A Method for Quickly Introducing Functional Ions on Titanium Alloy Surface

A titanium alloy and functional technology, applied in the surface functional modification treatment of titanium alloy medical implant materials, in the field of biomedicine, can solve the problem of low bonding strength between the coating and the substrate, the inability to prepare a uniform coating, and the poor bonding force of the coating and other problems, to achieve the effect of simple and rapid introduction method, low cost and good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

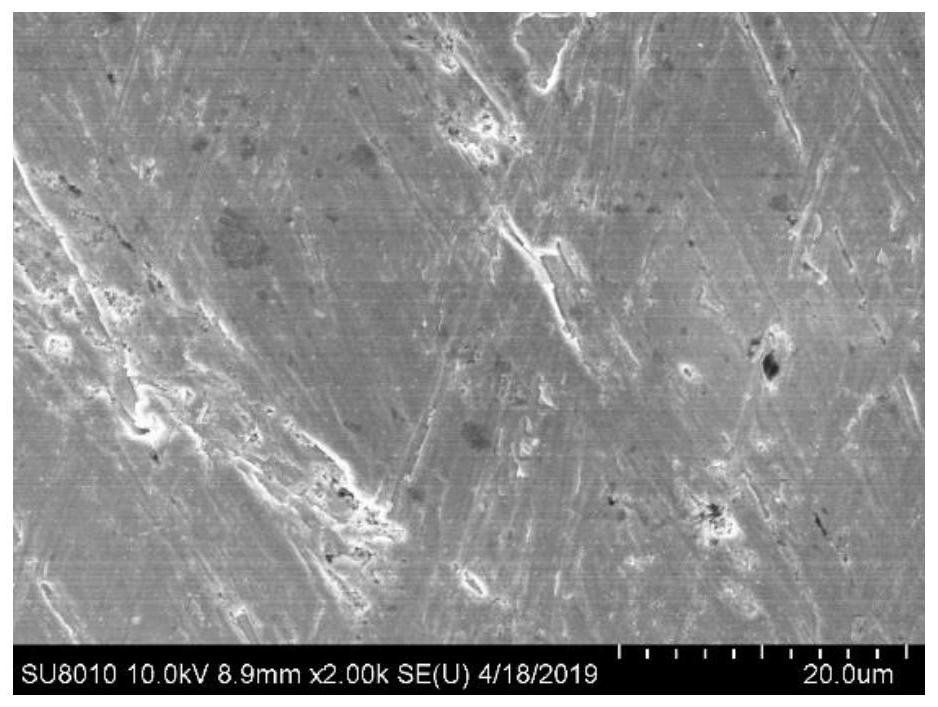

[0041] The TC4 sample (diameter 12mm, thickness 2mm) is punched (hole diameter 2mm), and then polished with 400, 1200, 2000 mesh silicon carbide sandpaper in order to ensure that the surface is free of scale and smooth. Then, they were ultrasonically cleaned with ethanol and deionized water for 10 minutes respectively, and the pretreatment was completed after drying. The pretreated TC4 sample was used as the electrolytic anode and immersed in the micro-arc oxidation electrolyte, and the electrolytic cell was used as the electrolytic cathode. The electrolyte was 6.12g of β-glycerophosphate sodium, 35.2g of calcium acetate and 1.0L of deionized water. The temperature of the electrolyte is controlled at 12°C, and a square pulse is applied to the TC4 sample to make the electrolytic anode interact with the electrolyte solution to form a ceramic film. The positive pulse voltage of the square pulse is 350V, and the negative pulse voltage of the square pulse is 50V. Both the positive ...

