Stress analysis method for tubular busbar, downlead and hardware system

A stress analysis and down-conductor technology, applied in the field of substation, can solve the problems of pipe busbar and down-conductor coupling consideration, non-linear deformation of down-conductor, etc., and achieve the effect of perfect layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A stress analysis method for pipe busbar, down conductor and fitting system, comprising:

[0038] 1 Numerical simulation of pipe bus down conductor system

[0039] 1.1 Parameters of pipe bus down conductors

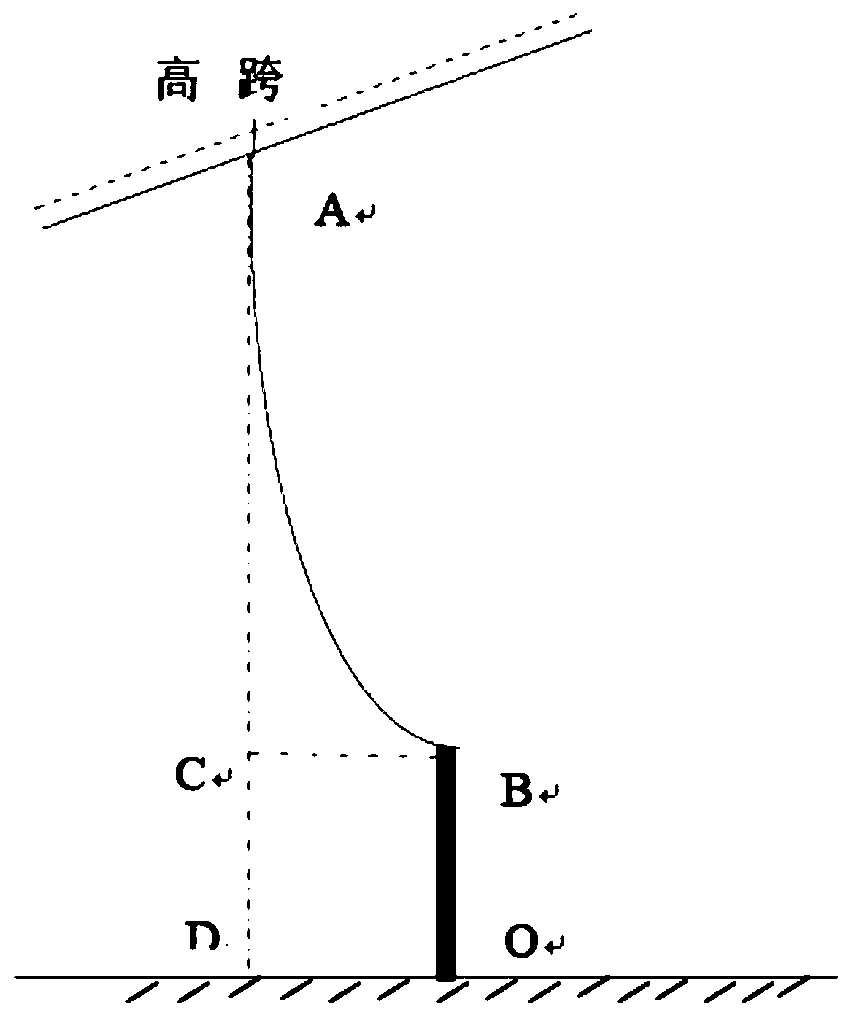

[0040] Referring to a real case, on June 23, 2016, a substation operation and maintenance personnel found that a certain isolating switch B phase I bus side transition tube parent fixing hardware was broken, and the substation was put into operation on October 23, 2015. For the specific layout of the pipe bus down conductor system, see figure 1 , figure 2 .

[0041] Such as figure 1 As shown, the bus downconductor of the transition pipe on the bus side of Phase B I bends along the wind direction, and the length of the downconductor is greater than 13 meters according to the construction drawing. Such as figure 2 As shown, one end of the transition tube on the B-phase I bus side is connected to the supporting insulator in a sliding manner (the connecting har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com