apply a ring of sealant 4 evenly on the first glue groove 1-2 on the lamp housing 1 obtained in step (1); Apply a ring of sealant 4 evenly on the glue tank 2-2;

[0060] (3) Install the light source assembly 5 in step (1) on the lamp housing 1 processed in step (2), at this time, the circular hole 5-1-1 of the PCB bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com