Recyclable assembled foundation pit support structure

A foundation pit supporting and prefabricated technology, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as high cost, economic waste, tedious installation and disassembly, etc., to solve waterproof problems, avoid potential safety hazards, and fast construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

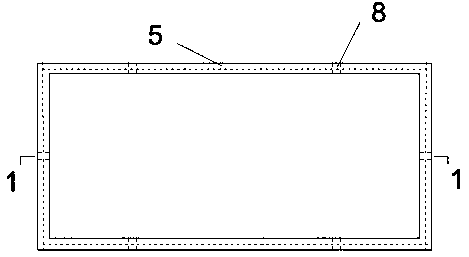

[0023] Example: such as Figure 6 As shown, this structure includes a rectangular prefabricated component 1, a cross-shaped bracket 2 and a recyclable anchor rod 3; between the rectangular prefabricated component 1 and the rectangular prefabricated component 1, between the rectangular prefabricated component 1 and the cross-shaped bracket 2, and the cross-shaped bracket 2 Between them and the cross-shaped support 2, they are all connected by bolts 8, and the connecting bolts 8 of the two rectangular prefabricated components 1 spanning the cross-shaped support 2 are long bolts, passing through the cross-shaped support 2 where they are located.

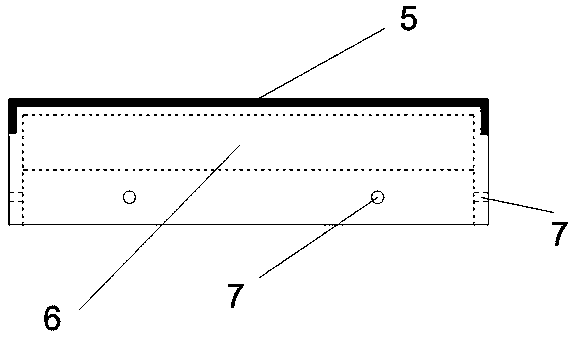

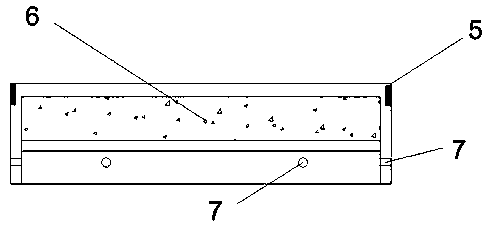

[0024] Such as Figure 1 to Figure 3 As shown, the rectangular prefabricated component 1 is a deep trough-shaped steel component with one end open, and a concrete body 6 is arranged at the rear half of the rectangular prefabricated component 1 in the depth direction, and the front end of the concrete body 6 is fixed with a steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com