Frequency tracking system for output signals of ultrasonic power supply based on fuzzy PI control technology

A technology of control technology and tracking system, which is applied in the field of ultrasonic power supply output signal frequency tracking system, which can solve the problems of severe mechanical loss of transducers, inability to meet frequency tracking correction, high precision, fast response, and transducer tracking, etc., to achieve accurate and the effect of fast tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

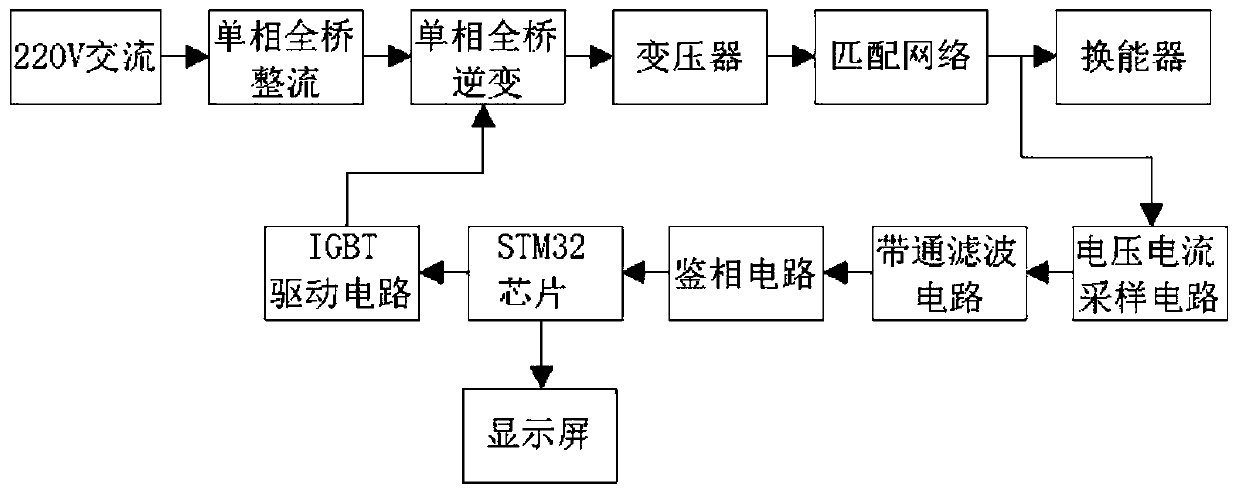

[0049] The ultrasonic power supply output signal frequency tracking system (hereinafter referred to as the tracking system) based on fuzzy PI control technology provided by the present invention is composed of hardware circuit and software program, wherein, fuzzy PI control technology (i.e. fuzzy PI algorithm) is in the form of software program accomplish.

