Micropore detection device and using method thereof

A detection device and microporous technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems of complicated operation, increased cost, and increased detection time, and achieve good results, simple structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Below in conjunction with accompanying drawing, the present invention will be further described.

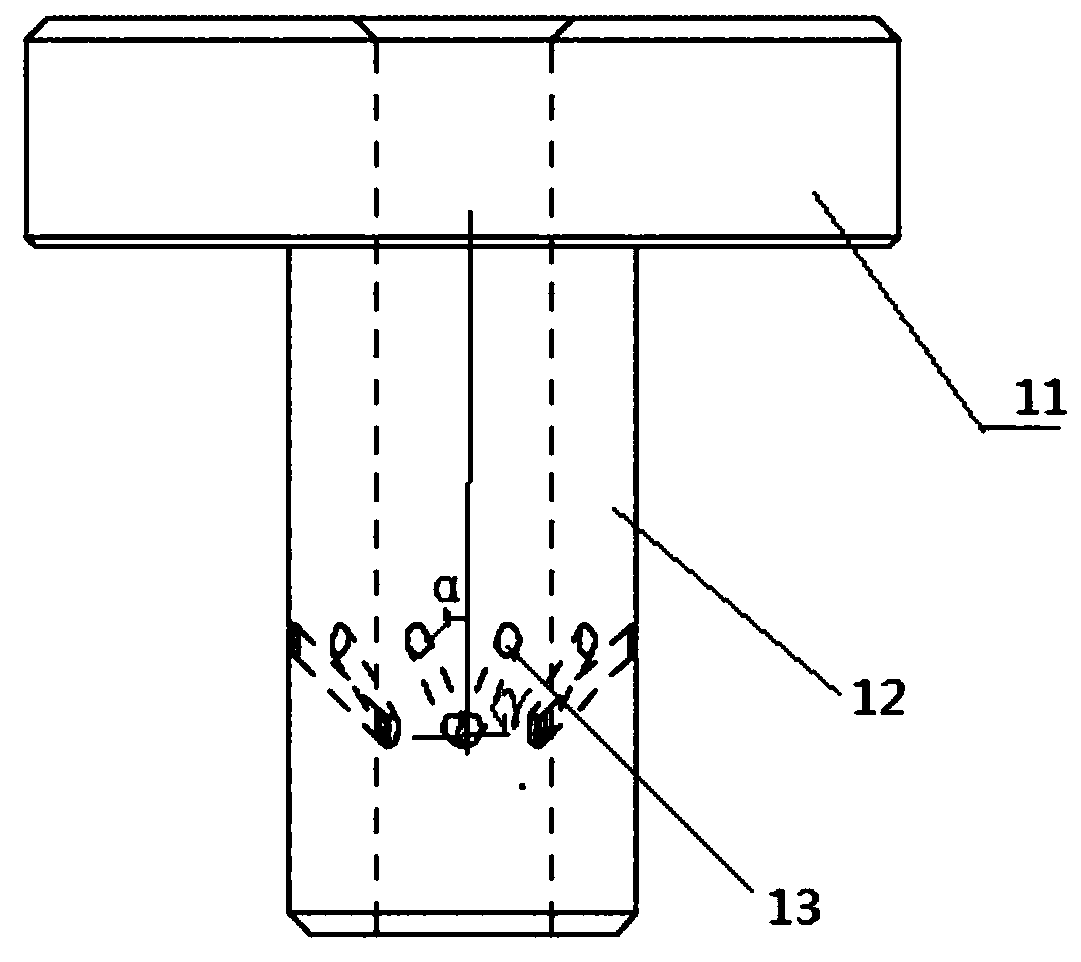

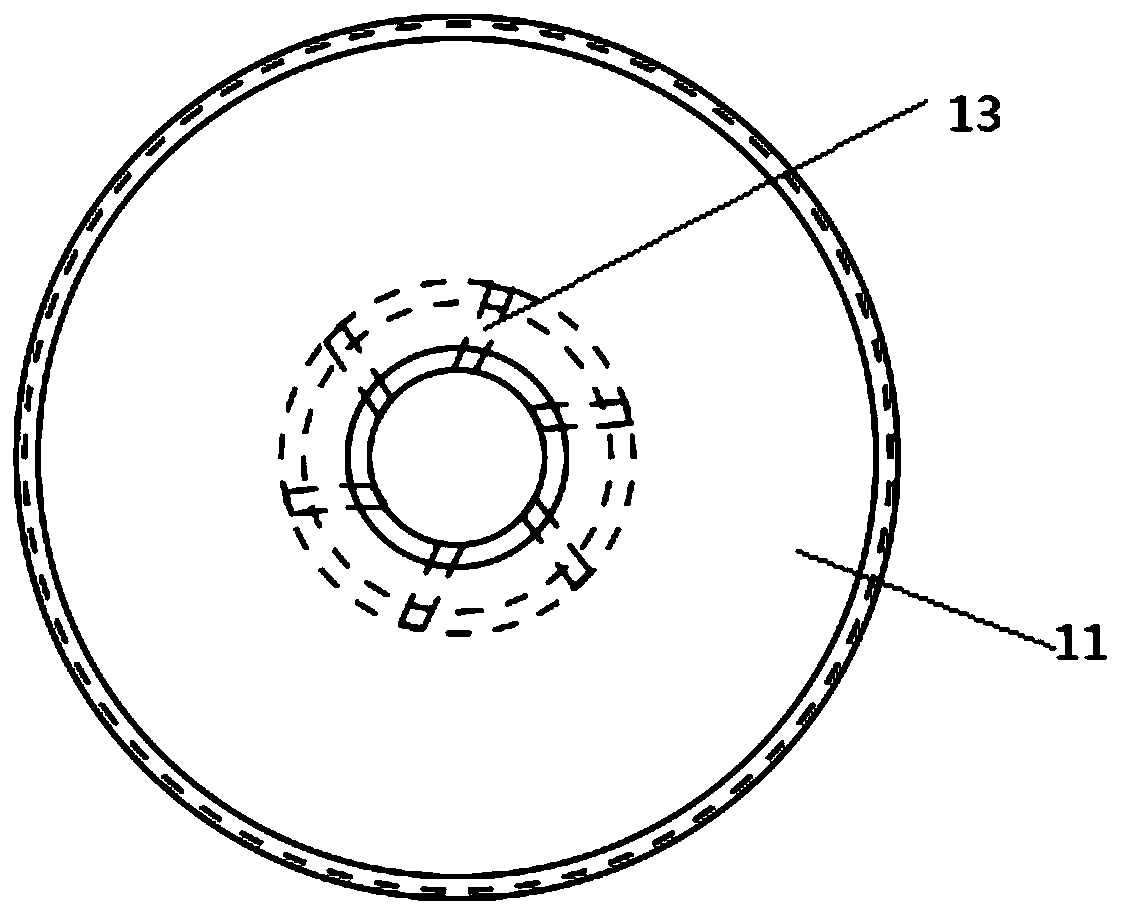

[0023] Please refer to figure 1 , figure 1 It is a front view of the detected object of the present invention. The detected object includes two parts, the detected object head (11) and the detected object main body (12). In this embodiment, the detected object main body (12) is provided with a series of microholes (13), the purpose of the microhole detection device of the present invention is exactly to detect whether the position and angle of the microholes (13) are accurate, from figure 2 It can be seen that the detected object is hollow.

