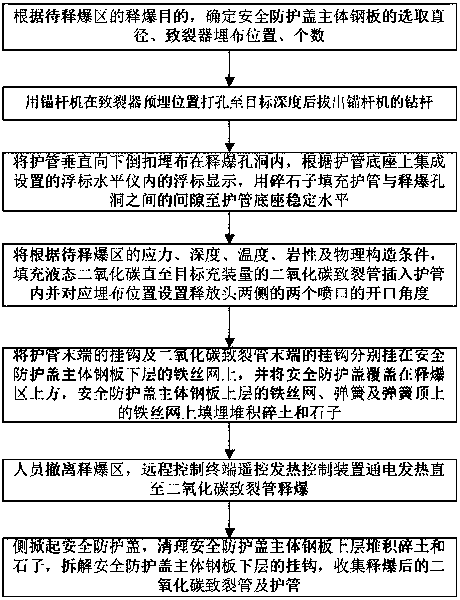

Carbon dioxide fracturing pipe explosion-release improving device and explosion-release method

A carbon dioxide and cracking tube technology, applied in the field of blasting, can solve the problems of wasting manpower and material resources, the tube body is absolutely vertical, etc., and achieve the effects of reducing quality, preventing random collision and sputtering, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

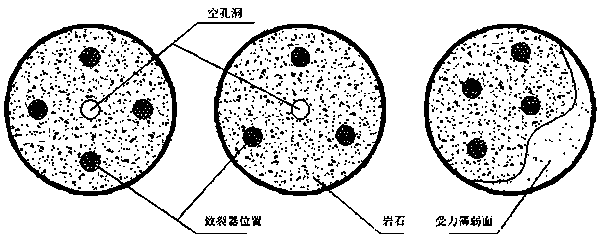

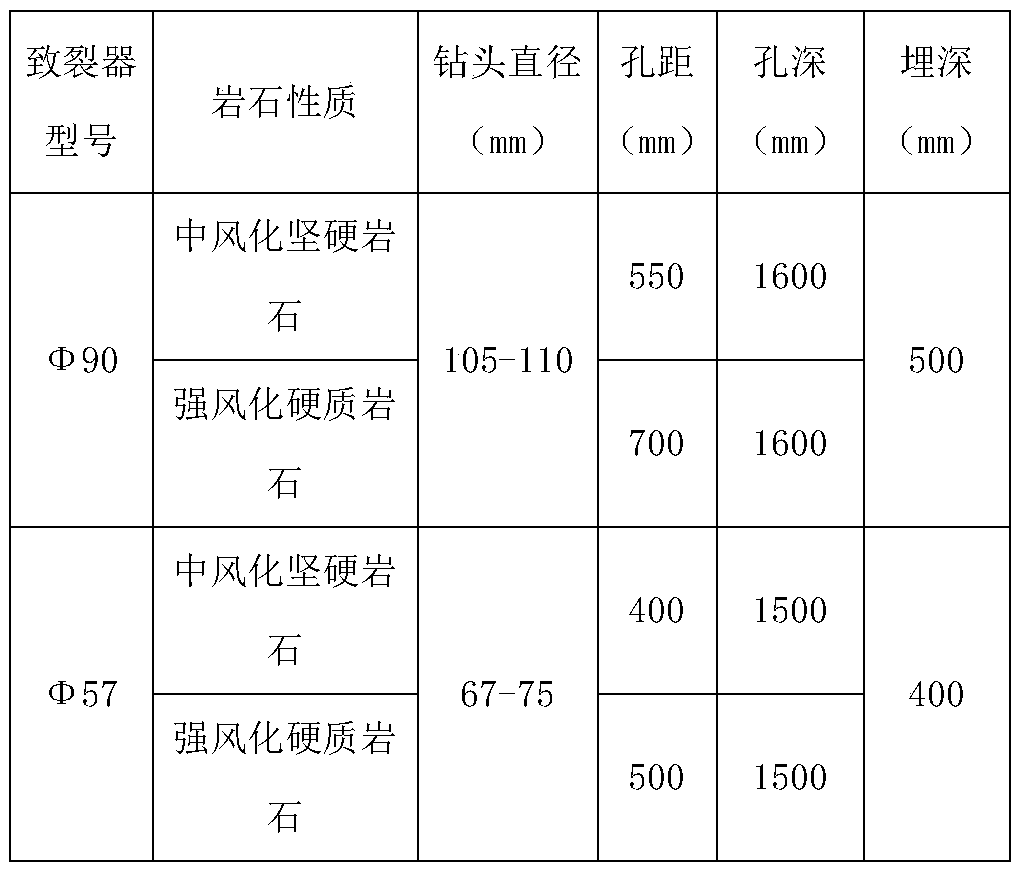

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0034] The invention provides a carbon dioxide cracking tube with drilling function, which includes a safety protection cover whose diameter is larger than that of the detonation zone, and the main body of the safety protection cover is a steel plate. Specifically, the thickness of the main steel plate of the safety protection cover is 3mm-5mm, and the diameter is 2.2m-2.5m. In the embodiment provided by the present invention, the thickness of the main steel plate of the safety protection cover is 3mm, and the diameter is 2.2m; the upper and lower layers of the steel plate are wrapped with detachable barbed wire; Straight up and equal-height springs, the height of the spring is 20-40cm; the spring top is hung with a wire mesh as large as the safety cover; the wire mesh wrapped on the steel plate is larger than the mesh diameter of the wire mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com