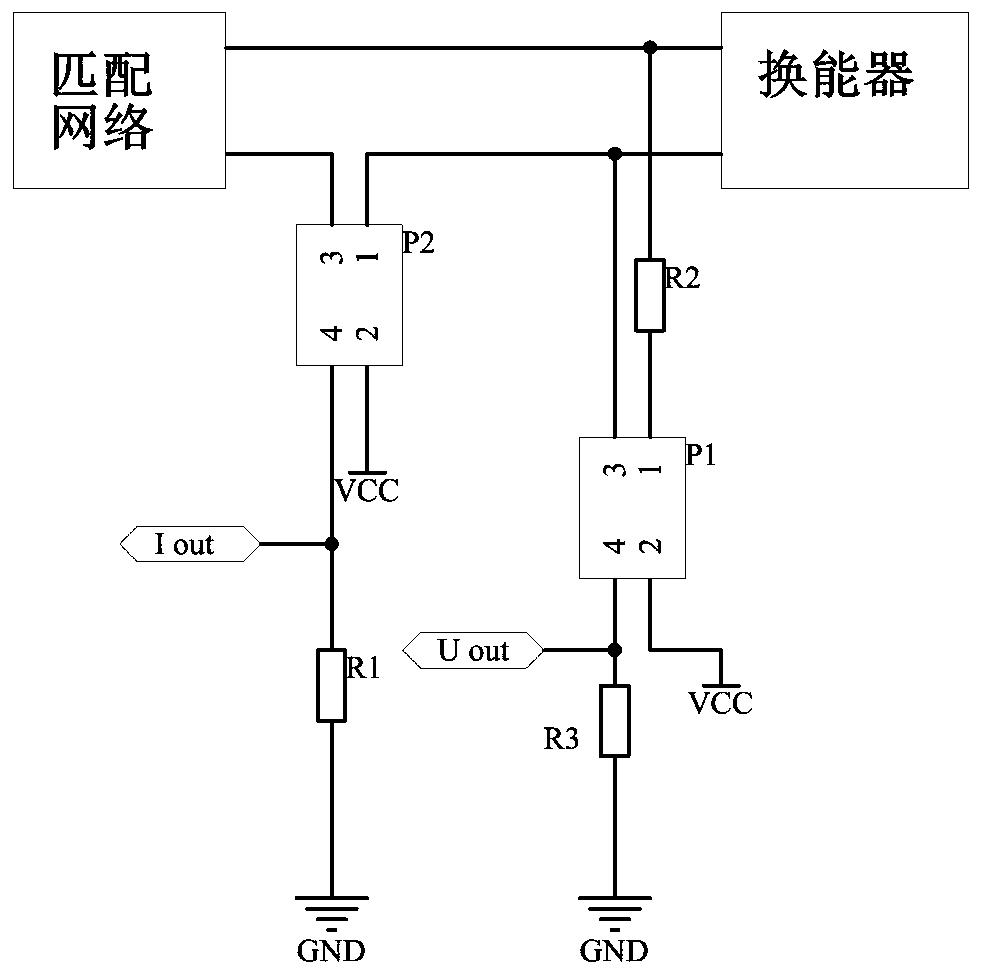

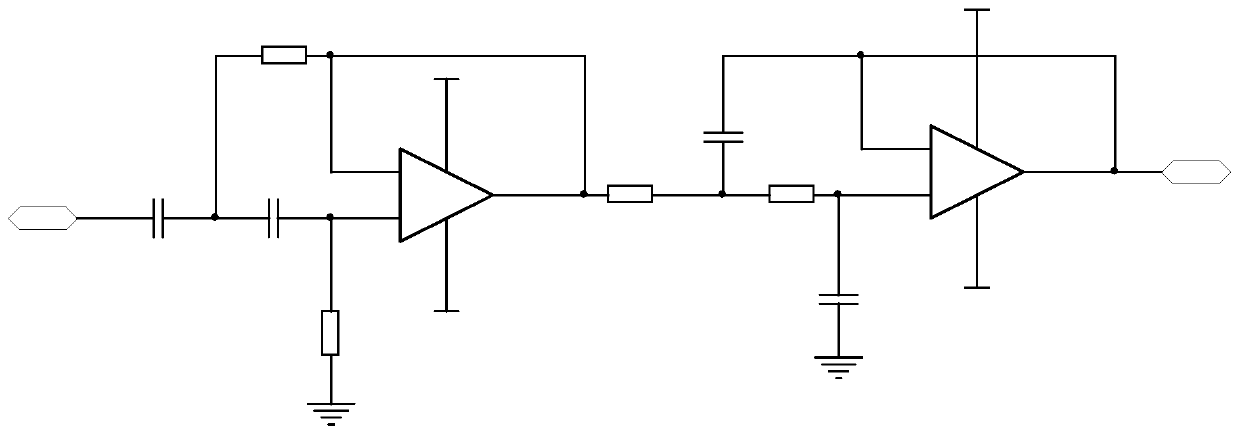

[0050] Working principle: When the ultrasonic power supply is working in a detuned state, there is a certain phase difference between the voltage and current flowing through the two ends of the transducer, and when the ultrasonic power supply is working in a resonant state, the voltage and current flowing through the two ends of the transducer have a phase difference It is zero, indicating that the frequency of the signal output by the inverter is consistent with the resonant frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com