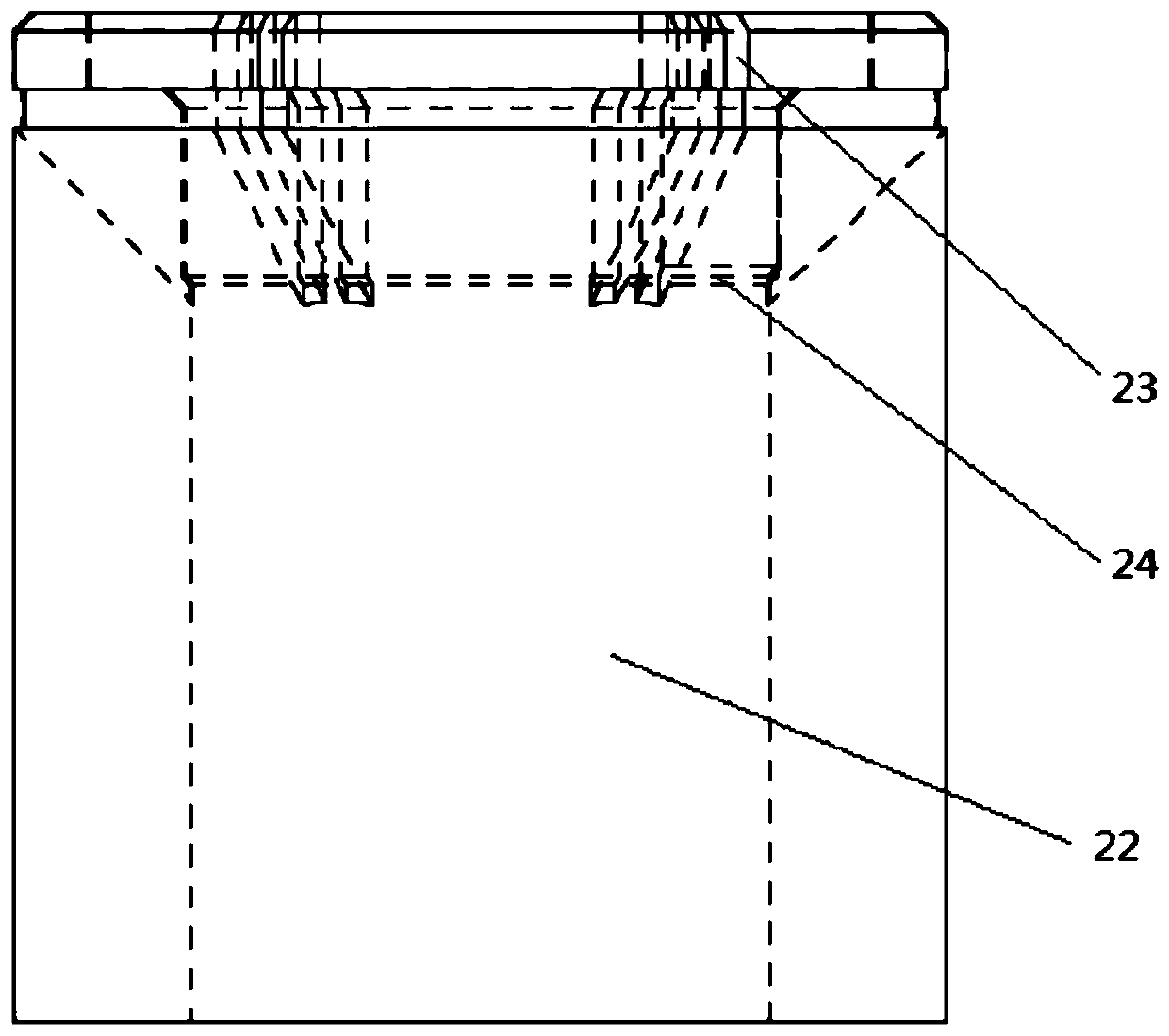

[0024] image 3 It is the detection body in the micropore detection device of the present invention. The detection body is provided with a cavity (22) for accommodating the detected object body (12), and the top of the detection body is provided with more than one The detection groove (23) used in conjunction with the needle gaug...

Embodiment 2

[0027] The second object of the present invention is to provide a method for using the above-mentioned micropore detection device, which method includes the following steps:

[0028] (1) First insert the needle gauge (3) into the microhole (13) on the main body of the detected object;

[0029] (2) Put the main body (12) of the detected object into the cavity (22), put the head of the detected object (11) on the groove (25), when placing it, put the needle gauge (3) and The position of the detection groove (23) is aligned, and the detected object sinks under the action of gravity;

[0030] (3) After sinking completely, observe whether all needle gauges (3) enter the detection groove (23). If all needle gauges (3) can enter the detection groove (23), it indicates that the microhole (13) is The position at the position is accurate, otherwise it is unqualified, and the relative position of some micropores (13) is not accurate;

[0031] (4) Observe whether the needle gauges (3) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com