Method for preventing cast-in-place pile cage floating and adopted reinforced concrete base

A technology of reinforced concrete and cast-in-place piles, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve problems such as unsatisfactory solutions, and achieve the effect of improving the quality of pile bottoms and ensuring reliable quality of pile bottoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

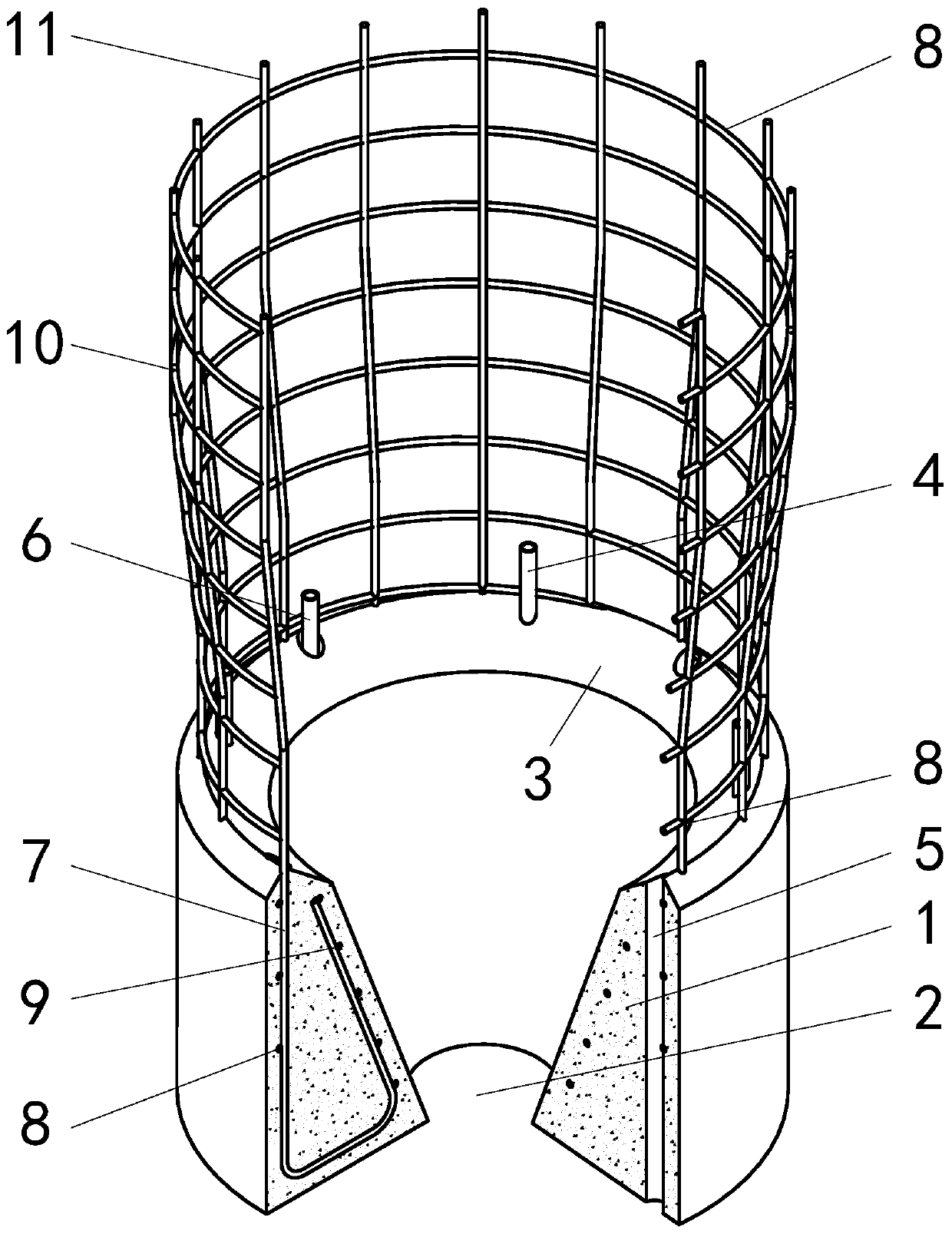

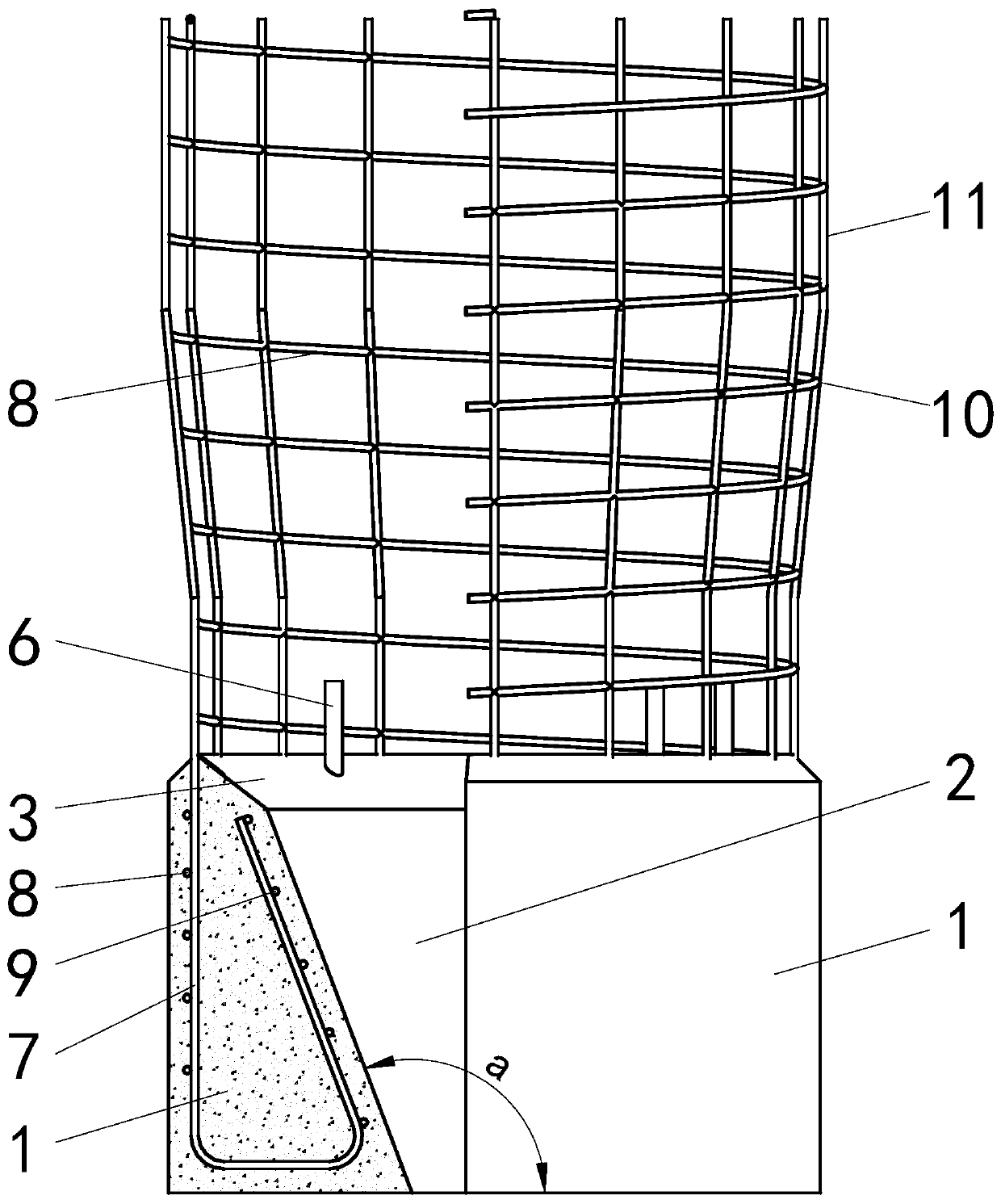

[0025] This example figure 1 and figure 2 As shown, the main rib 7 is included, and the main rib 7 is a hook-shaped steel bar, which is similar in shape to a right triangle. The number and diameter of the main reinforcement 7 are the same as the number of the longitudinal reinforcement 11 on the reinforcement cage 10 . After the processing of the main reinforcement 7 is completed, all the main reinforcement 7 are bound or welded as a whole through the spiral stirrup 8 and the ring reinforcement 9 . After the steel bars are connected, set up the formwork according to the size of the cast-in-place pile, and install the acoustic tube 2 and the grouting tube 6, and then pour the reinforced concrete base 1. The strength grade of the concrete used for the reinforced concrete base 1 is not lower than C30, which is the design strength The larger of the grades. The reinforced concrete base 1 can only be connected with the steel cage 10 after the solidification period reaches 28 day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com