Water-permeable glue gelling agent and processing method

A gelling agent and water-retaining agent technology, applied in the field of gelling agent, can solve the problems of poor water permeability and adhesion of the gelling agent, and achieve good water retention and permeability, enhanced strength, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A water-permeable gel agent, comprising ammonium sulfate, sodium sulfate, potassium sulfate, magnesium chloride, sodium silicate, calcium sulfate, polyferric sulfate, sodium gluconate, water retaining agent, water-soluble starch and water, the composition ratio of the above raw materials Ammonium sulfate 3%, sodium sulfate 2%, potassium sulfate 3%, magnesium chloride 2%, sodium silicate 2%, calcium sulfate 18%, polyferric sulfate 2%, sodium gluconate 2%, water retaining agent 1%, water soluble Starch 5% and water 60%.

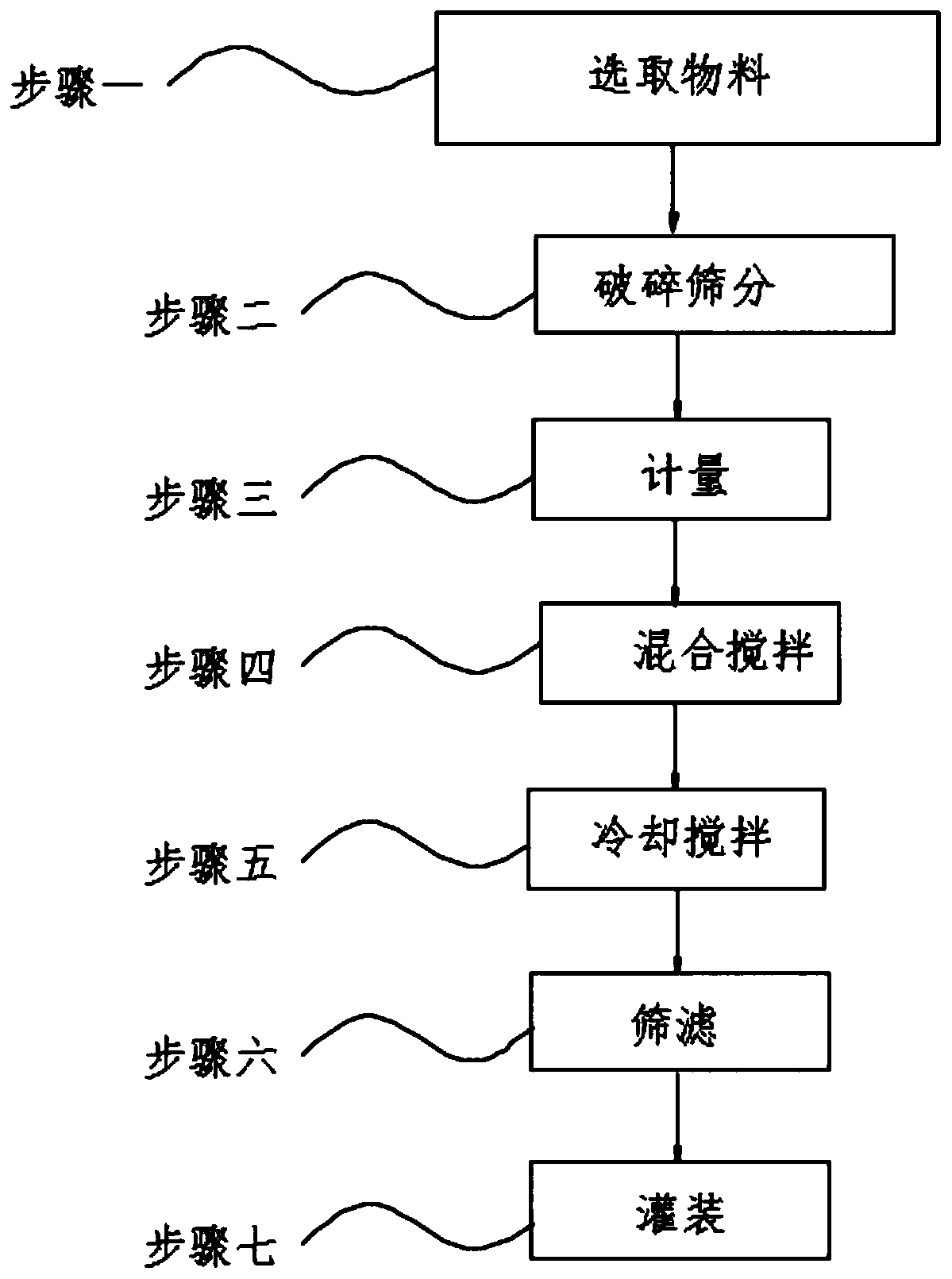

[0023] A processing technology of water-permeable glue gel, comprising the following steps: Step 1, selecting materials; Step 2, crushing and screening; Step 3, measuring; Step 4, mixing and stirring; Step 5, cooling and stirring; Step 6, sieving ;Step seven, filling;

[0024] Wherein in above-mentioned step one, according to ammonium sulfate 3%, sodium sulfate 2%, potassium sulfate 3%, magnesium chloride 2%, sodium silicate 2%, calcium sulfate 18%, pol...

Embodiment 2

[0032] A water-permeable gel agent, comprising ammonium sulfate, sodium sulfate, potassium sulfate, magnesium chloride, sodium silicate, calcium sulfate, polyferric sulfate, sodium gluconate, water retaining agent, water-soluble starch and water, the composition ratio of the above raw materials Ammonium sulfate 3%, sodium sulfate 2%, potassium sulfate 3%, magnesium chloride 2%, sodium silicate 2%, calcium sulfate 18%, polyferric sulfate 2%, sodium gluconate 2%, water retaining agent 2%, water soluble Starch 4% and water 60%.

[0033] A processing technology of water-permeable glue gel, comprising the following steps: Step 1, selecting materials; Step 2, crushing and screening; Step 3, measuring; Step 4, mixing and stirring; Step 5, cooling and stirring; Step 6, sieving ;Step seven, filling;

[0034] Wherein in above-mentioned step one, according to ammonium sulfate 3%, sodium sulfate 2%, potassium sulfate 3%, magnesium chloride 2%, sodium silicate 2%, calcium sulfate 18%, pol...

Embodiment 3

[0042] A water-permeable gel agent, comprising ammonium sulfate, sodium sulfate, potassium sulfate, magnesium chloride, sodium silicate, calcium sulfate, polyferric sulfate, sodium gluconate, water retaining agent, water-soluble starch and water, the composition ratio of the above raw materials Ammonium sulfate 3%, sodium sulfate 2%, potassium sulfate 3%, magnesium chloride 2%, sodium silicate 2%, calcium sulfate 18%, polyferric sulfate 2%, sodium gluconate 2%, water retaining agent 3%, water soluble Starch 3% and water 60%.

[0043] A processing technology of water-permeable glue gel, comprising the following steps: Step 1, selecting materials; Step 2, crushing and screening; Step 3, measuring; Step 4, mixing and stirring; Step 5, cooling and stirring; Step 6, sieving ;Step seven, filling;

[0044] Wherein in above-mentioned step one, according to ammonium sulfate 5%, sodium sulfate 3%, potassium sulfate 5%, magnesium chloride 3%, sodium silicate 3%, calcium sulfate 20%, pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com