Processing method and system for operating data of industrial equipment

An industrial equipment and data processing technology, applied in the field of data processing, can solve the problems of low data analysis and analysis accuracy, etc., to achieve the effect of improving prediction results, improving user experience, and improving analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

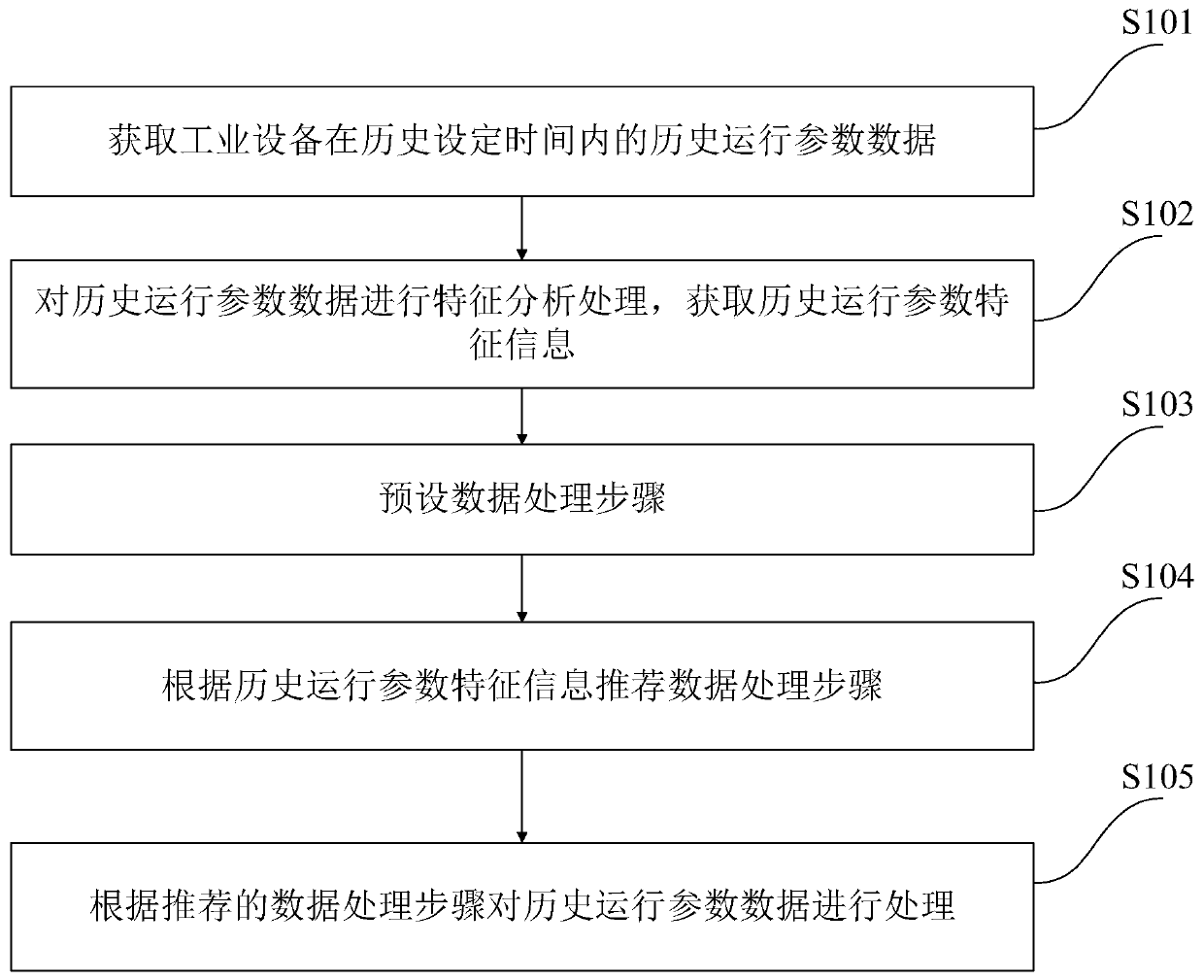

[0073] Such as figure 1 As shown, the processing method of operating data of industrial equipment in this embodiment includes:

[0074] S101. Obtain historical operating parameter data of the industrial equipment within a historical set time;

[0075] S102. Perform feature analysis and processing on historical operating parameter data, and obtain historical operating parameter feature information;

[0076] S103, preset data processing steps;

[0077] Among them, the data processing steps are set in one-to-one correspondence with different historical operating parameter characteristic information.

[0078] S104: Recommend data processing steps based on historical operating parameter characteristic information;

[0079] S105: Process historical operating parameter data according to the recommended data processing steps;

[0080] That is, based on the specific characteristic information of the historical operating parameter data, automatically recommend which data processing steps to take fo...

