Heterojunction solar cell with plated seed layer prepared by in-situ reduction, and preparation method thereof

A technology of solar cells and seed layers, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex processes and many consumables, and achieve the effects of good uniformity, reduced interface contact resistance, and reduced process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

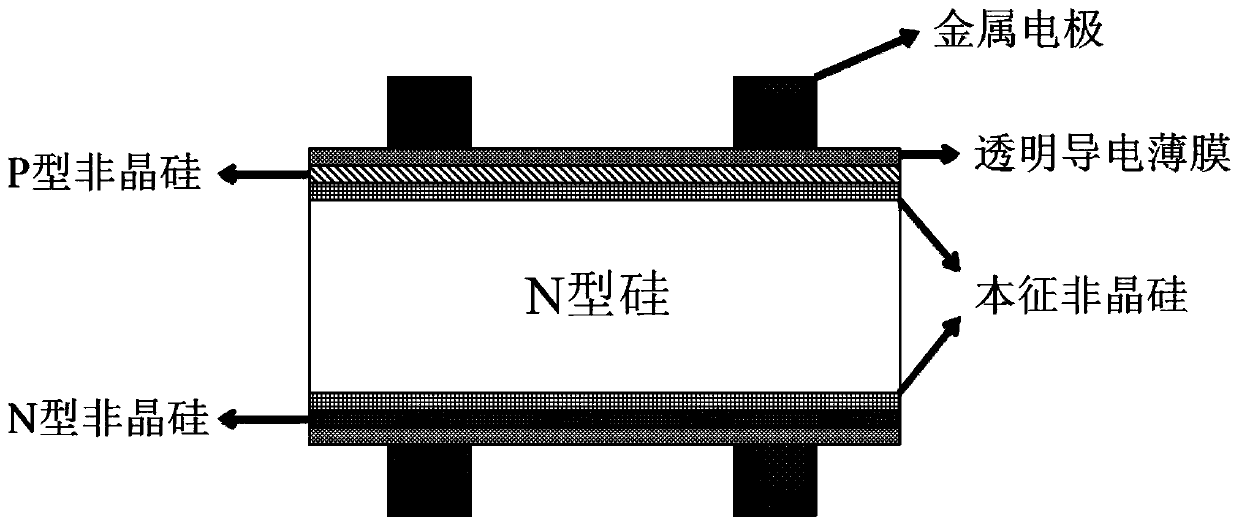

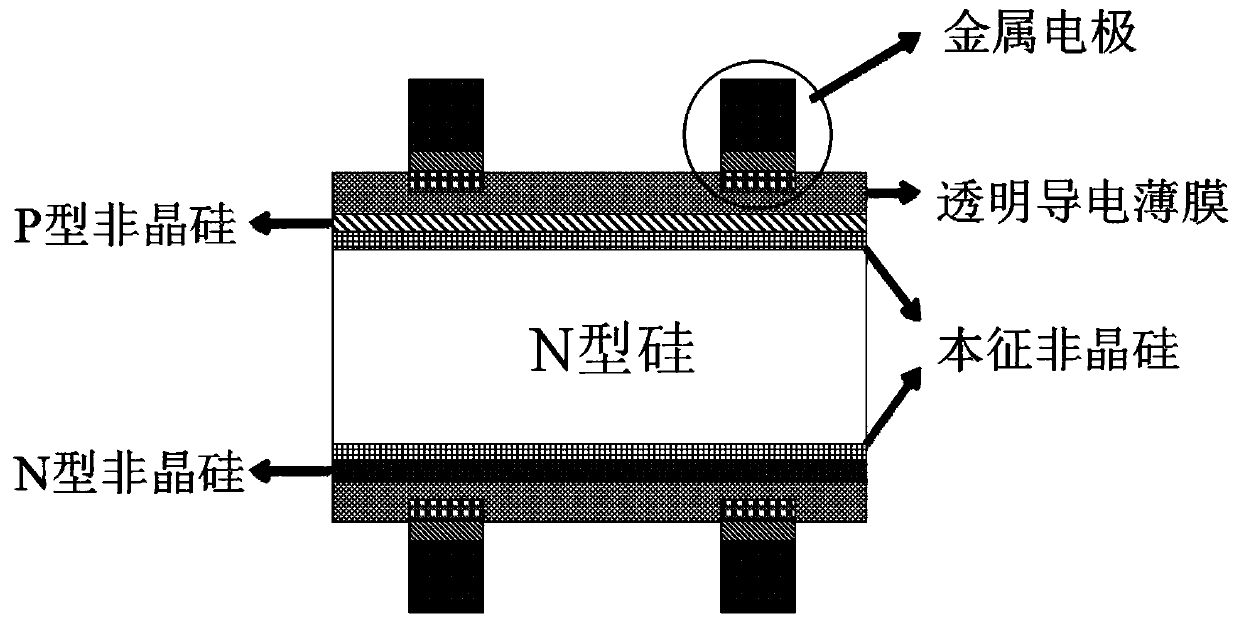

[0047] Such as image 3 and 4 As shown, a heterojunction solar cell for preparing an electroplating seed layer by in-situ reduction of the present invention has the following structure:

[0048] Cu / Ni / In / ITO / p-a-Si / i-a-Si / n-c-Si / i-a-Si / n-a-Si / ITO / In / Ni / Cu, where Cu is metal copper, Ni is metal nickel, and In is metal Indium, ITO is tin-doped indium oxide transparent conductive film, p-a-Si is P-type amorphous silicon film, i-a-Si is intrinsic amorphous silicon film, n-c-Si is N-type single crystal silicon substrate, n-a-Si It is an N-type amorphous silicon film.

[0049] The preparation process of this embodiment is as follows Figure 6 Shown:

[0050] (1) Perform damage removal and surface texturing on the N-type single crystal silicon substrate layer;

[0051] (2) Depositing an intrinsic amorphous silicon film on both side surfaces of the N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap