Bearingless asynchronous motor inverse decoupling control system based on online rotor resistance identification

A rotor resistance, asynchronous motor technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the influence of rotor resistance parameter decoupling control performance, rotor flux linkage observation error, affecting air gap flux linkage Accuracy system dynamic decoupling control performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

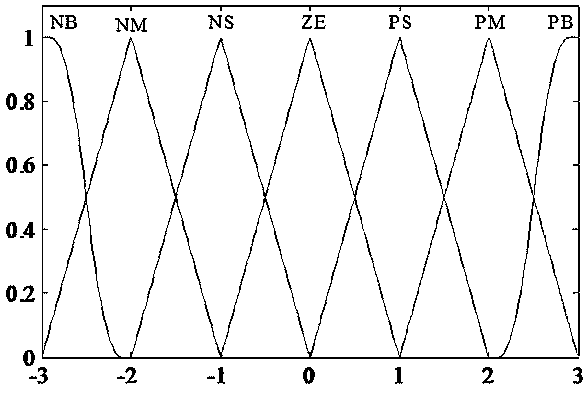

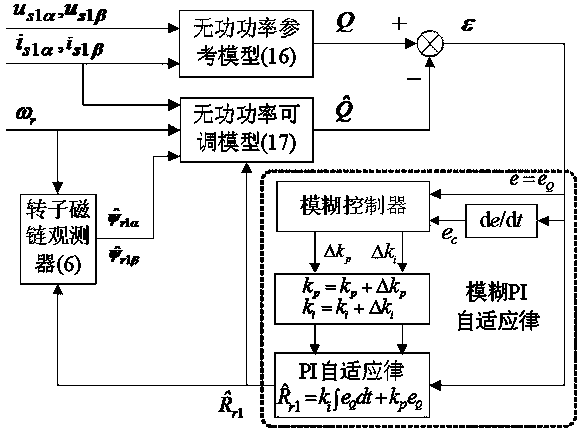

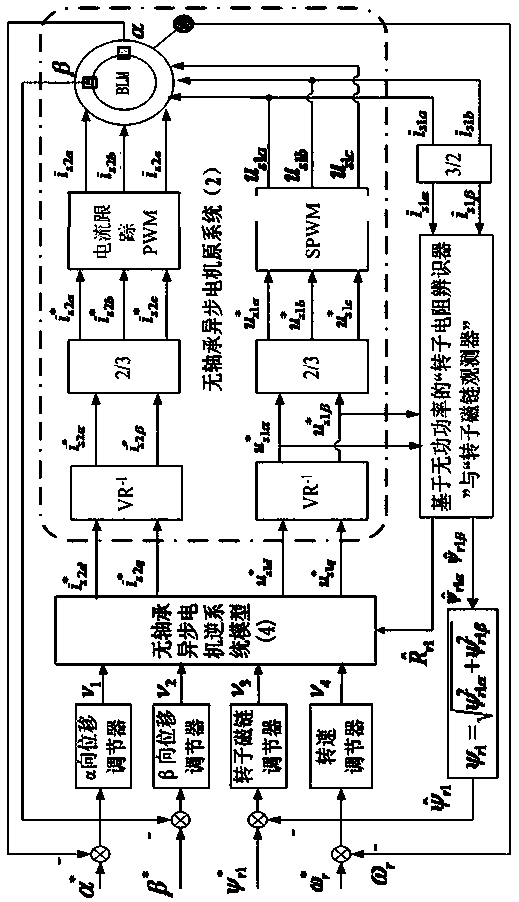

[0063] The inverse decoupling control system of a bearingless asynchronous motor based on the online identification of rotor resistance firstly derives a reference model and an adjustable model of the reactive power of the torque system in the stationary coordinate system, and its "reference model" does not include parameters of the stator resistance , pure integral link; then, construct the rotor resistance "fuzzy PI adaptive law" based on Popov's ultra-stable theory, in order to effectively improve the real-time speed and accuracy of rotor resistance identification; finally, the inverse system model of the bearingless asynchronous motor, In the rotor flux observation model, the rotor resistance parameters are corrected in real time in order to effectively improve its dynamic decoupling control performance. It belongs to the field of parameter online detection and drive control technology of new special motors, and is especially suitable for high-performance dynamic decoupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com