Embodiment 2

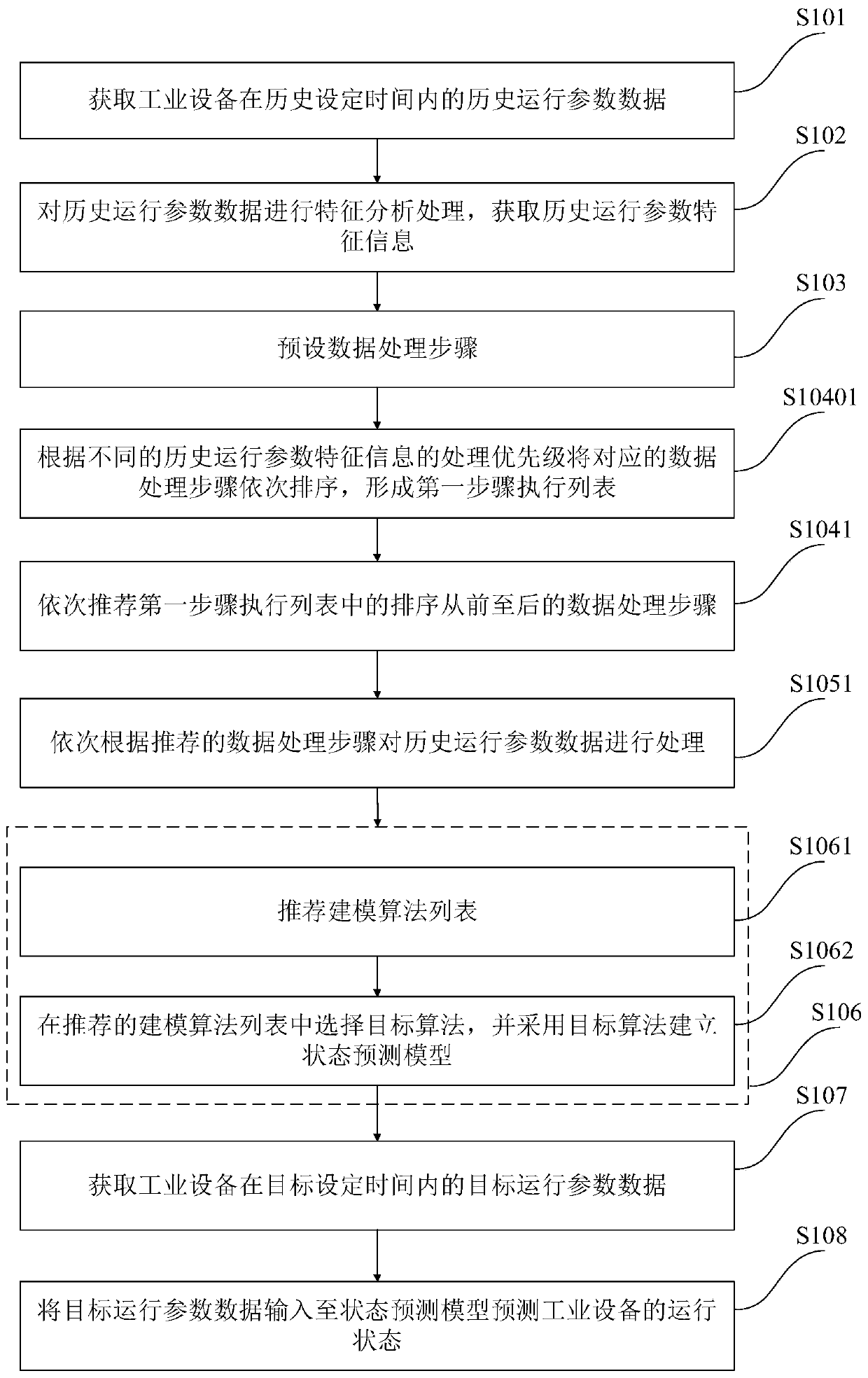

[0084] Such as figure 2 As shown, the processing method of the operating data of the industrial equipment in this embodiment is a further improvement of Embodiment 1. Specifically:

[0085] Different historical operating parameter characteristic information corresponds to different processing priorities.

[0086] After step 103 and before step S104, the method further includes:

[0087] S10401. Sort the corresponding data processing steps in sequence according to the processing priority of different historical operating parameter characteristic information to form a first step execution list;

[0088] Step S104 includes:

[0089] S1041. Recommend the first step in sequence to perform the data processing steps sorted from front to back in the list;

[0090] Step S105 includes:

[0091] S1051, sequentially process historical operating parameter data according to the recommended data processing steps.

[0092] For example: when the operating parameter feature information includes missing val...