Embodiment 2

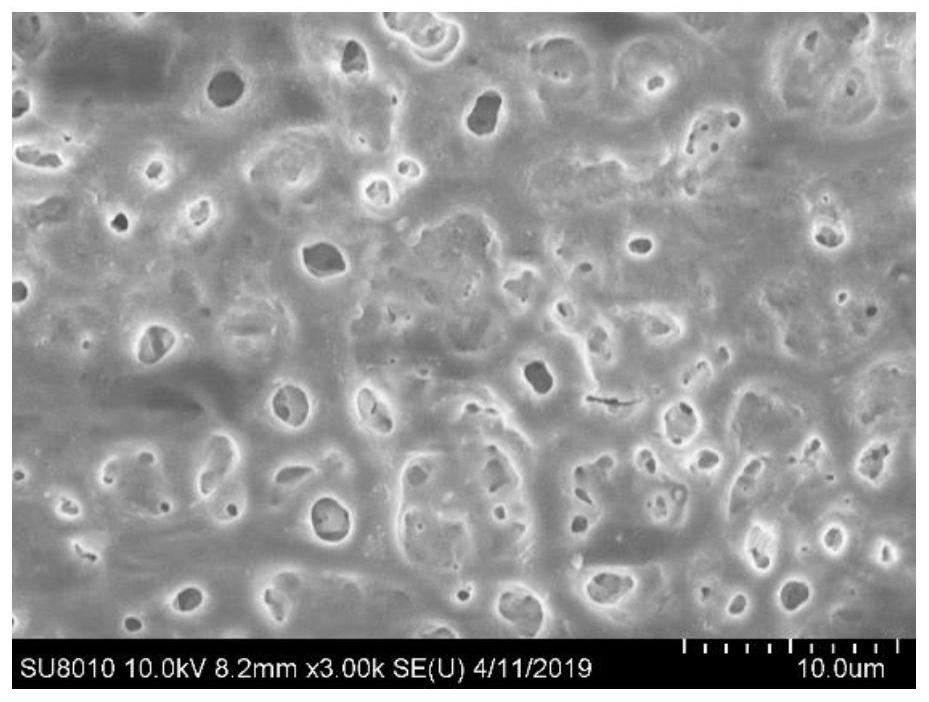

[0044] The TC4 sample (diameter 12mm, thickness 2mm) is punched (hole diameter 2mm), and then polished with 400, 1200, 2000 mesh silicon carbide sandpaper in order to ensure that the surface is free of scale and smooth. Then, they were ultrasonically cleaned with ethanol and deionized water for 10 minutes respectively, and the pretreatment was completed after drying. The pretreated TC4 sample was used as the electrolytic anode and immersed in the micro-arc oxidation electrolyte, and the electrolytic cell was used as the electrolytic cathode. The electrolyte was 4.5g of β-glycerophosphate sodium, 40g of calcium gluconate and 1.0L of deionized water. Control the electrolyte temperature to 12°C, apply a square pulse on the TC4 sample to make the electrolytic anode interact with the electrolyte solution to form a ceramic film, the positive pulse voltage of the square pulse is 250V, and the negative pulse voltage of the square pulse is 30V; the positive pulse voltage and The freque...

Embodiment 3

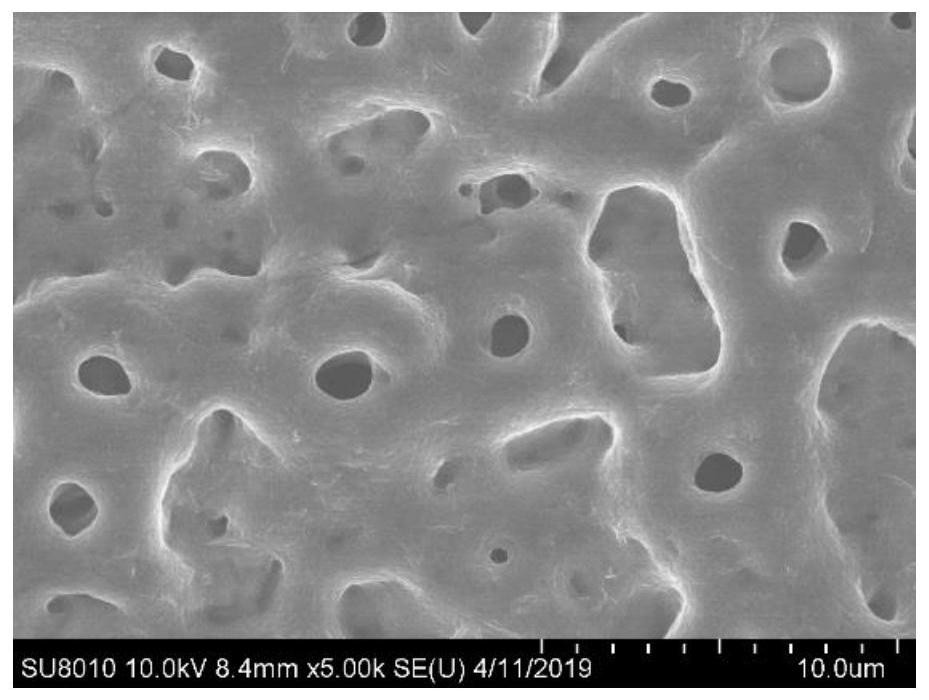

[0047] 10 g of copper gluconate and 5 g of boric acid were added to 100 mL of water, and the pH of the solution was adjusted to 7 with ammonia water (mass fraction 28%). The prepared solution was transferred to a reactor, and TC4 after micro-arc oxidation in Example 1 was immersed in the solution, and the reactor was heated at 130° C. for 10 h. When the reaction system was naturally cooled to room temperature, TC4 was taken out, and TC4 was ultrasonicated in deionized water for 20 minutes, rinsed with deionized water, and finally dried in a vacuum oven at 50°C for 3 hours to prepare a calcium phosphate ceramic coating containing copper ions on the surface of TC4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com