Embodiment 3

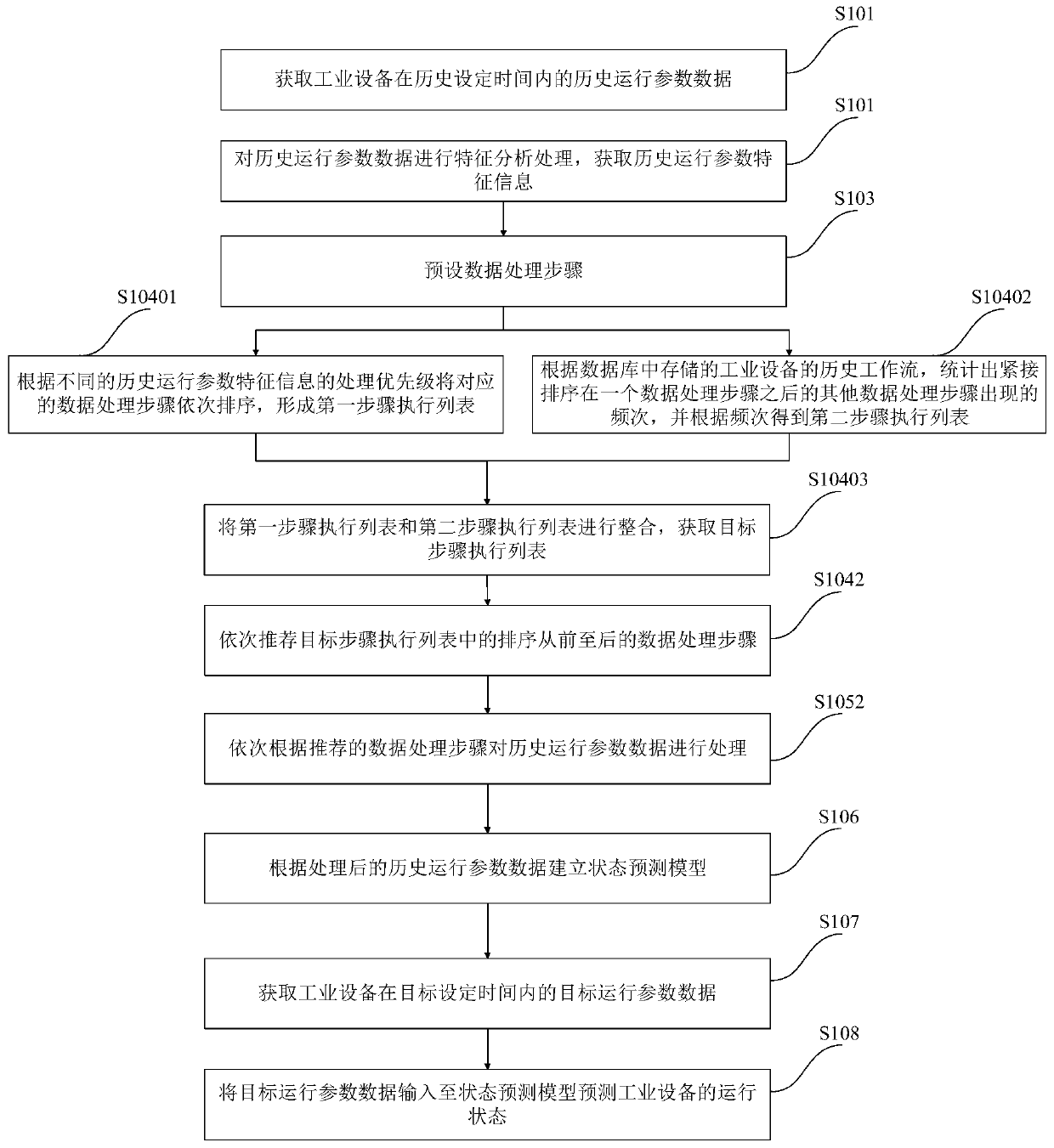

[0109] Such as image 3 As shown, the processing method of operating data of industrial equipment in this embodiment is a further improvement of Embodiment 1, specifically:

[0110] In this embodiment, the first step in embodiment 2 is used to execute the list.

[0111] Step S103 and then before step S104 further include:

[0112] S10402: According to the historical workflow of the industrial equipment stored in the database, count the frequency of occurrence of other data processing steps that are sorted immediately after one data processing step, and obtain a second step execution list according to the frequency;

[0113] S10403. Integrate the first step execution list and the second step execution list to obtain the target step execution list;

[0114] Among them, the processing priority of the data processing steps appearing in the first step execution list and the second step execution list at the same time is the highest;

[0115] The processing priority of the data processing step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com